High-pressure pump

A technology for high-pressure pumps and pump pistons, applied to pumps, multi-cylinder pumps, fuel injection pumps, etc., to achieve the effect of reducing guide diameter and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

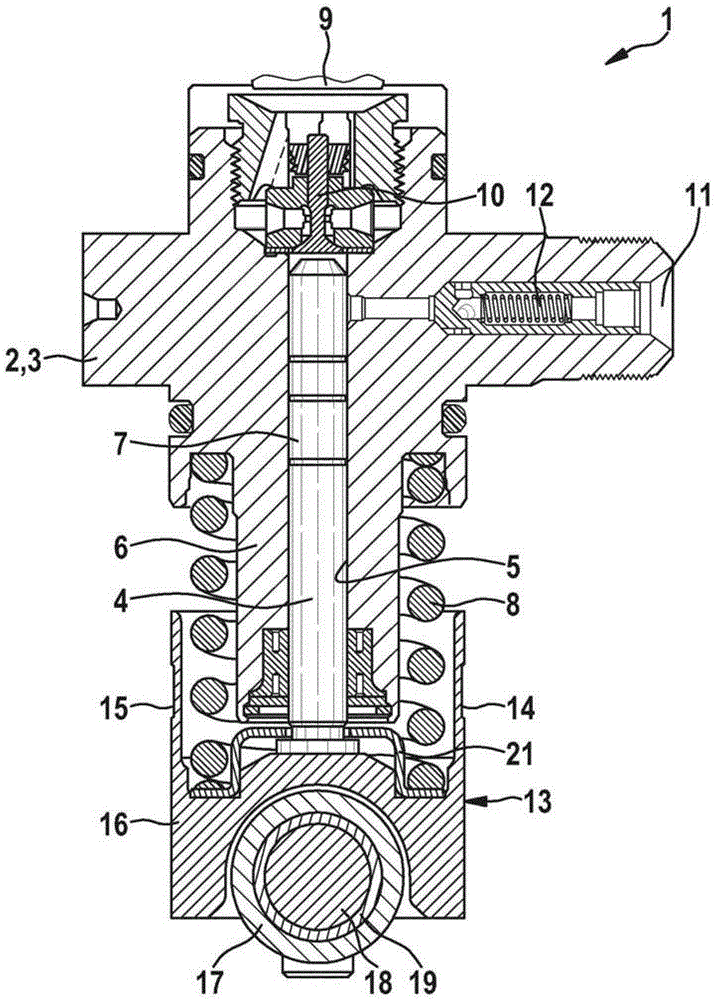

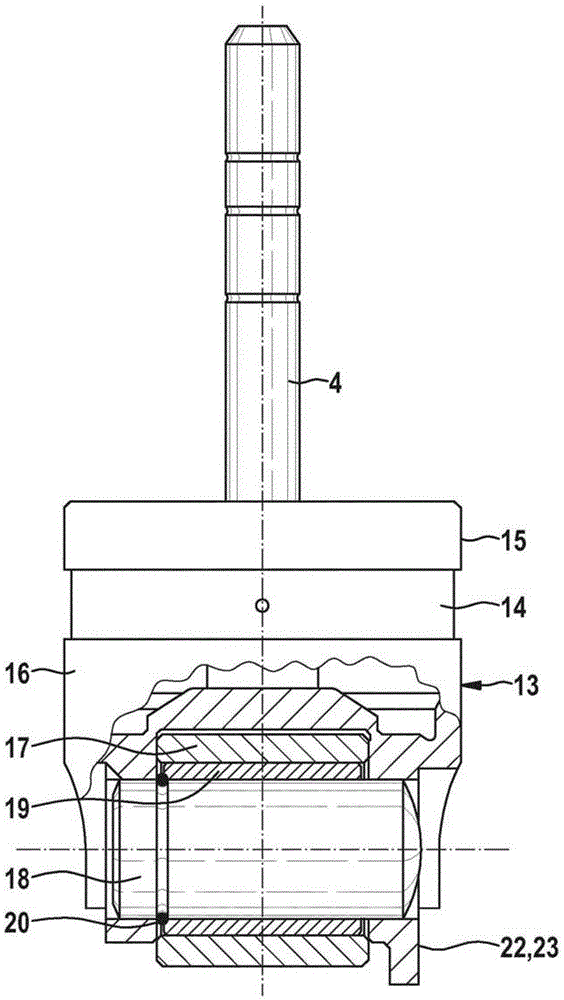

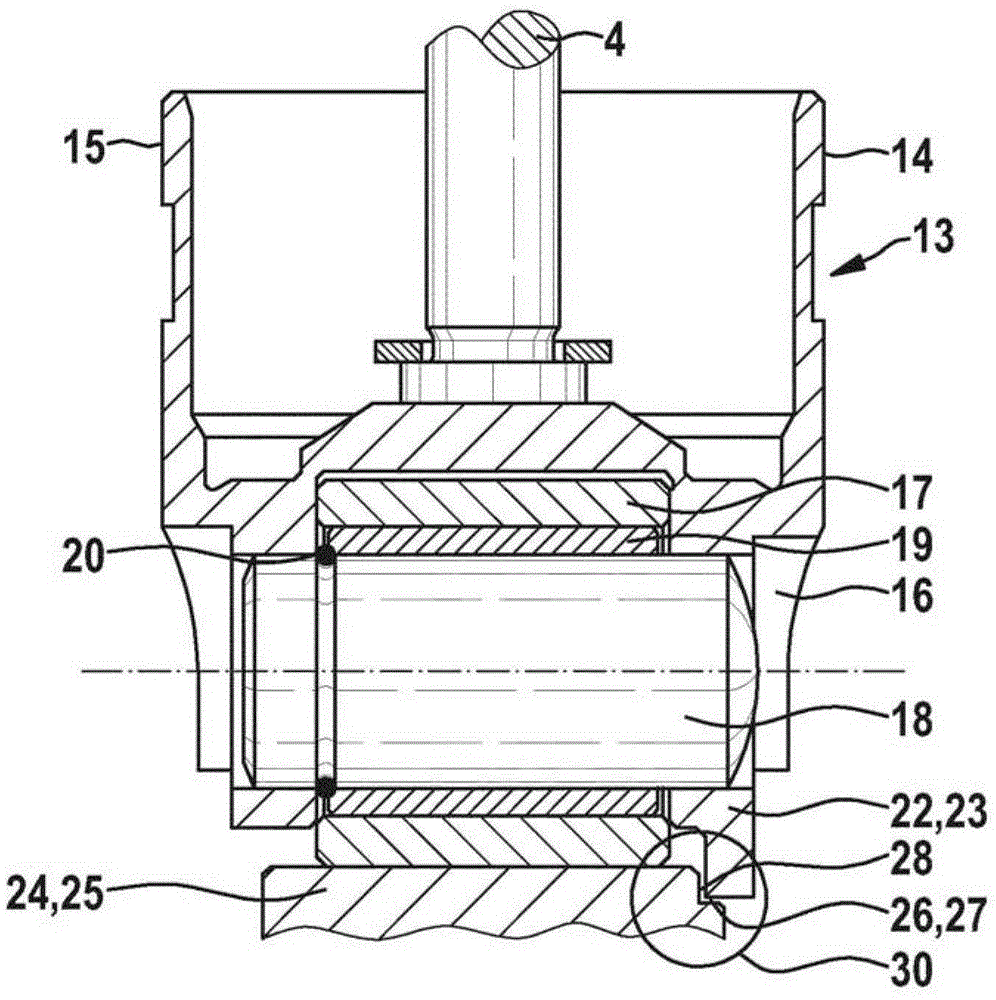

[0023] exist figure 1 A section through a high-pressure pump 1 for a fuel injection system, which is designed as a cartridge pump, is shown in . The high-pressure pump 1 shown here uses a common rail system. The high-pressure pump 1 has a pump housing 2 with a cylinder head 3 in which a pump element with a pump piston 4 is located, which is driven in rotation via a drive shaft (not shown here) ( see image 3 ) is indirectly driven to reciprocate in a direction at least approximately radial with respect to the axis of rotation of the drive shaft. The pump piston 4 is guided sealingly displaceably in the cylinder bore 5 in the section 6 of the cylinder head 3 and delimits a pump working chamber 7 in the cylinder bore 5 with the end face of the pump piston facing away from the drive shaft. A spring 8 is arranged around the circumference of the section 6 .

[0024] The pump working chamber 7 is supplied with fuel via a fuel inlet 9 from a fuel tank of a high-pressure fuel inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com