A processing tool and processing method for inner hole tooth groove of steam seal ring

A technology for machining tools and steam seal rings, which is applied to tools for lathes, manufacturing tools, metal processing equipment, etc., can solve the problems of workpiece loss, high resistance, and easy breakage of tool heads, and save processing costs. , easy to use, reduce the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

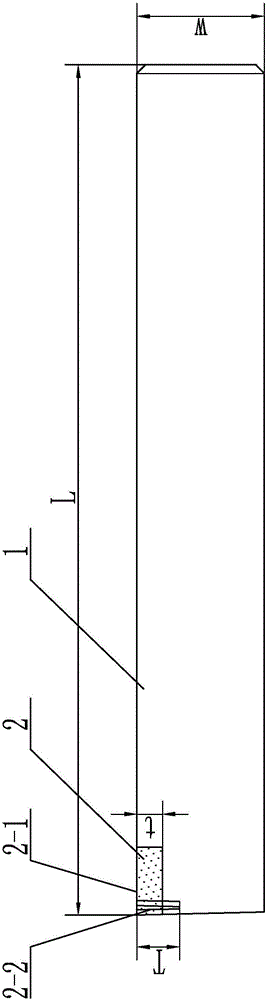

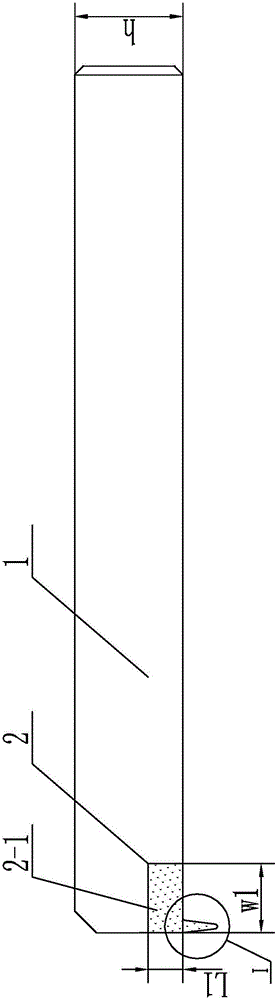

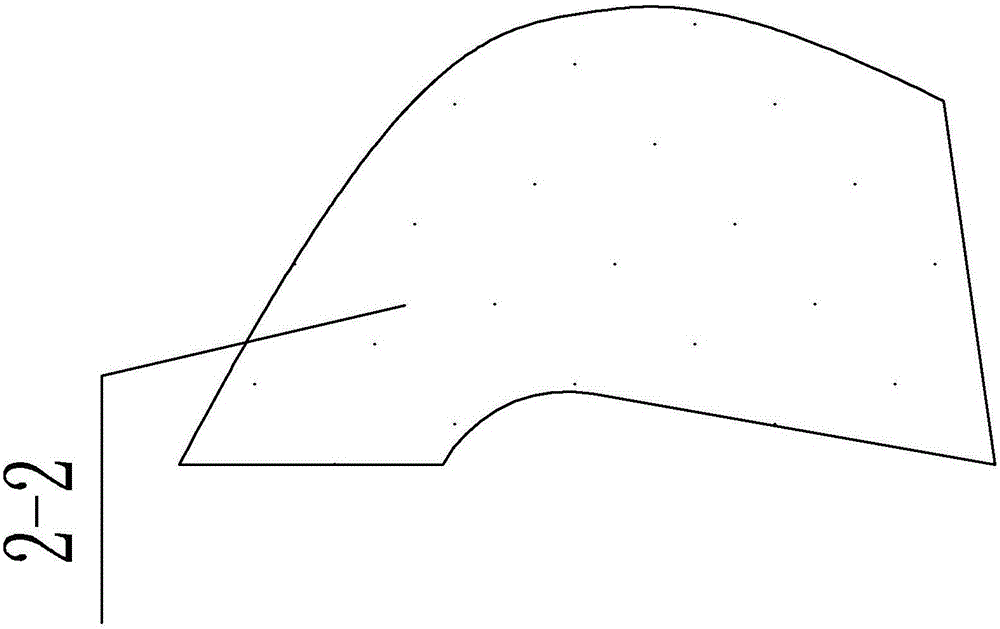

[0015] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, the processing tool used for the tooth groove of the inner hole of the steam seal ring described in this embodiment, the tool includes a handle 1 and a head 2, the handle 1 is a cuboid, and the head 2 includes a press The tight block 2-1 and the cutting edge 2-2, the pressing block 2-1 is a cuboid, one end of the handle 1 is processed with a rectangular notch, and the cutting edge 2-2 is fixed on the handle through the pressing block 2-1 1. In the rectangular gap, the cutting edge portion 2-2 is perpendicular to the handle 2-1, and the cutting edge portion 2-2 is located on one side of the handle 1.

specific Embodiment approach 2

[0016] Specific implementation mode two: combination image 3 and Figure 4 Describe this embodiment, a kind of processing tool used for the tooth groove of the inner hole of the steam seal ring described in this embodiment, the rake angle of the cutting edge part 2-2 is 6°, and the rear angle of the cutting edge part 2-2 is 8°, the secondary rake angle of the cutting edge portion 2-2 is 1°30′, the secondary relief angle of the cutting edge portion 2-2 is 1°30′, and the others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 , figure 2 and Figure 5 Describe this embodiment, a kind of machining tool used for the tooth groove of the inner hole of the steam seal ring described in this embodiment, the length of the handle 1 is L, the value of L is 300mm, and the width of the handle 1 is w, w The numerical value of is 30mm, and the height of handle of a knife 1 is h, and the numerical value of h is 25mm, and other is identical with specific embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com