Piercing electrical connector

An electrical connector and piercing technology, which is applied in the field of piercing electrical connectors, can solve the problems of unreasonable connector structure design, increased connector packaging cost, electrical accidents in electrical appliances, etc., so as to reduce assembly costs and improve Production efficiency, easy packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

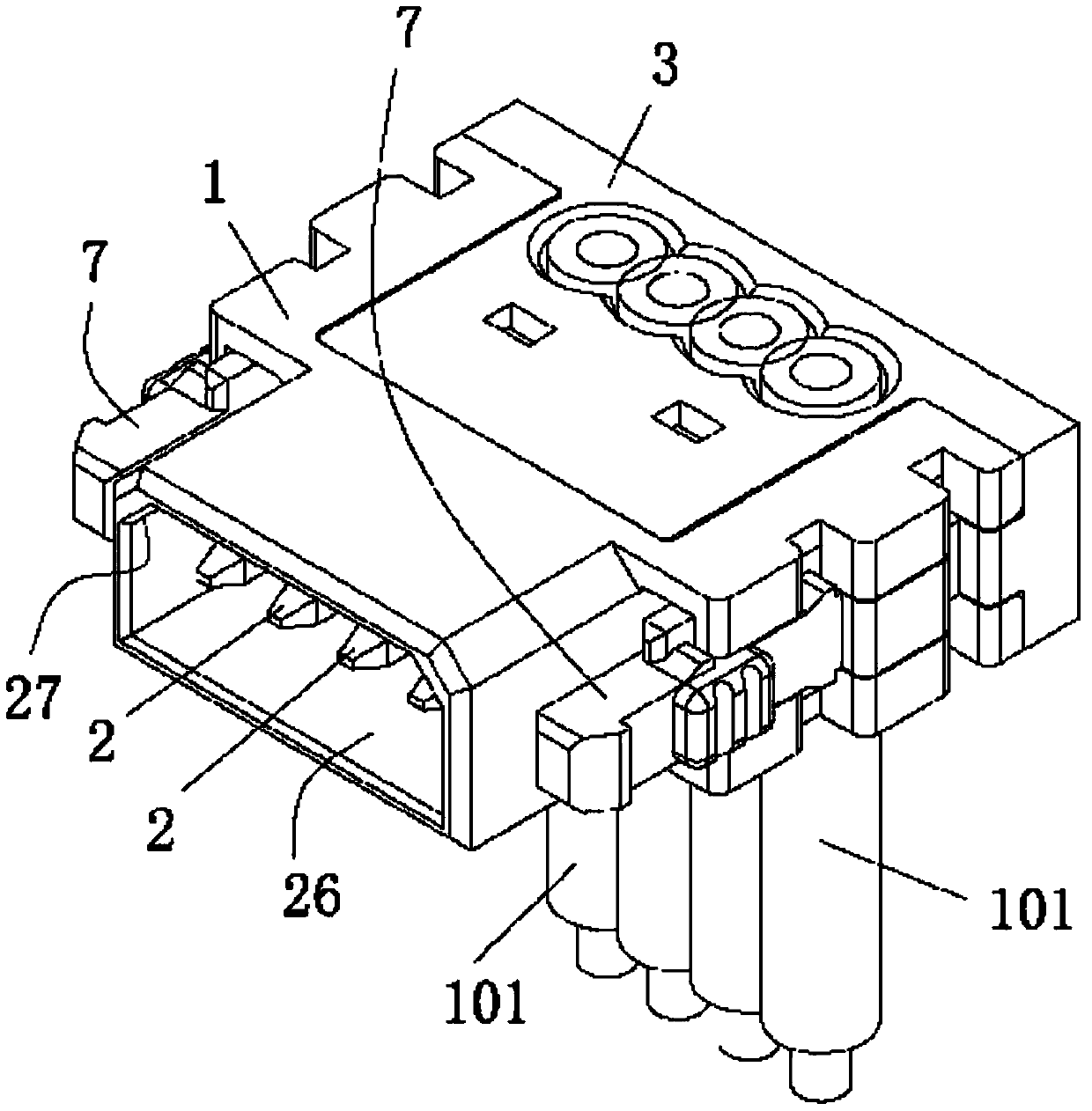

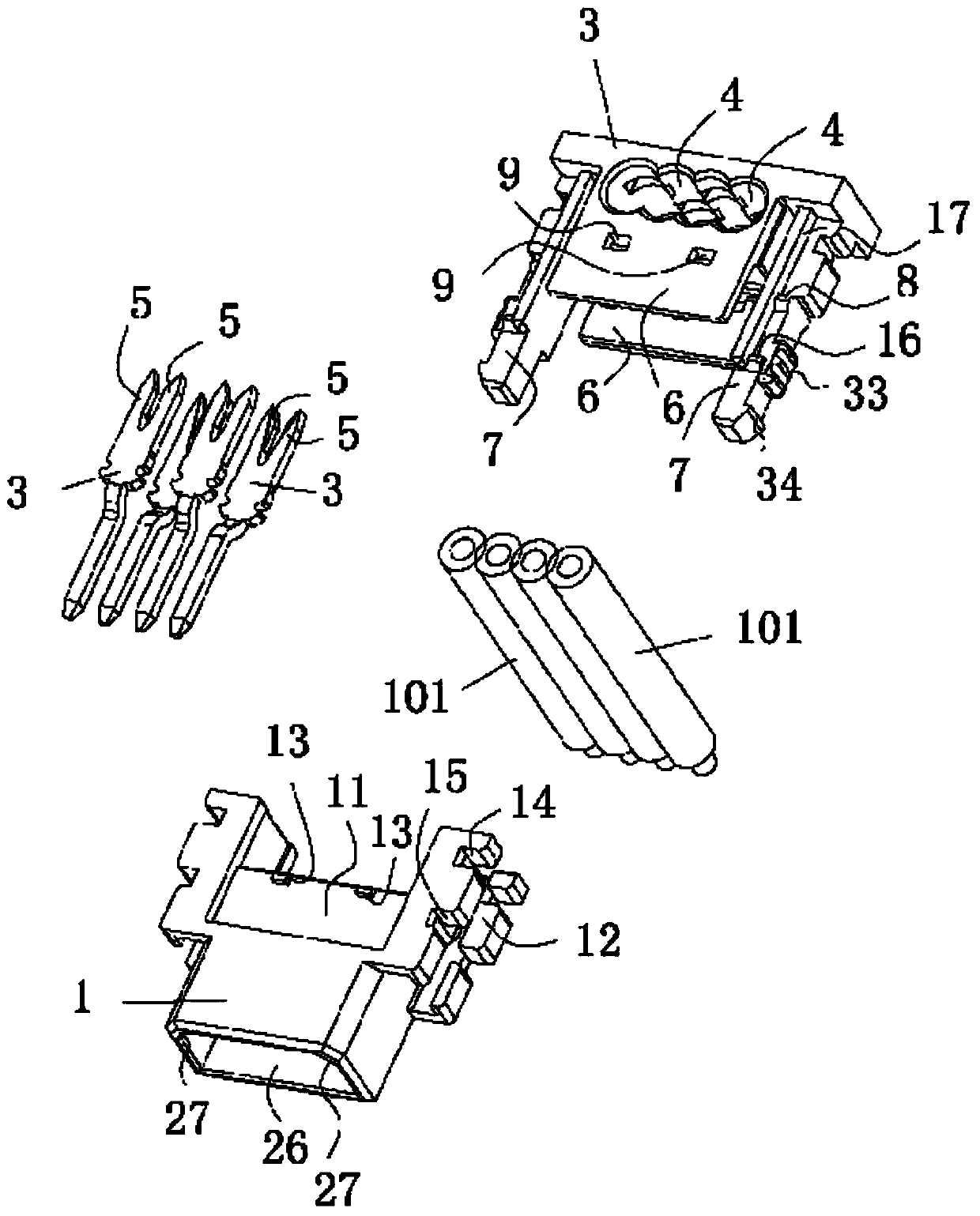

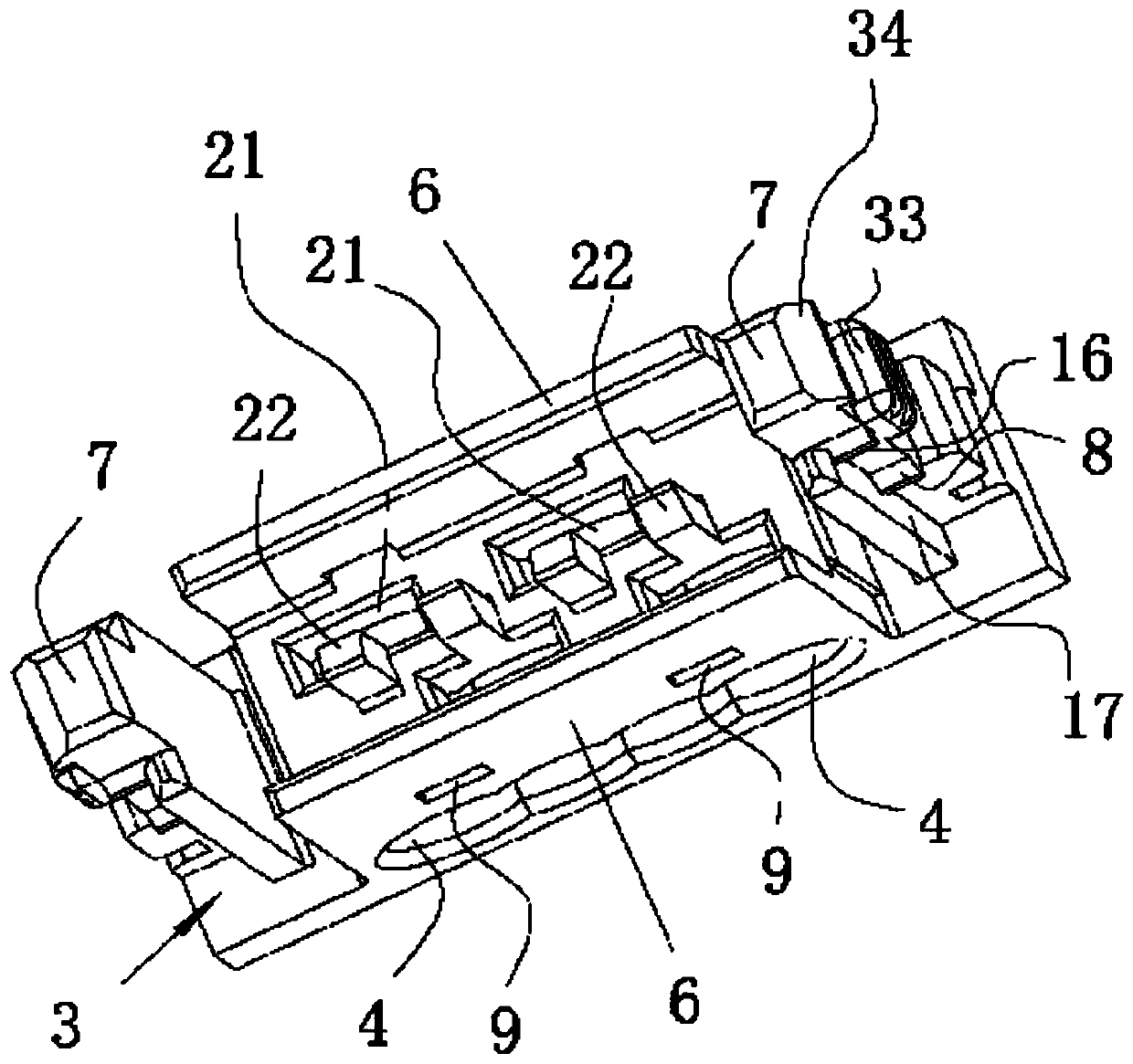

[0045] see Figure 1 to Figure 5 As shown, a piercing type electrical connector of the present invention includes a wire end connector, and the wire end connector has a wire end body 1, a wire end terminal 2 arranged on the wire end body 1, and a snap fit with the wire end body 1 The wire cover 3, the wire end body 1 and the wire cover 3 are all made of insulating plastic. According to the actual needs, the cable 101 can be inserted into the cable or scattered wires, for example, the cable 101 can be commonly used AWG22, AWG24, or AWG26, etc., adjust the aperture of the wire hole 4 for different wire numbers Size is fine. Preferably, the wire holding hole 4 runs through the wire cover 3 , so that after the cable 101 is installed in the wire holding hole 4 , the user can easily see whether the cable 101 is installed in an accurate position. The wire end terminal 2 has a piercing portion 5, and the piercing portion 5 is used to pierce the insulation layer of the cable 101 cont...

no. 2 example

[0083] see Figure 9 As shown, in this embodiment, the board end connector is installed horizontally, and the board end connector includes an insulating body 45, a conductive terminal 46 installed on the insulating body 45, and two reinforcing solder joints installed on the left and right sides of the insulating body 45. Sheet 47. The structure of the insulating body 45 is substantially the same as that of the board end body 28 , and the structure of the conductive terminal 46 is substantially the same as that of the board end terminal 29 , which will not be repeated here. The reinforcing solder leg 41 has the same structure as the reinforcing solder piece 47 .

[0084] The insulating body 45 has a tongue plate 48 protruding from the middle of the front end of the insulating body 45. The tongue plate 48 is parallel to the external circuit board 102. The conductive terminal 46 has a soldering plate portion 49 and an elastic conductive portion 51. The soldering plate portion 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com