Construction method of integral hydraulic box girder formwork

A construction method and technology of hydraulic tanks, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficulty in construction, high cost of curved box girders, and inability to reuse, so as to save water resources and labor Low cost, simple structure, and the effect of preventing water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0028] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

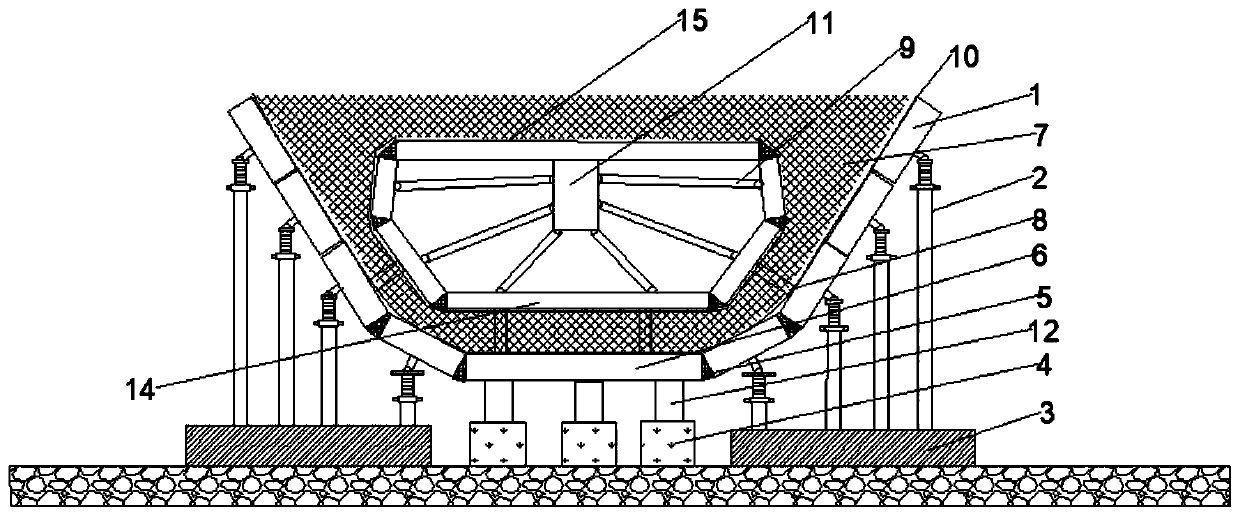

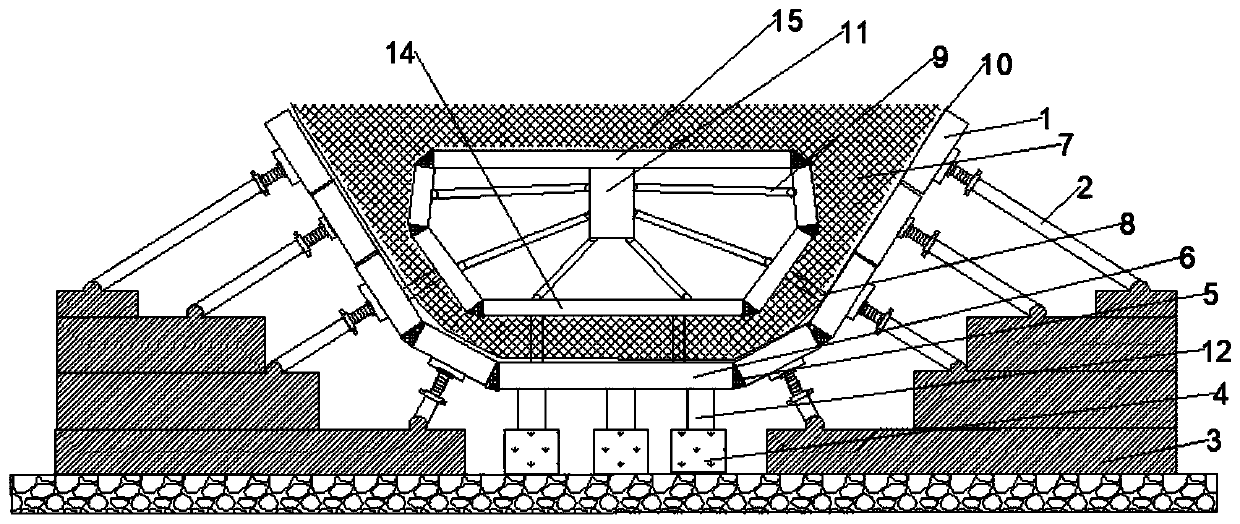

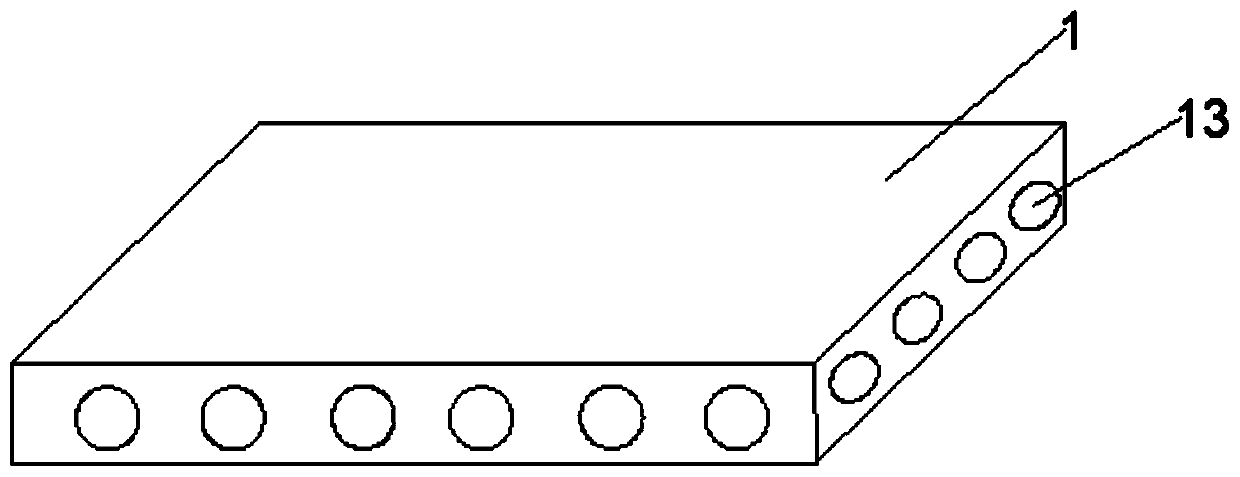

[0029] Such as Figure 1-4 As shown, the present invention provides a kind of integral hydraulic box girder formwork construction method, and concrete steps comprise:

[0030] Step 1. According to the drawings of the bridge to be constructed, divide the bridge into multiple curved sections and multiple straight sections, and obtain the space alignment of the box girders of the multiple curved sections. The pouring method of the straight section of the box girder is carried out;

[0031] Step 2, erection of the construction platform 4: determine the orientation of the constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com