Method for manufacturing liquid crystal panel

A technology for liquid crystal panels and manufacturing methods, applied in the fields of nonlinear optics, instruments, optics, etc., which can solve the problems of cutting margin liquid crystal panel miniaturization obstacles, difficulty in using the first glass substrate and the second glass substrate, etc., and achieve reduction Effect of stock removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

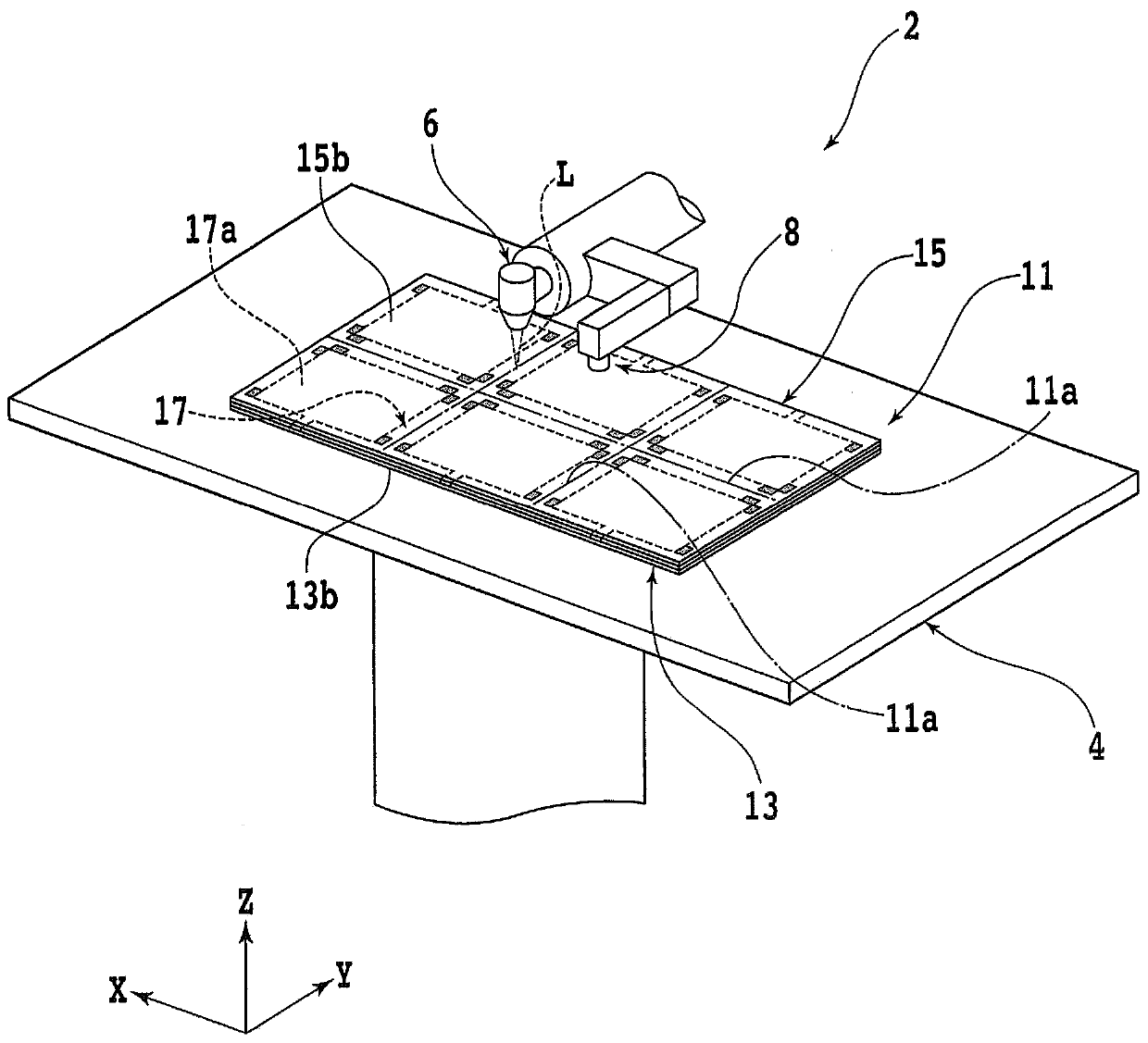

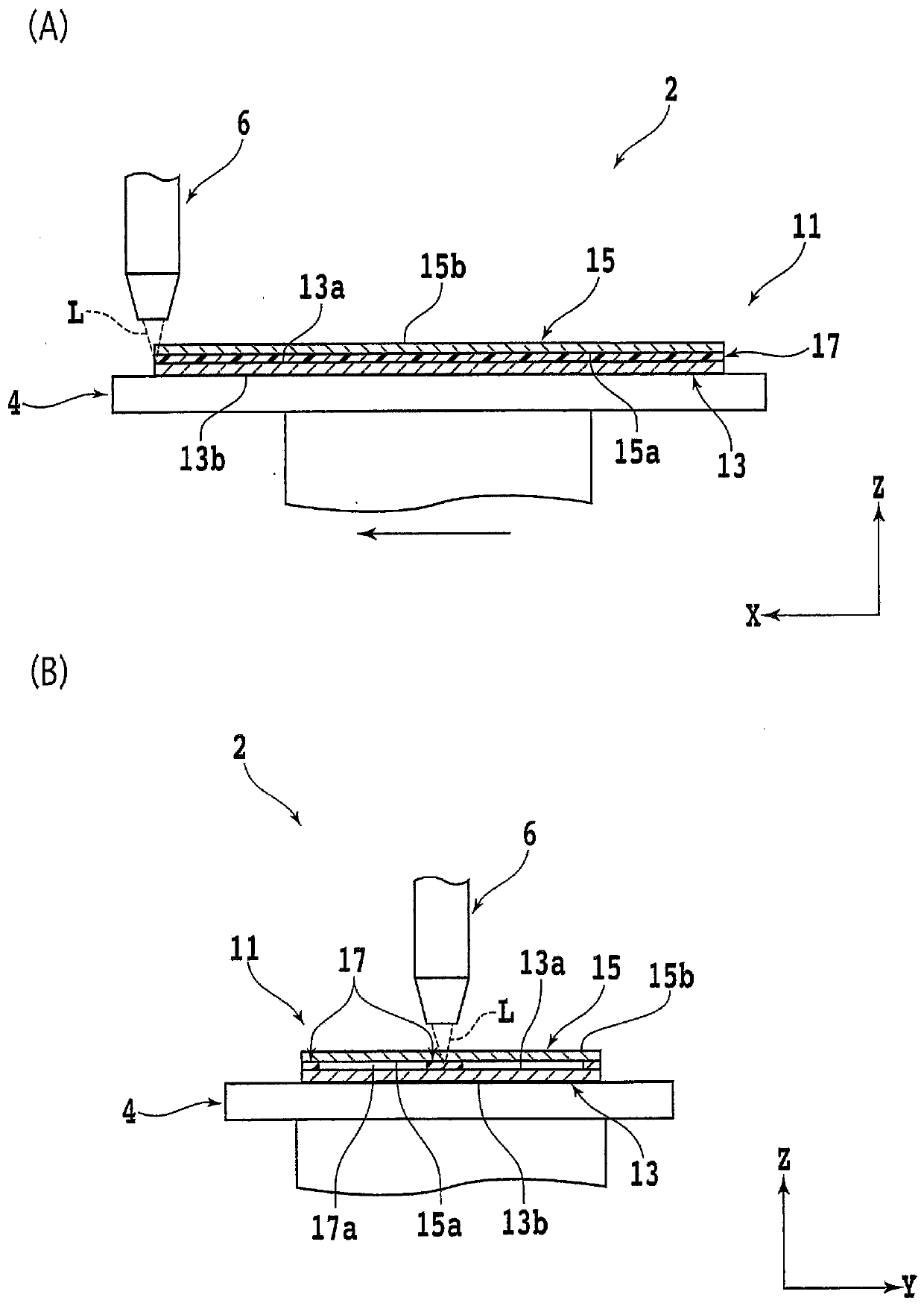

[0019] An embodiment of one embodiment of the present invention will be described with reference to the drawings. The manufacturing method of the liquid crystal panel of this embodiment comprises a laser processing step (refer to figure 2 , image 3 of (A), image 3 of (B), Figure 4 (A) and Figure 4 (B)) and segmentation steps (see Figure 5 ).

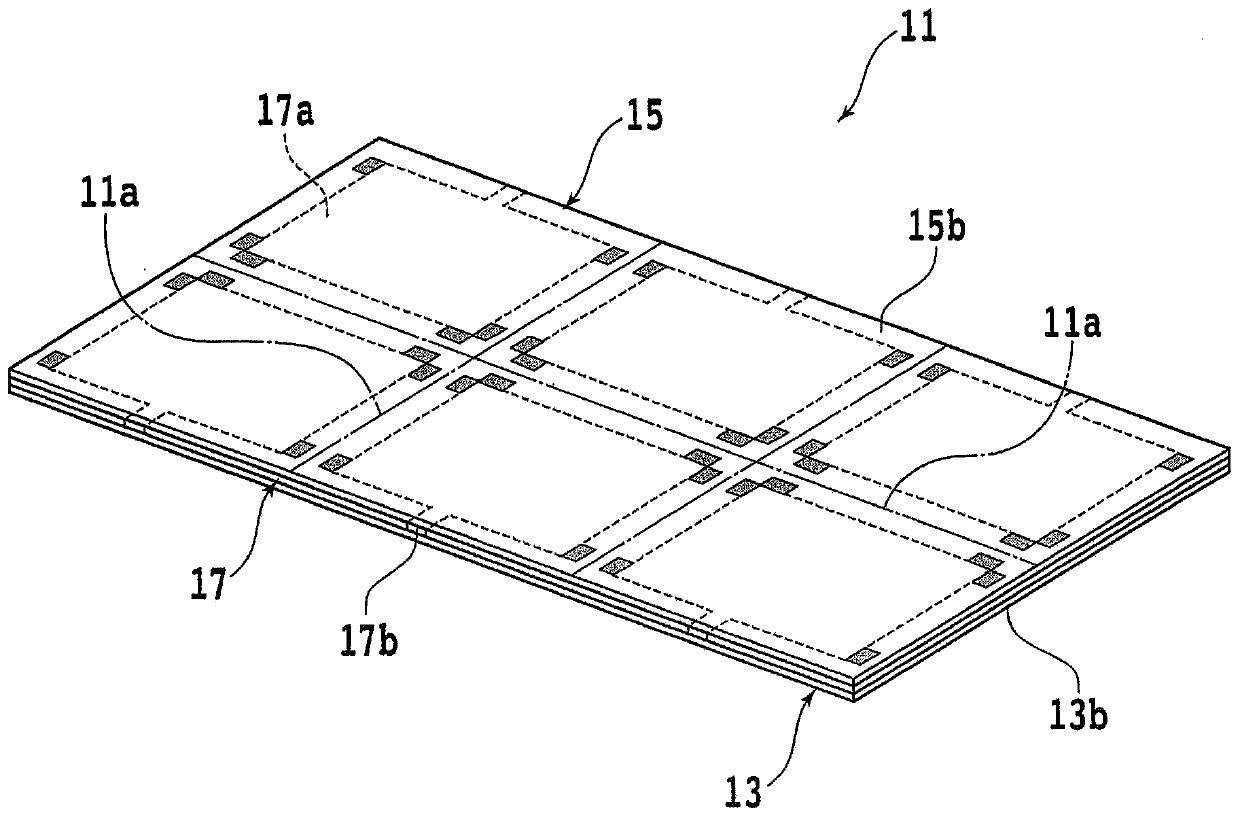

[0020] In the laser processing step, the laser beam of the wavelength transmitted through the glass substrate is condensed inside the bonded substrate to form a shield tunnel including fine holes and modified parts surrounding the fine holes in the bonded substrate. It has: a sealing tape that defines a liquid crystal chamber; and two glass substrates that are bonded together through the sealing tape. In the dividing step, the bonded substrate is divided into a plurality of liquid crystal panels along the shield tunnel formed on the bonded substrate. Hereinafter, the manufacturing method of the liquid crystal panel of this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com