Hollow slab cavity plugging method

A hollow slab and cavity technology, which is used in the erection/assembly of bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of difficulty in dismantling and rebuilding, waste of resources and high cost, and achieve the effect of improving durability and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

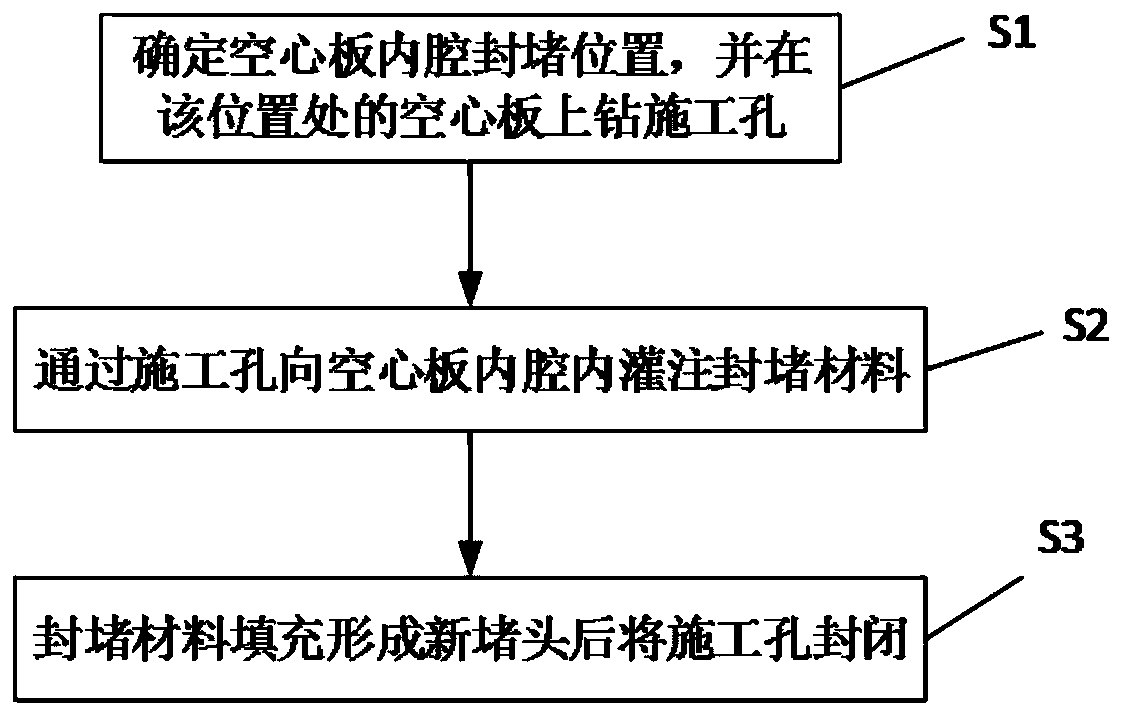

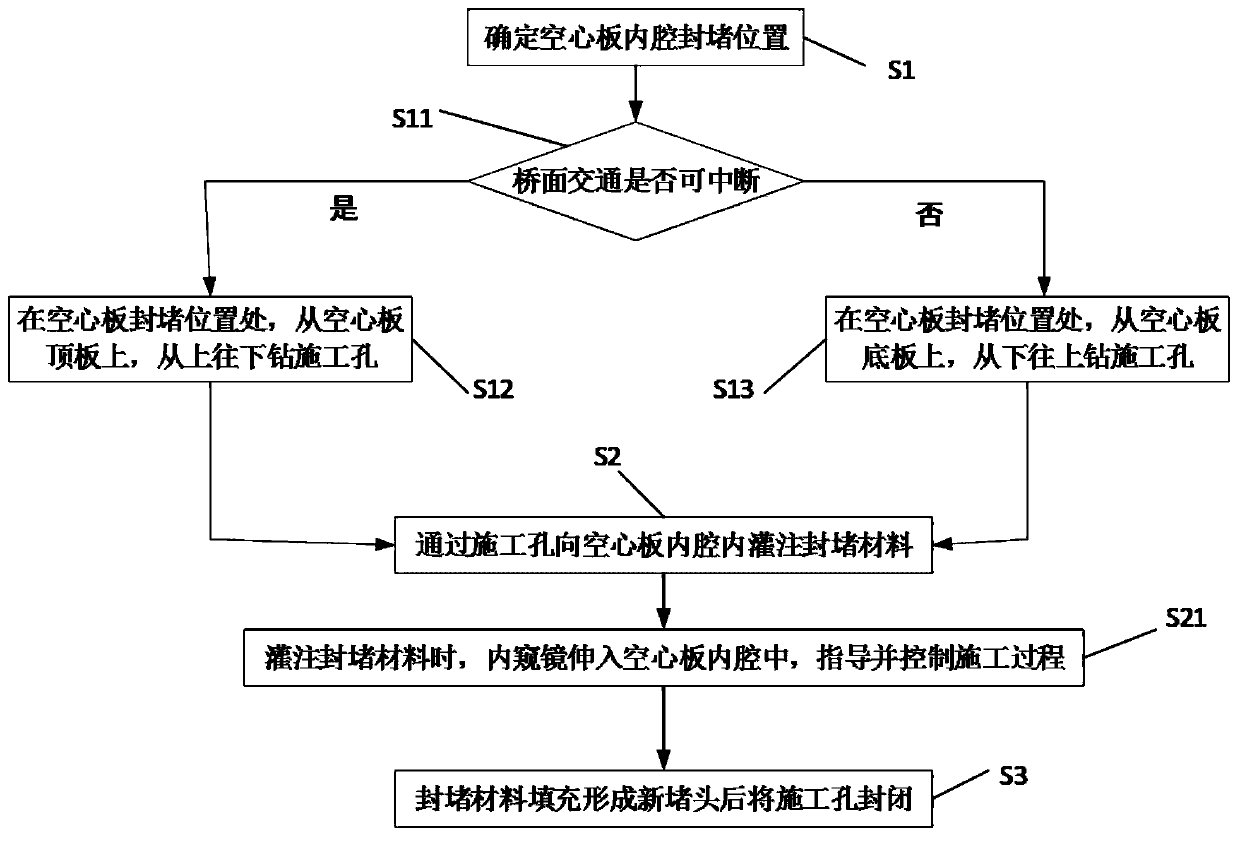

[0063] figure 2 The hollow plate 1 cavity sealing method provided for the embodiment of the present invention, this method can seal or reinforce the hollow plate 1, this method is mainly for the problem of waterproof failure of the old plug, and the situation of resetting the plug , and at the same time, this method specifically specifies whether the traffic on the bridge road is interrupted.

[0064] Such as figure 2 As shown, the cavity sealing method of the hollow plate 1 provided in this embodiment specifically includes the following steps:

[0065] S1: determine the cavity sealing position of the hollow plate 1;

[0066] S11: Determine whether the traffic on the bridge deck can be interrupted, if so, execute step S12, if not, execute step S13;

[0067] S12: Drill a construction hole from the top of the hollow plate 1 from top to bottom at the plugging position of the hollow plate 1;

[0068] S13: Drill construction holes from the bottom of the hollow plate 1 from bo...

Embodiment 2

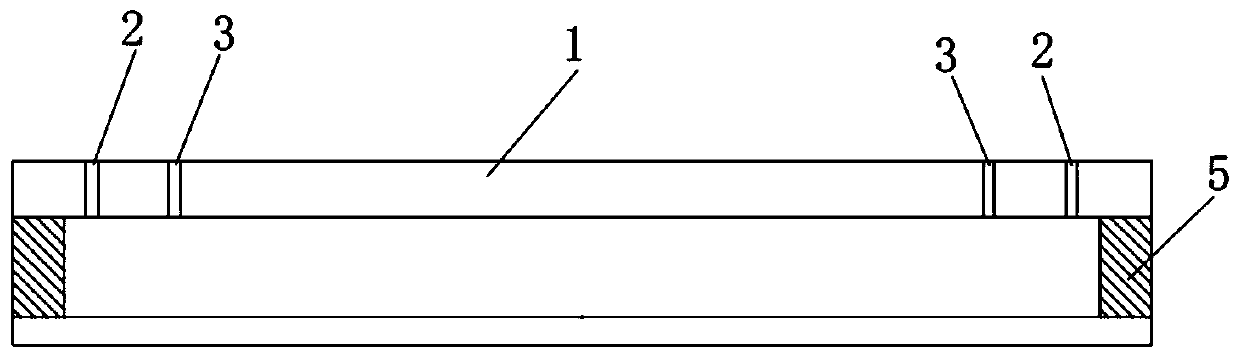

[0078] Figure 15 The schematic flow chart of the method for sealing the cavity of the hollow slab 1 provided by the embodiment of the present invention. This method can seal or reinforce the hollow slab 1. This method is mainly for the local thinning of the bottom plate and the exposed steel strands of the hollow slab 1. It is carried out on defects or diseases such as cavities. Of course, when the section of the cavity of the hollow plate 1 needs to be filled with fluid material for section reinforcement, the section of the cavity of the hollow panel 1 needs to be filled with fluid material for section reinforcement. When it is strong, the function of the new plug 6 is that of a lateral template to control the pouring position of the fluid perfusion material and limit the flow of the perfusion material. At the same time, the method specifically specifies whether the traffic on the bridge road surface is interrupted.

[0079] Such as Figure 15 As shown, the cavity sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com