Underground curved roadway tunneling construction method

A construction method and roadway technology, which are applied in tunnels, earthwork drilling, image data processing, etc., can solve the problems of roadway over- and under-excavation, construction quality problems, low cycle footage, etc., to ensure construction quality, reduce excavation deviation, The effect of mining deviation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

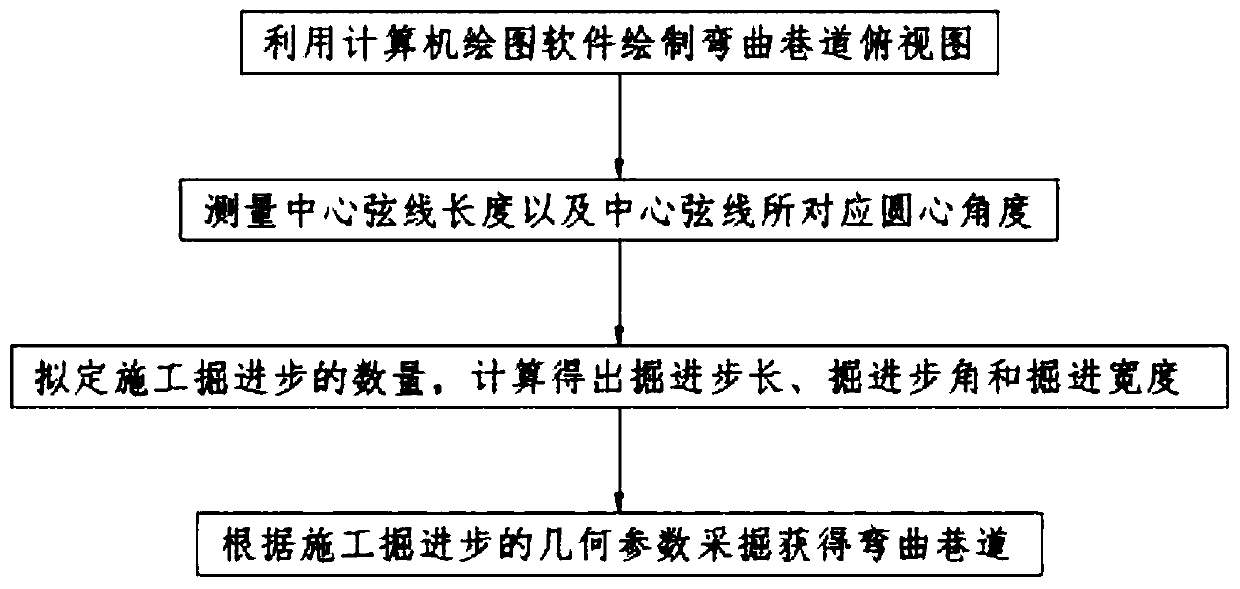

[0025] Such as figure 1 , figure 2 As shown, the invention provides a kind of underground curved roadway excavation construction method comprising the following steps:

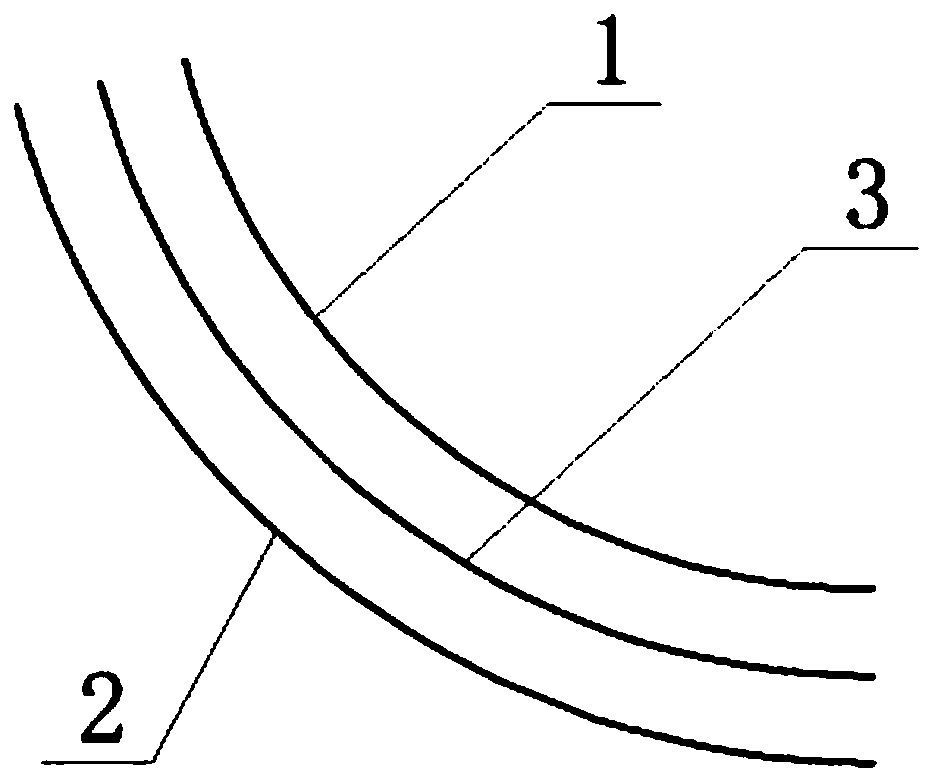

[0026] Step 1: Use a computer installed with corresponding drawing software to draw a top view of the curved roadway to be excavated according to an appropriate scale. The top view of the curved roadway is composed of two parallel curve inner contour lines 1 and curve outer contour lines 2, and then draw A curve center chord line 3 that is equal to the positions of the curve inner contour line 1 and the curve outer contour line 2 is obtained; the preferred scale is 1:100. The preferred drawing software is AutoCAD.

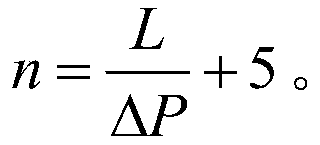

[0027] Step 2: Measure and obtain the length of the center chord in step 1 and the angle of the center of the circle corresponding to the center ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com