Paperless tracing method for automobile parts

A technology for auto parts and parts, applied in the field of paperless traceability of auto parts, can solve the problems of increasing the difficulty of reading and querying, low efficiency, large manual workload, etc., to achieve a simple, convenient and reliable traceability method, and reduce human factors and risks. Low coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

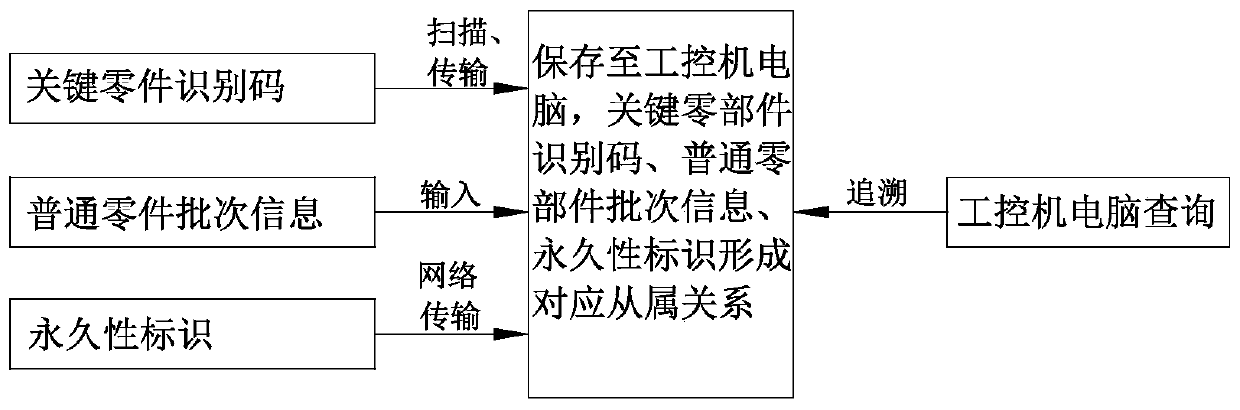

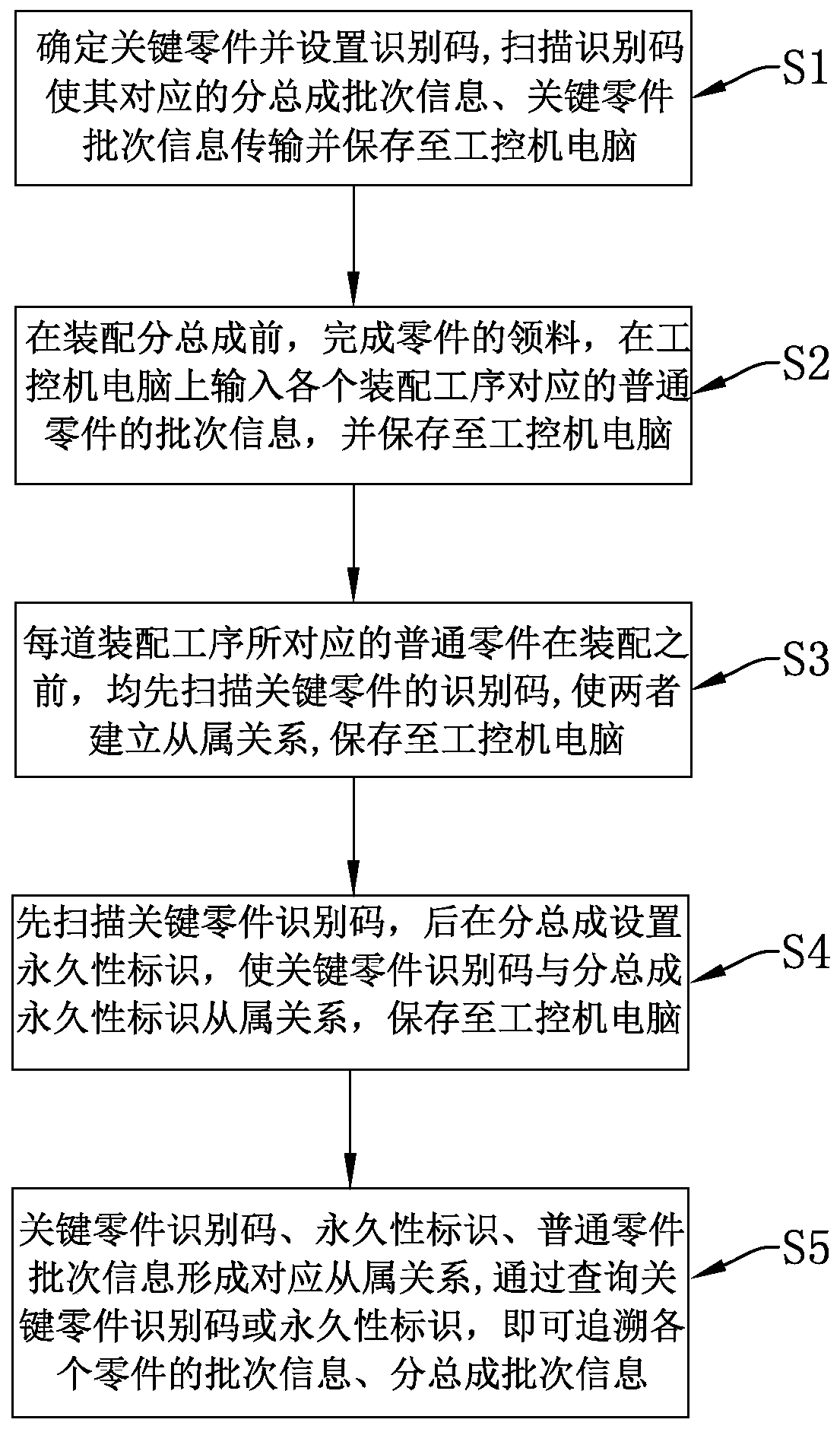

[0033] A paperless traceability method for auto parts, including an industrial computer computer, each assembly station is equipped with a code scanning gun connected to the computer network of the industrial computer; the parts of the automobile sub-assembly include key parts and common parts, of which the key The part is the exposed one of the sub-assembly parts, and the rest are common parts; the specific steps are as follows:

[0034] S1: Set up identification codes on key parts, specifically barcodes, and scan the identification codes so that the corresponding sub-assembly batch information and key part batch information are transmitted and saved to the computer of the industrial computer;

[0035] S2: Before assembling the sub-assembly, complete the picking of parts, input the batch information of the common parts to be assembled corresponding to each assembly process on the computer of the industrial computer, and save it in the computer of the industrial computer;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com