Thermal acoustic insulation and insulation blanket for aircraft

A technology for heat insulation and sound insulation and aircraft, which is used in aircraft parts, transportation and packaging, and deicing devices, etc., can solve the problems of time-consuming and laborious deicing process, low environmental protection, and inability to take off in time, so as to save fuel consumption and prevent the effect of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

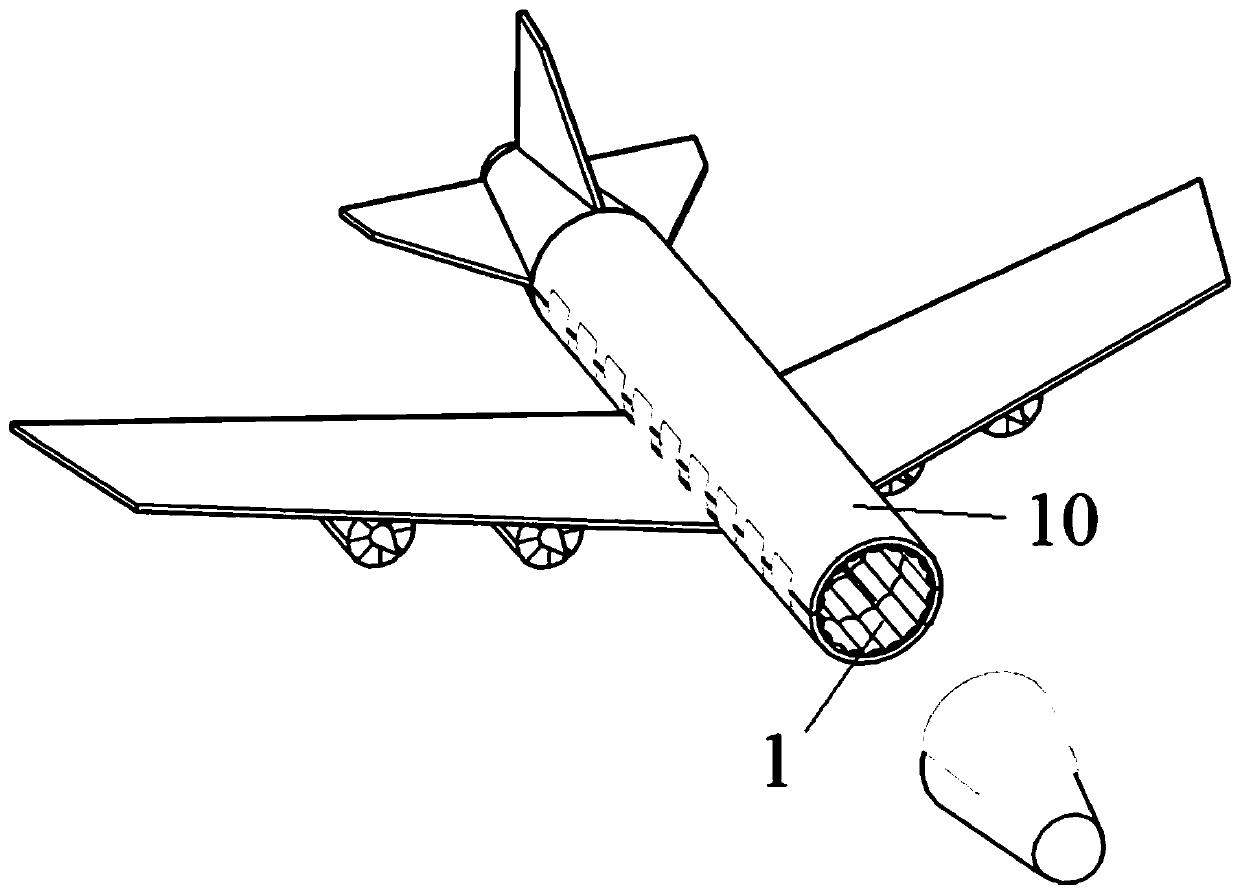

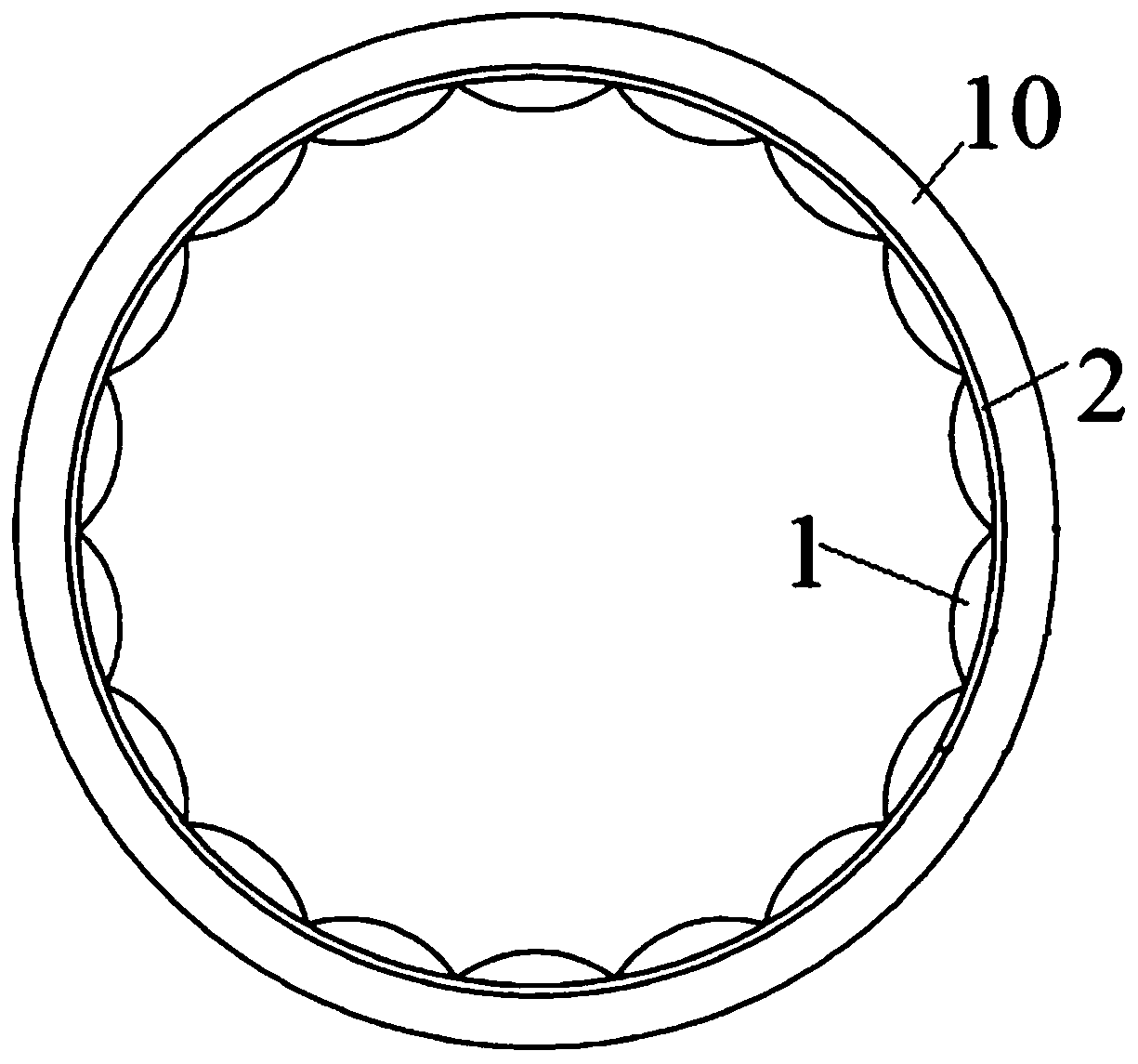

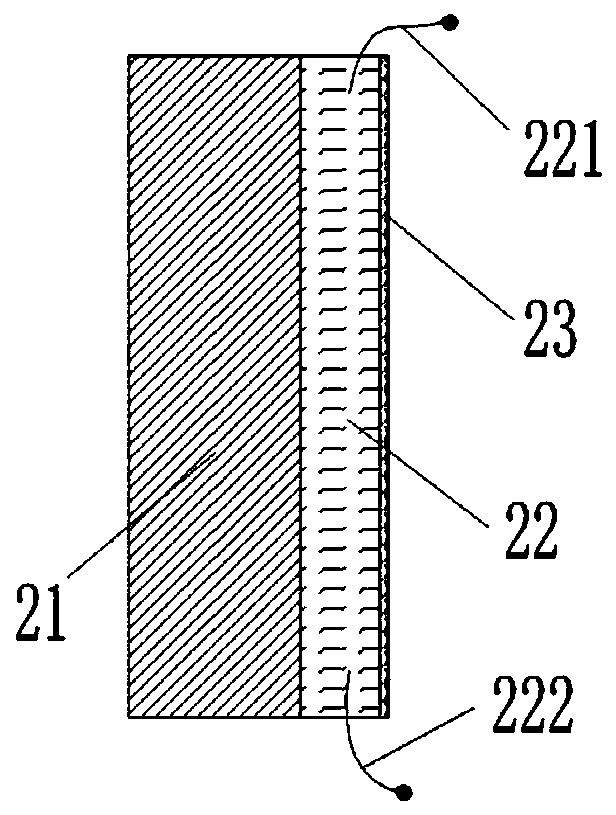

[0019] see in conjunction Figure 1 to Figure 3 As shown, according to the embodiments of the present invention, the present invention provides a heat and sound insulation blanket for an aircraft, the inner lining is connected to the fuselage wall 10 of the aircraft, so as to separate the high or low temperature and noise from the outside of the aircraft. The interior of the cabin is effectively insulated. The aircraft can be, for example, a passenger aircraft. The heat and sound insulation blanket includes a heat and sound insulation blanket body 1, and the side of the heat and sound insulation blanket body 1 facing the fuselage wall 10 has a heat generating layer 2, and / or, the heat-generating layer 2 is provided on the side of the heat and sound insulation blanket body 1 away from the fuselage wall 10 . In this technical solution, since a heating layer 2 is provided on one side of the existing heat-insulating and sound-insulating blanket, the fuselage wall 10 can be heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com