Shield tunnel composite waterproof structure

A waterproof structure, shield tunnel technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of reduced waterproof performance of gaskets, no waterproof structure, easy sliding of gaskets, etc., to extend the water seepage flow path, prevent The effect of leakage, good water resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

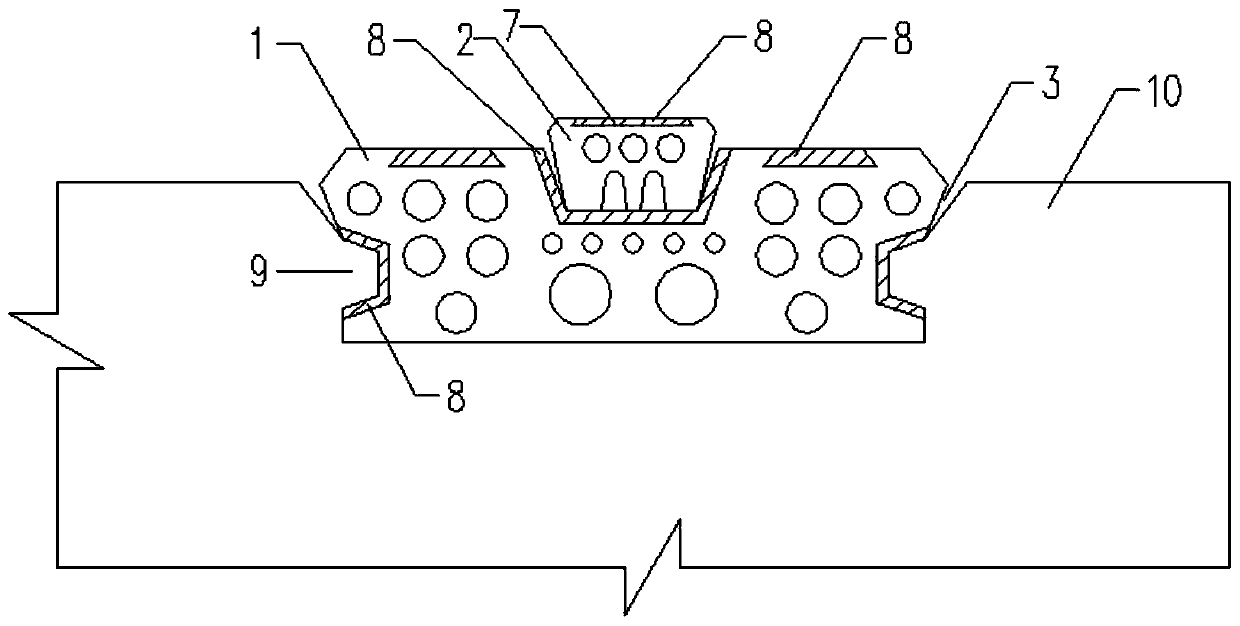

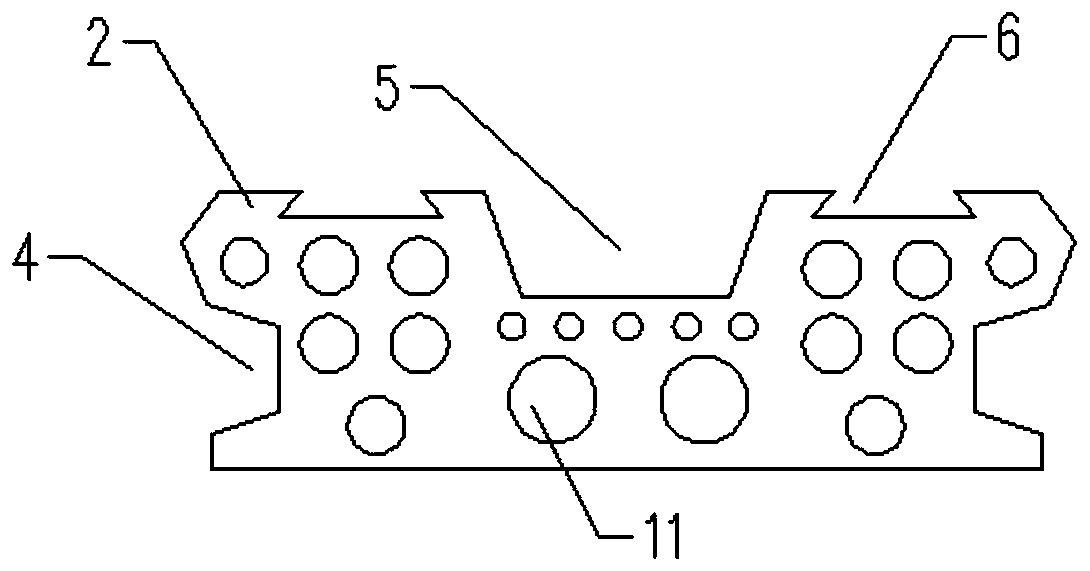

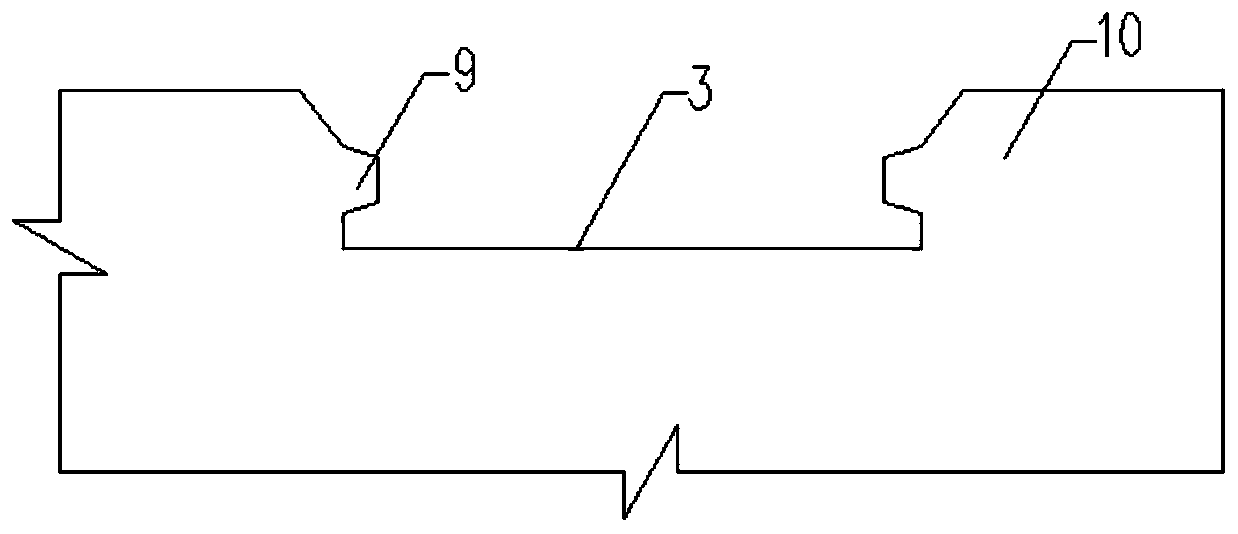

[0028] Such as Figures 1 to 3 As shown, a composite waterproof structure of a shield tunnel, including a waterproof gasket and a shield segment gasket groove 3, the waterproof gasket includes a gasket body 1, and the gasket body 1 is a left-right symmetrical structure, which is evenly stressed and sealed. The main body of the gasket 1 is set in the groove 3 of the shield segment gasket. There is a first groove 4 on each side of the left and right sides of the gasket body 1, and the two first grooves 4 are arranged symmetrically. The shield segment is sealed The gasket groove 3 is provided with a protrusion 9 corresponding to the first groove 4, and the top of the gasket main body 1 is provided with a second groove 5, and the gasket auxiliary body 2 is arranged in the second groove 5, and the gasket auxiliary The body 2 can adopt the existing technology. The top of the gasket auxiliary body 2 is provided with a fourth groove 7, and the water-swellable rubber 8 is embedded in t...

Embodiment 2

[0030] Such as Figure 4 with 5As shown, a composite waterproof structure of a shield tunnel, including a waterproof gasket and a shield segment gasket groove 3, the waterproof gasket includes a gasket body 1, and the gasket body 1 is a left-right symmetrical structure, which is evenly stressed and sealed. The main body of the gasket 1 is set in the groove 3 of the shield segment gasket. There is a first groove 4 on each side of the left and right sides of the gasket body 1, and the two first grooves 4 are arranged symmetrically. The shield segment is sealed The gasket groove 3 is provided with a protrusion 9 corresponding to the first groove 4, and the top of the gasket main body 1 is provided with two second grooves 5, and the two second grooves 5 are arranged symmetrically, and each second groove 5 are respectively provided with sealing gasket auxiliary body 2, two sealing gasket auxiliary bodies 2, which greatly improve the waterproof performance of the middle part, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com