Truss tower and spanning construction protection equipment comprising same

A technology of protective equipment and truss towers, which is applied in the field of spanning construction protective equipment and truss towers, can solve the problems of complex use, large lateral force and moment of the main tower, complex operation, etc., and achieve easy manufacture and use, excellent mechanical properties, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

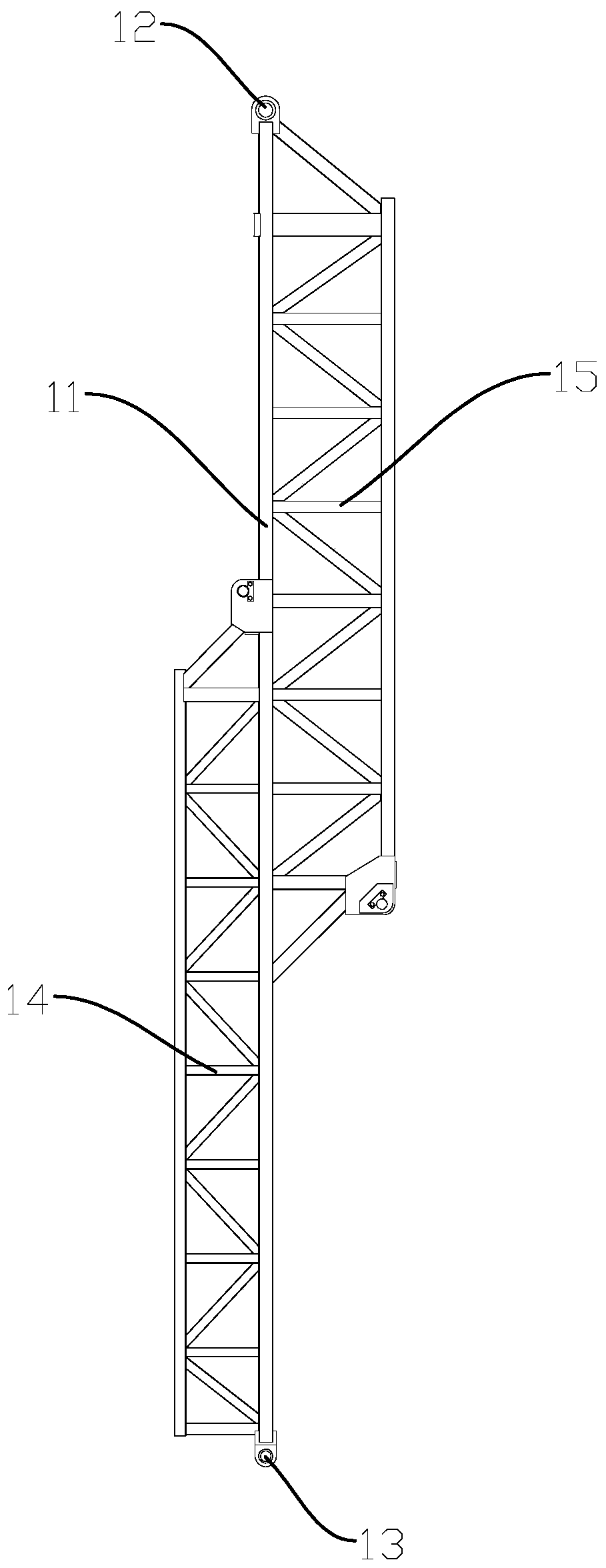

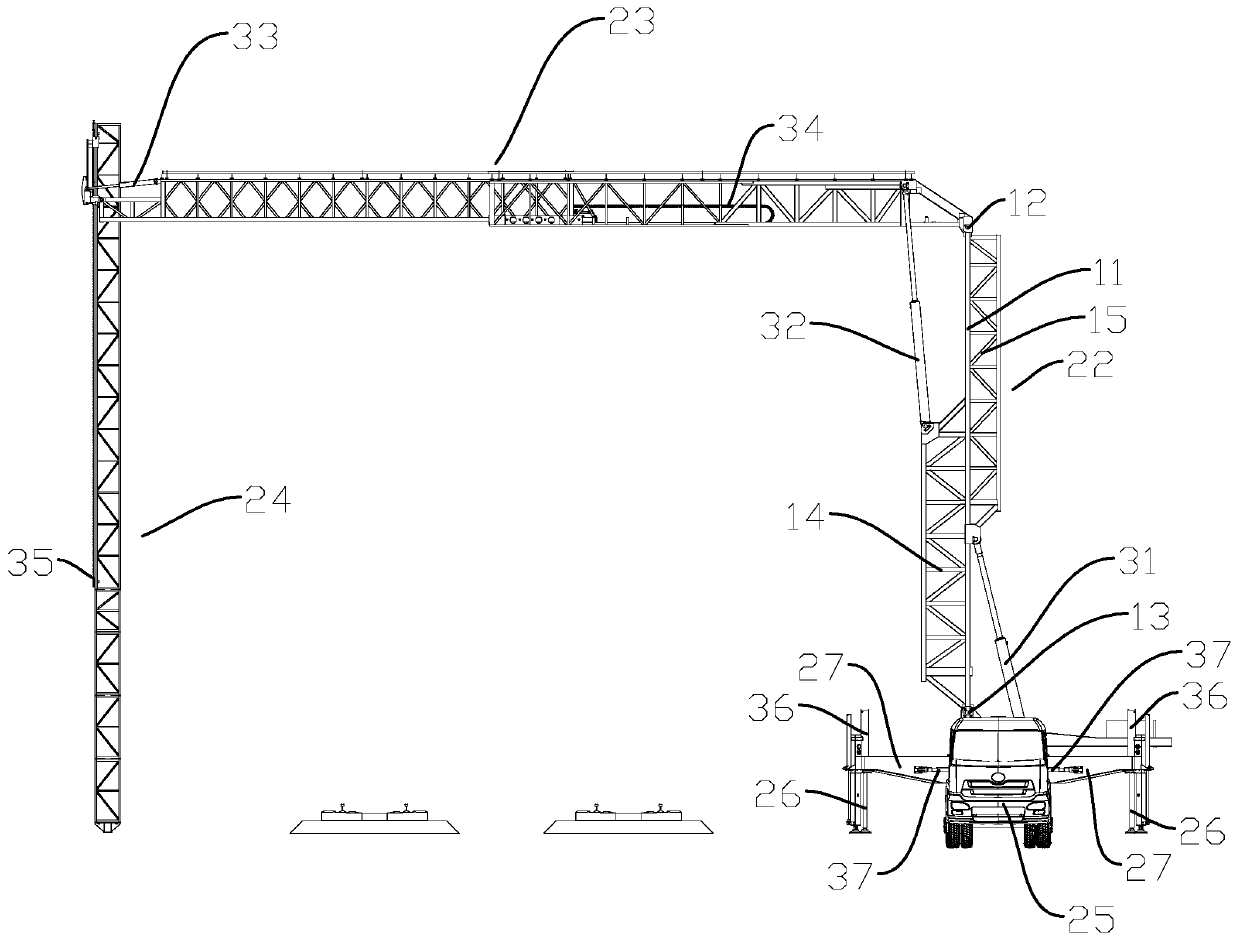

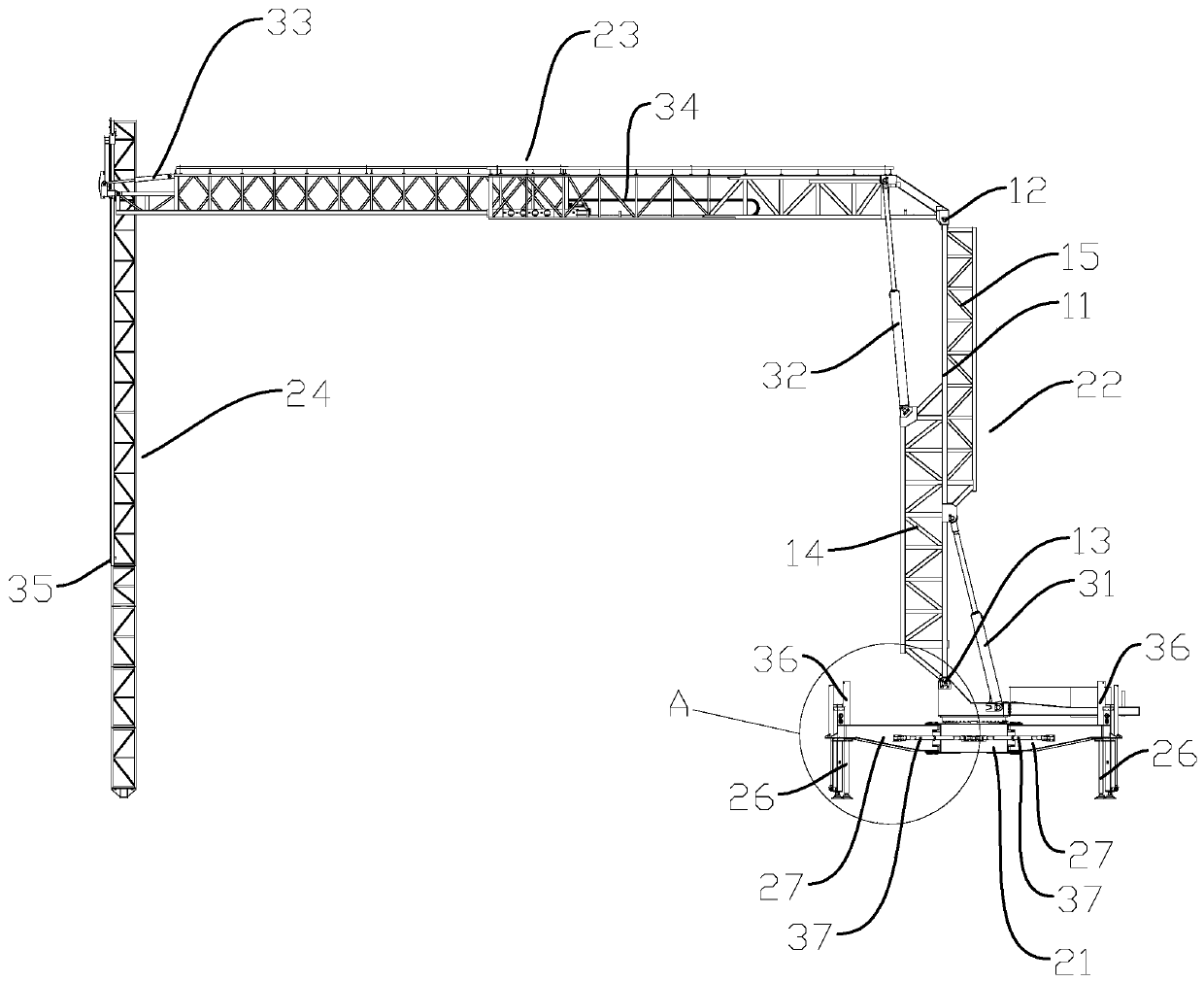

[0023] Reference figure 1 , The present invention provides a truss tower, including a base frame 11, the top and bottom of the base frame 11 are respectively provided with an upper connection part 12 and a lower connection part 13, the front part of the base frame 11 is provided with a front truss part 14, the rear part A rear truss part 15 is provided, the front truss part 14 is located at the lower part of the base frame 11, and the rear truss part 15 is located at the upper part of the base frame 11. In the truss tower of the present invention, the upper connecting part 12 and the lower connecting part 13 are respectively arranged at the top and bottom of the main frame body, and the rear truss part 15 is arranged at the upper part of the rear part of the main frame body, and the front truss part 14 It is installed at the lower part of the front part of the main frame body. Compared with the traditional columnar truss tower, it can ensure the structural strength of the truss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com