Sorting method for reducing defective proportion of luminance inconsistence of solar cell module

A technology of solar cells and cells, which is applied in sorting and other directions, can solve problems such as bad light and dark chips, and achieve the effects of improving module production yield and module output power, reducing defective ratios, and concentrating open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A sorting method for reducing the bad ratio of light and dark sheets of solar cell modules, firstly performing rough classification D of conversion efficiency, including the following specific steps:

[0034] D1: Measure the battery conversion efficiency value of each battery piece in the battery piece group to be tested, and obtain the battery conversion efficiency value interval composed of the battery conversion efficiency value of each battery piece and the battery conversion efficiency values of all battery pieces;

[0035] D2: Set the battery conversion efficiency value partition value of the battery sheet group to be tested to 0.1%;

[0036] D3: Segment the battery conversion efficiency value interval according to the battery conversion efficiency value partition value set in step D2, and obtain several sub-battery conversion efficiency value intervals E;

[0037] D3: According to the sub-cell conversion efficiency value interval E and the battery conversion ef...

Embodiment 2

[0043] On the basis of embodiment 1, the sorting test steps are as follows in the specific work:

[0044] D1: The cell conversion efficiency value of a batch of 101 PERC cells is measured, and the cell conversion efficiency value of each cell is obtained. It can be seen that the cell conversion efficiency value range of this batch of cells is [20.1%, 21.9% %].

[0045] D2: Set the cell conversion efficiency partition value of this batch of cells to 0.1%;

[0046] D3: Divide the measured battery conversion efficiency values into partitions to obtain a total of 19 sub-battery conversion efficiency intervals, namely [Eta 1 = 21.9%], [Eta 2 = 21.8%], [Eta 3 = 21.7%], ... [Eta 18 = 20.2%], [Eta 19 = 20.1%].

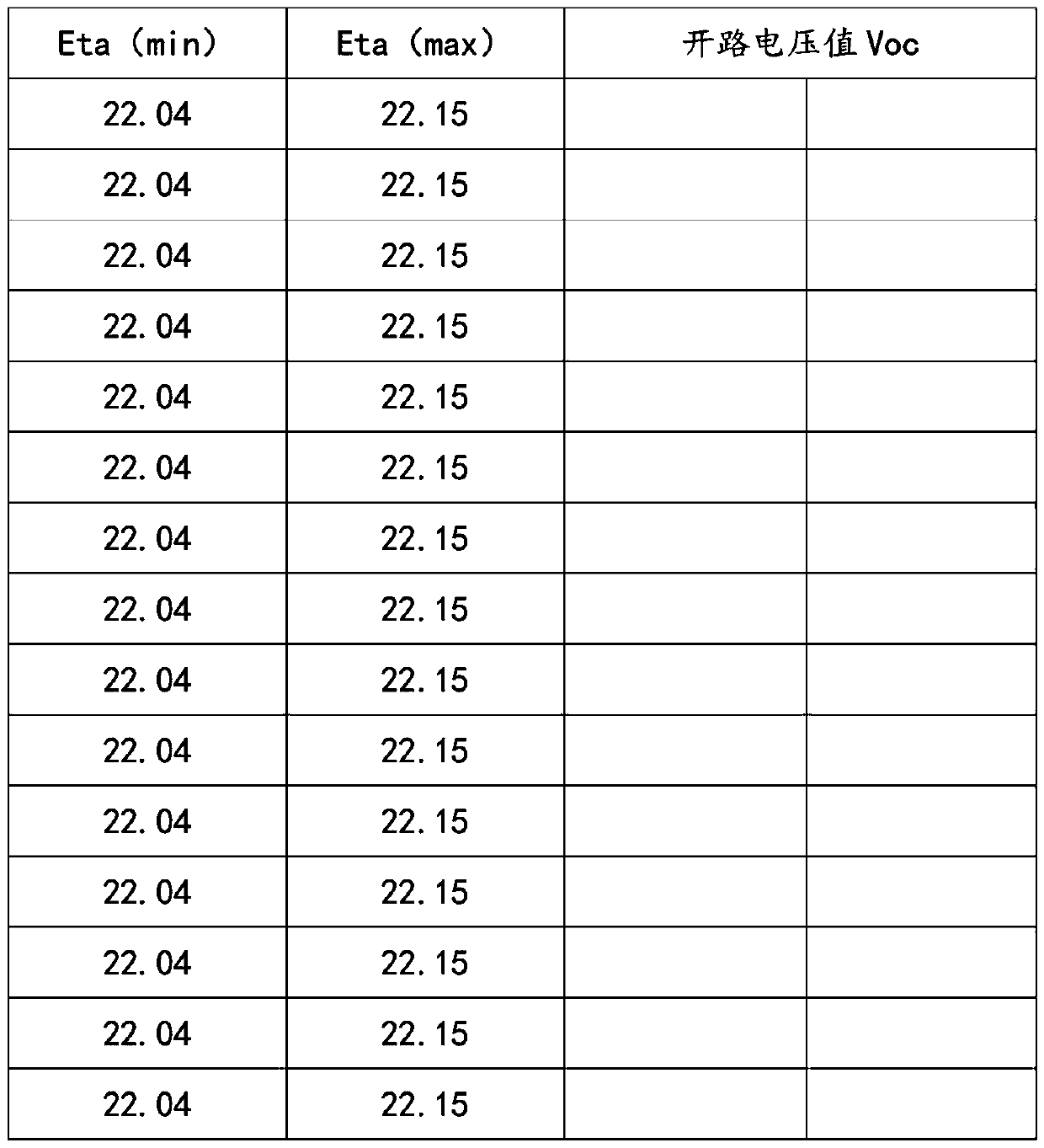

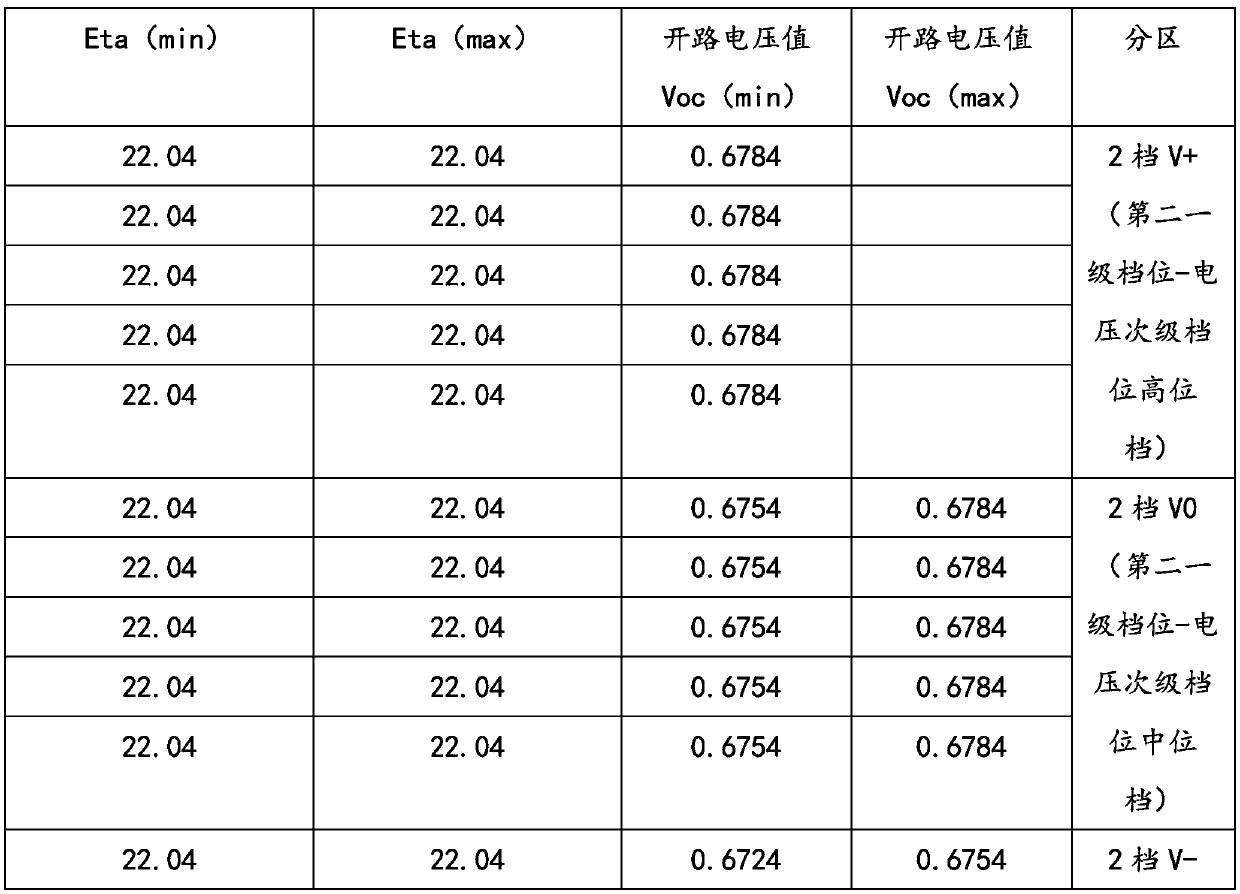

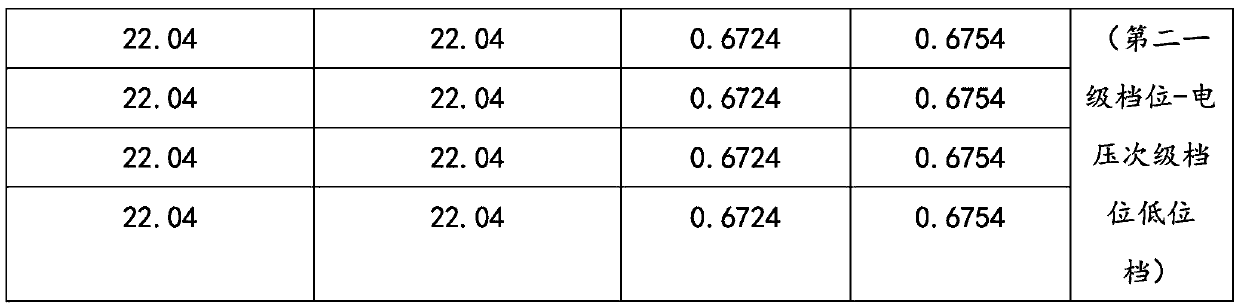

[0047] That is, Eta=21.9% when Eta∈[22.15, 23]. While Eta∈[22.04, 22.15], Eta=21.8%. Refer to Table 1:

[0048] Table 1 Cell test table [Eta 2 = 21.8%]

[0049]

[0050] D4: According to the battery conversion efficiency value range [Eta 1 = 21.9%], [Eta 2 = ...

Embodiment 3

[0068] On the basis of implementation 2, short-circuit current classification B is carried out, including the following steps:

[0069] B1: Conduct a short-circuit current test on the cells in each voltage secondary gear, and obtain the short-circuit current value interval of each cell and the short-circuit current values of all cells in the voltage secondary gear;

[0070] B2: Set the short-circuit current partition value of the battery pack to be tested to 0.2A;

[0071] B3: According to the set short-circuit current partition value, divide the current value interval of the cell in each voltage range into segments to obtain at least one sub-short-circuit current value interval A;

[0072] B4: According to the short-circuit current value of each cell obtained in step B1 and the sub-short-circuit current value interval A obtained in step B3, the cells in the voltage secondary gear are classified, and the short-circuit current value belongs to the same sub-short-circuit curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com