Method of operating a strip coiler and strip coiler operated thereby

A strip coiling machine and strip coiling technology, applied in the direction of winding mechanism, textile and papermaking, fiber processing, etc., can solve impossible and difficult problems, achieve quality improvement and reduce the risk of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

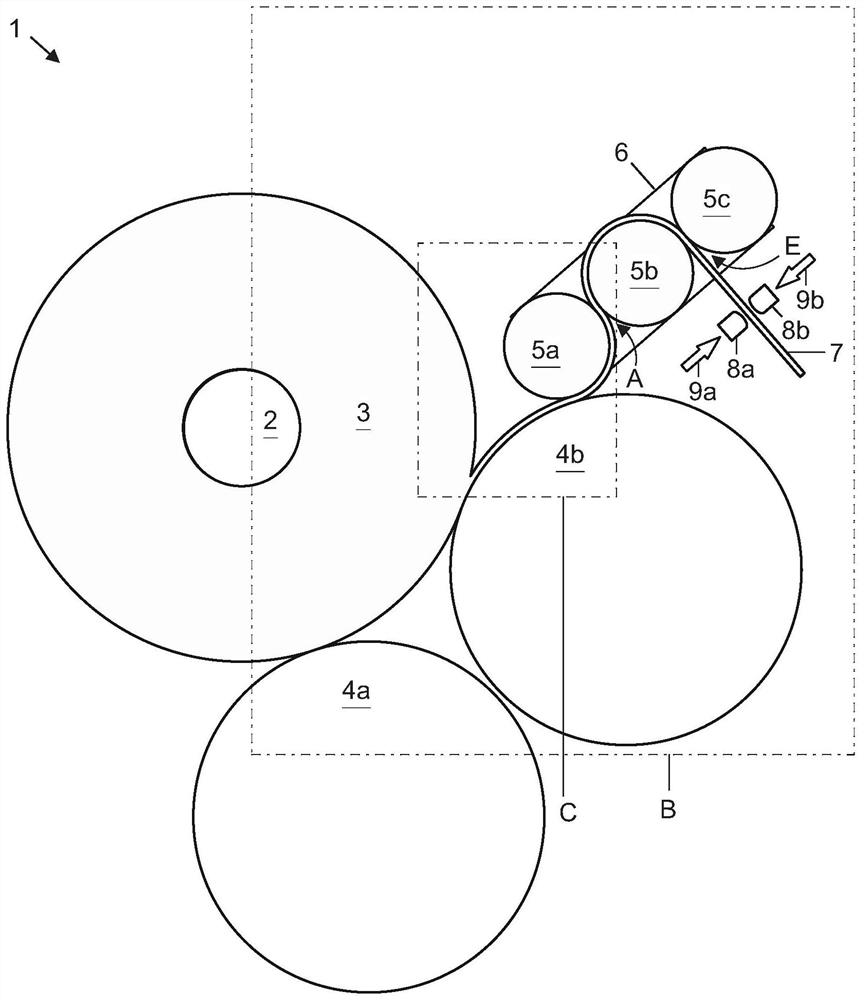

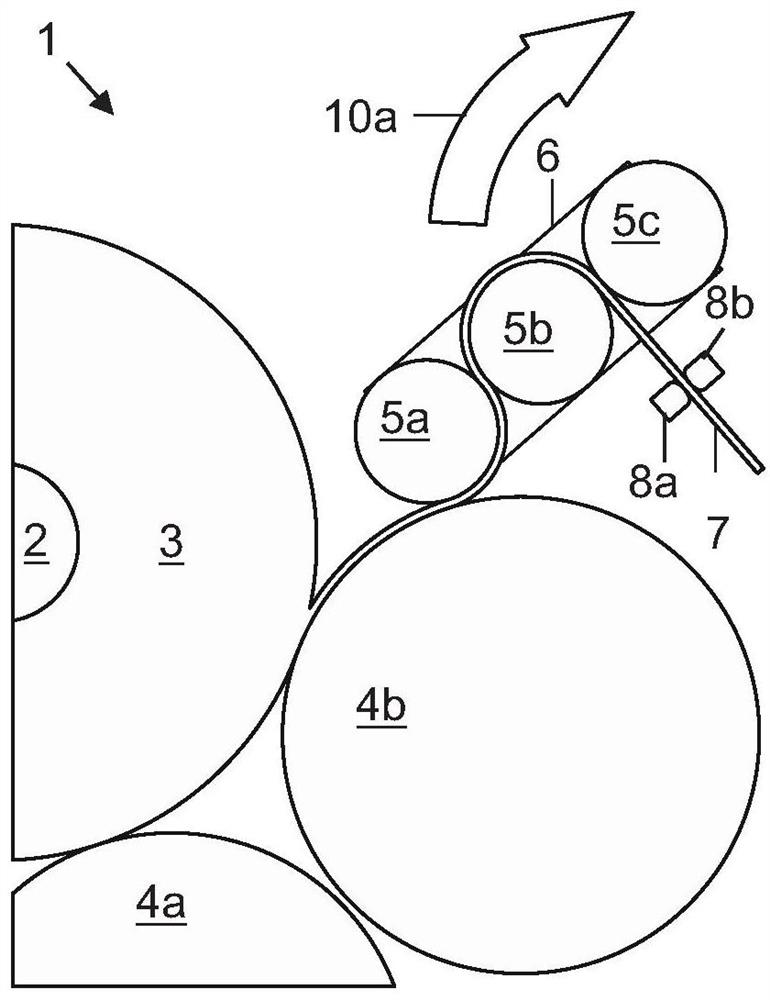

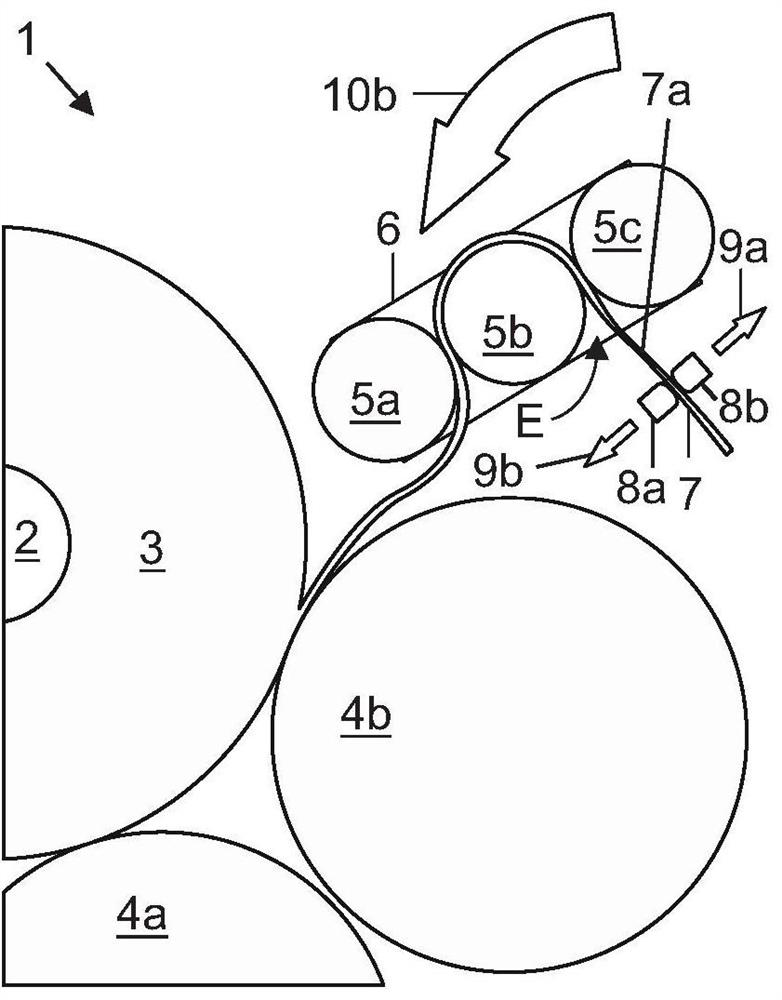

[0035] figure 1 A sliver coiler 1 according to a first embodiment of the invention is shown and has only the components which are essential for the invention. For the sake of clarity, other components such as creel, drafting device etc. are not shown.

[0036] The sliver 7 comes from a drafting device (not shown), indicated here by the blank end on the right, and passes through a pressing device provided here with three pressing rollers 5 a - 5 c . The pressure rollers 5 a - 5 c are driven and freely rotatably mounted on the frame 6 in the usual manner. In this case, the pressure rollers 5 b , 5 c form, in their region facing the free end of the sliver 7 , the inlet E of the pressure roller arrangement. The sliver leaves the nip roll arrangement at outlet A of the arrangement and touches the nearest lap roller 4b of a not further indicated lap arrangement, here in the form of two lap rollers 4a, 4b form of the device. The sliver 7 passes through the lap rollers to the bobb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com