Rubber extrusion device and rubber extruded object manufacturing method

A technology of an extrusion device and a manufacturing method, which is applied in the field of rubber extrusion device and rubber extrudate manufacturing, can solve problems such as deviation of extrusion conditions, inability to obtain rubber extrudate, etc., and achieve the effect of suppressing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

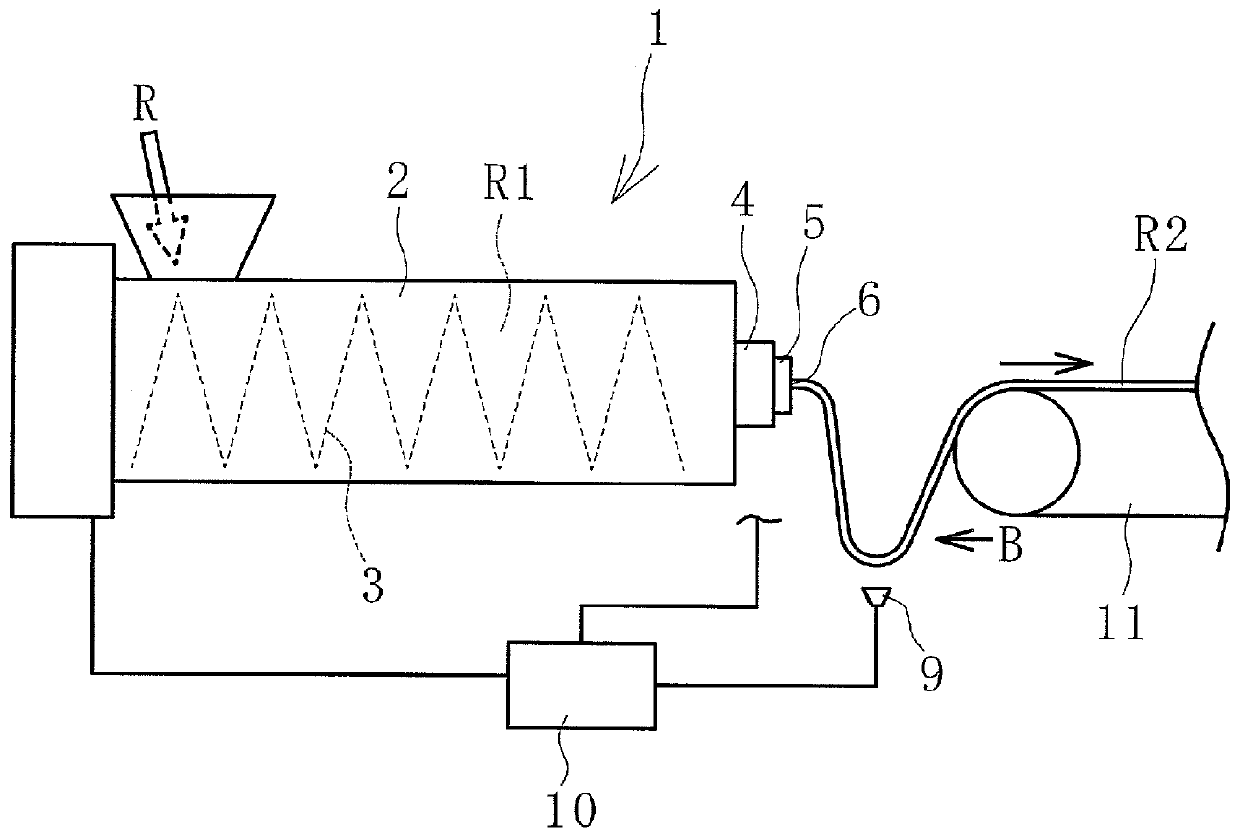

[0026] Hereinafter, the rubber extrusion apparatus and the manufacturing method of the rubber extrudate of the present invention will be described based on the embodiments shown in the drawings.

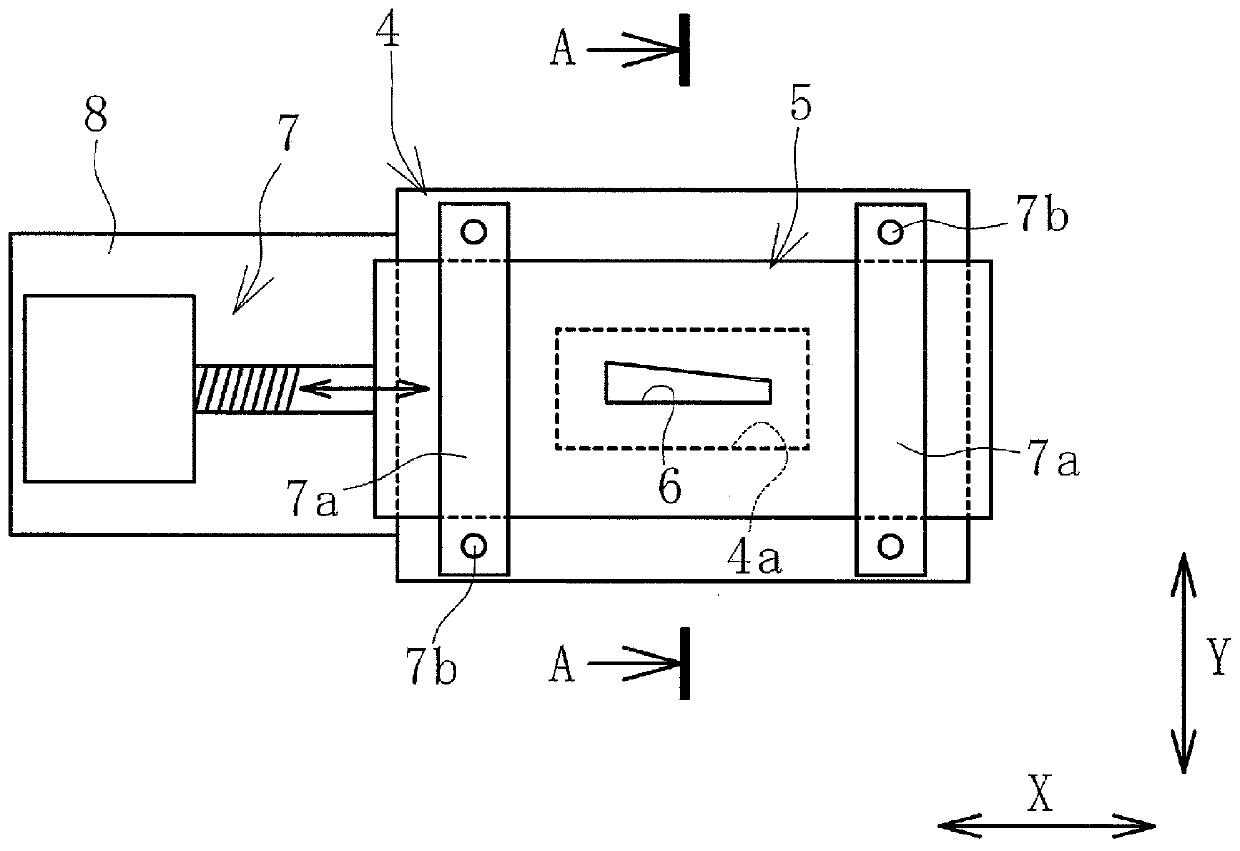

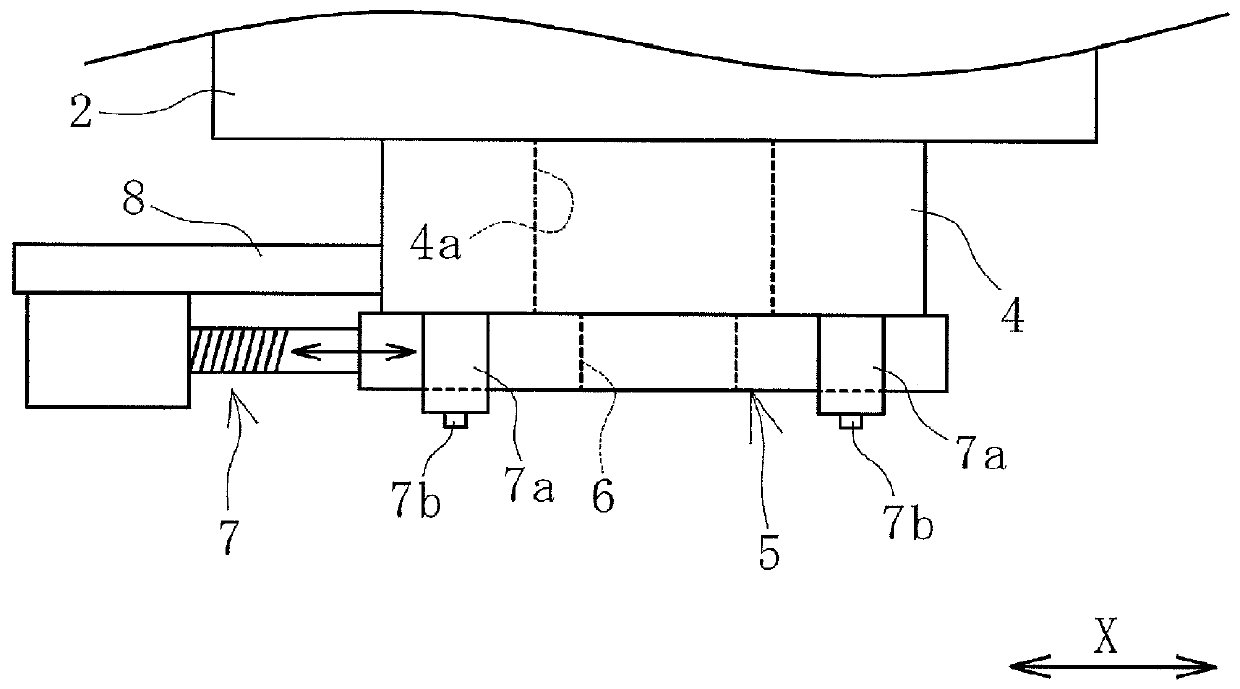

[0027] Figure 1 to Figure 4 The illustrated rubber extrusion apparatus 1 of the present invention includes a cylindrical cylinder 2 , a screw 3 disposed inside the cylinder 2 , a head 4 disposed at the tip of the cylinder 2 , and a controller 10 that controls the rotational speed of the screw 3 . A die head 5 having an extrusion port 6 is attached to the head 4 .

[0028] The rubber extrusion apparatus 1 includes a moving unit 7 and a sensor 9 that relatively move the die head 5 relative to the head 4 in at least one axial direction along the front end surface of the head 4 . The detection data detected by the sensor 9 is input to the control unit 10 , and the operation of the moving unit 7 is controlled by the control unit 10 . Furthermore, in figure 1 In the figure, the moving ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap