Scroll compressor, air conditioner and vehicle

A technology of scroll compressors and static scrolls, applied in machines/engines, rotary piston machinery, mechanical equipment, etc., can solve exhaust pipeline vibration, exhaust end cover violent vibration, abnormal compressor noise, etc. problem, achieve the effect of reducing noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

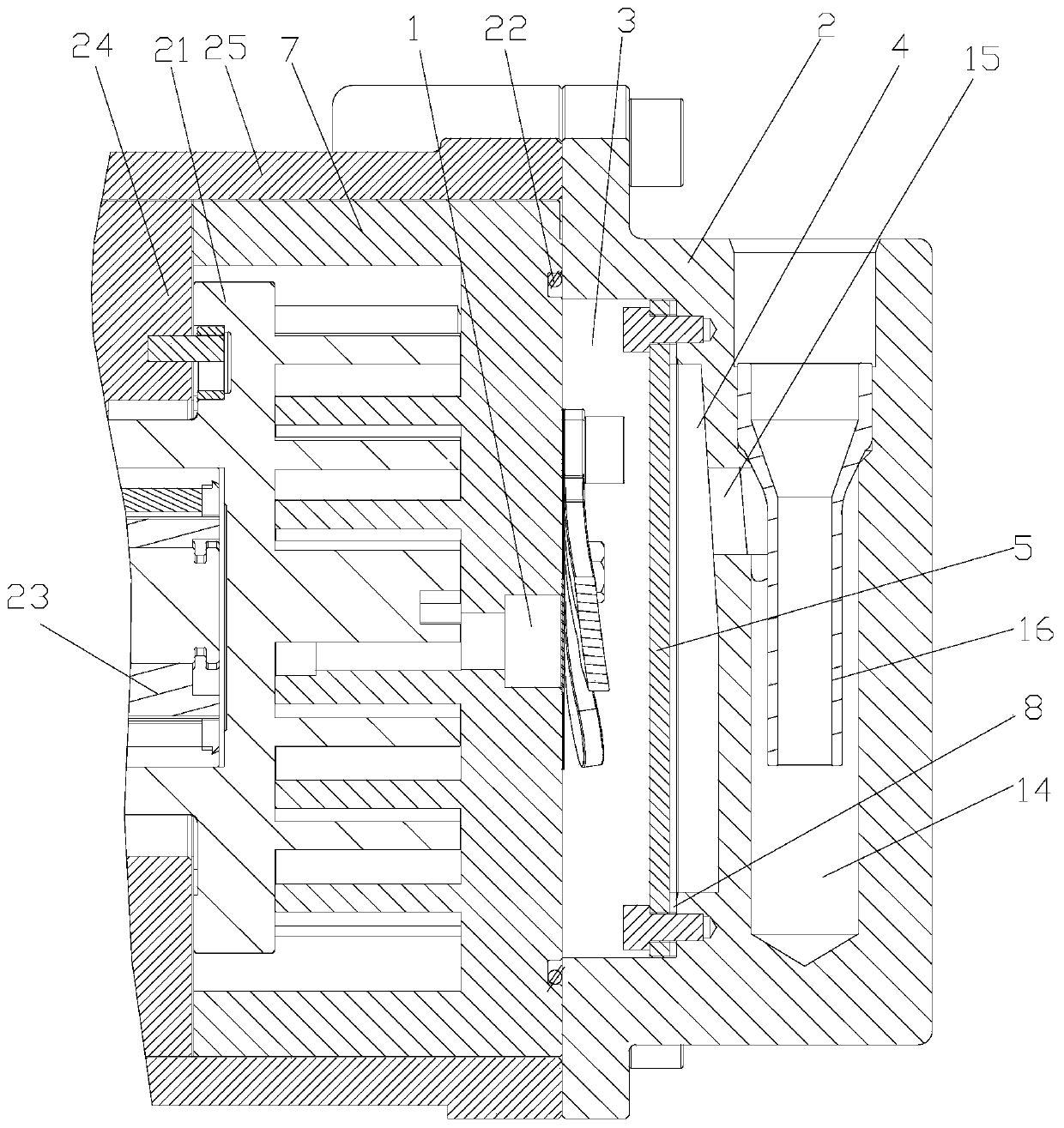

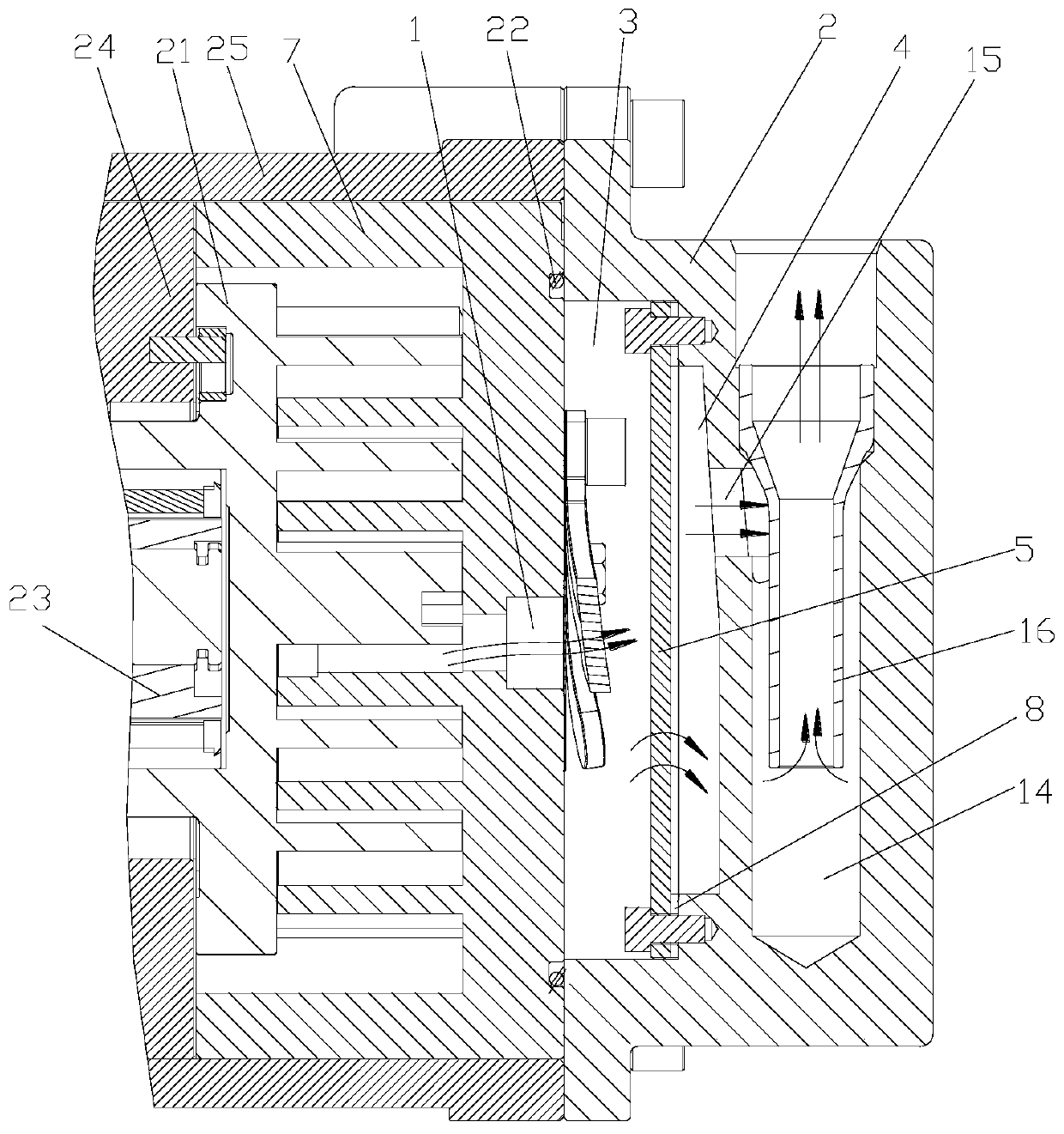

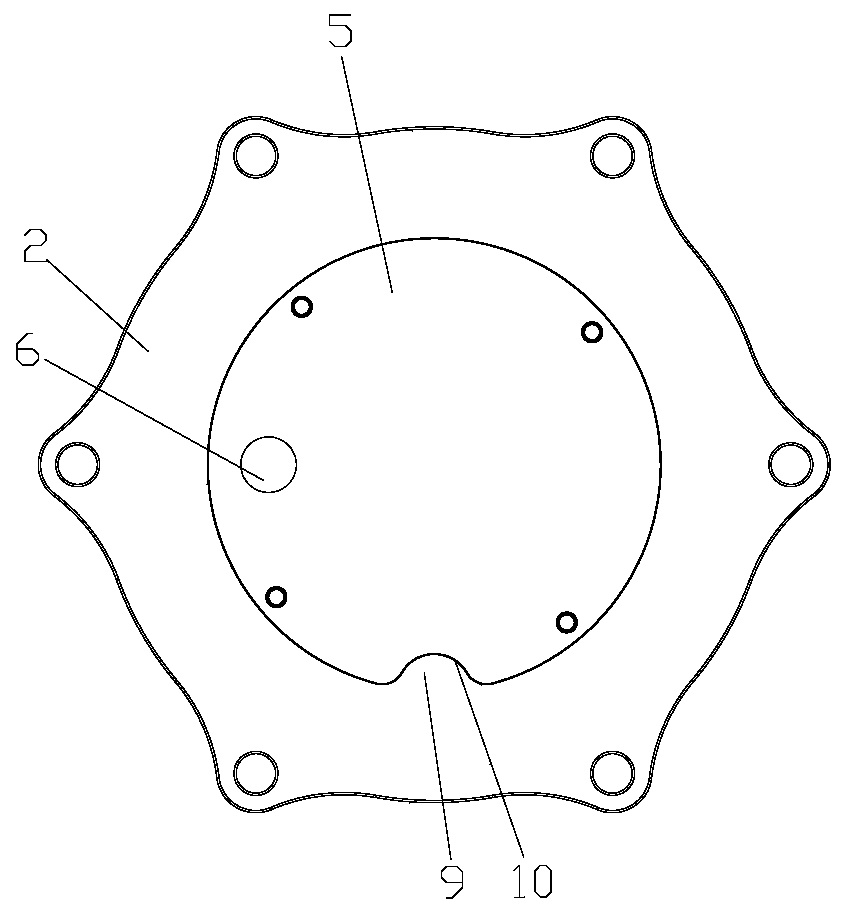

[0038] see in conjunction Figure 1 to Figure 10 As shown, according to the embodiment of the present application, the scroll compressor includes an exhaust port 1 and an exhaust upper cover 2 covered at the exhaust port 1. The exhaust upper cover 2 includes a cavity, and an exhaust gas is arranged in the cavity. Noise-absorbing structure, the exhaust-muffling structure divides the cavity into a first exhaust chamber 3 and a second exhaust chamber 4, the first exhaust chamber 3 communicates with the exhaust port 1, and the second exhaust chamber 4 is located in the row The gas sound-absorbing structure is on the side away from the exhaust port 1 , and the gas discharged from the exhaust port 1 enters the second exhaust chamber 4 after passing through the first exhaust chamber 3 .

[0039] The first exhaust cavity 3 and the second exhaust cavity 4 can be formed by setting the exhaust noise reduction structure between the compressor exhaust port 1 and the exhaust upper cover 2, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap