Calibration method and device of optical fiber strain sensing system

A technology of optical fiber strain and sensing system, which is applied in measurement devices, electrical devices, instruments, etc., to ensure rationality and feasibility, improve accuracy, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

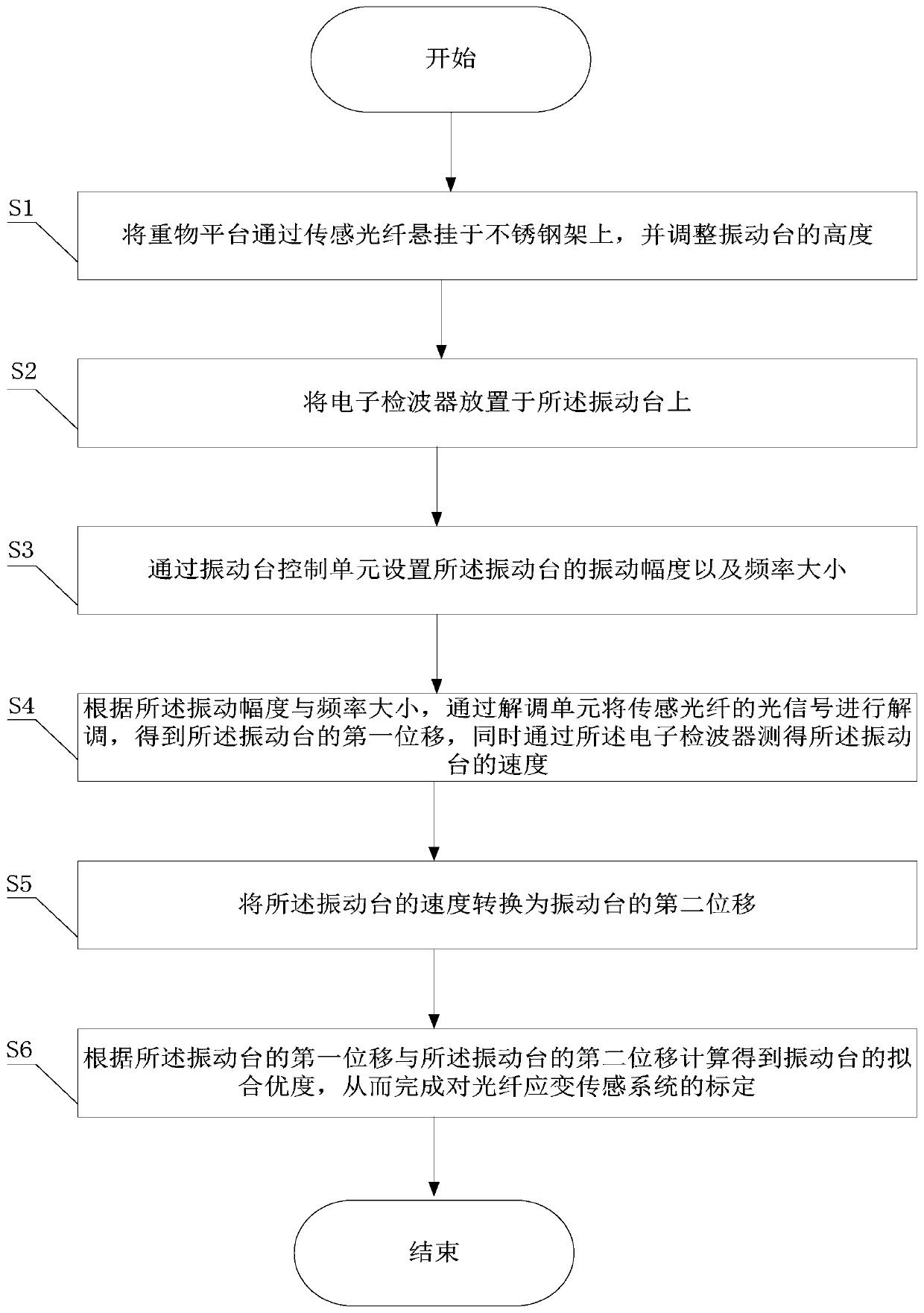

[0058] Such as figure 1 As shown, a calibration method of an optical fiber strain sensing system is implemented as follows:

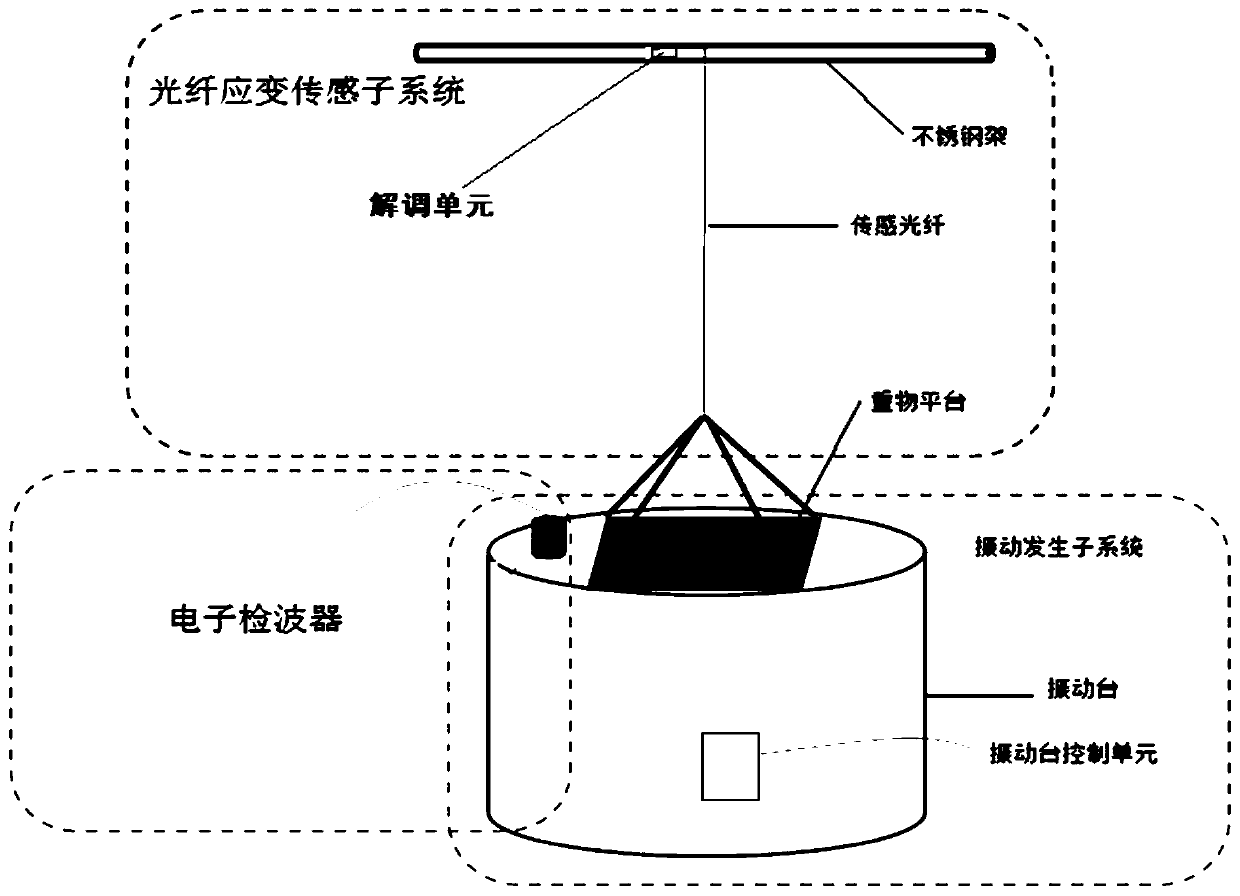

[0059] S1. Suspend the heavy object platform on the stainless steel frame through the sensing optical fiber, and adjust the height of the vibration table, wherein the stainless steel frame is at least 2 meters in height, and it is fixed on the ground. The length of the sensing optical fiber At least 20 meters, and it is wound at least 10 turns between the heavy object platform and the stainless steel frame, the weight of the heavy object platform is greater than 4kg, when the heavy object platform is lifted by the sensing optical fiber, the weight The bottom surface of the object platform is kept level with the vibrating table, and the sensing optical fiber is kept in a tight state;

[0060] S2. Place the electronic detector on the vibration table, wherein the electronic detector is a PS-10R speed type electronic detector;

[0061] S3. Setting the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com