Large-diameter single-pile steel pipe pile internal inserting transition section grouting construction system and method

A technology of steel pipe piles and transition sections, applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve problems affecting the operation and service life of wind turbines, reduce the risk of emergency treatment, high construction accuracy, and save offshore operations the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The idea, specific structure and technical effects of the present application will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present application.

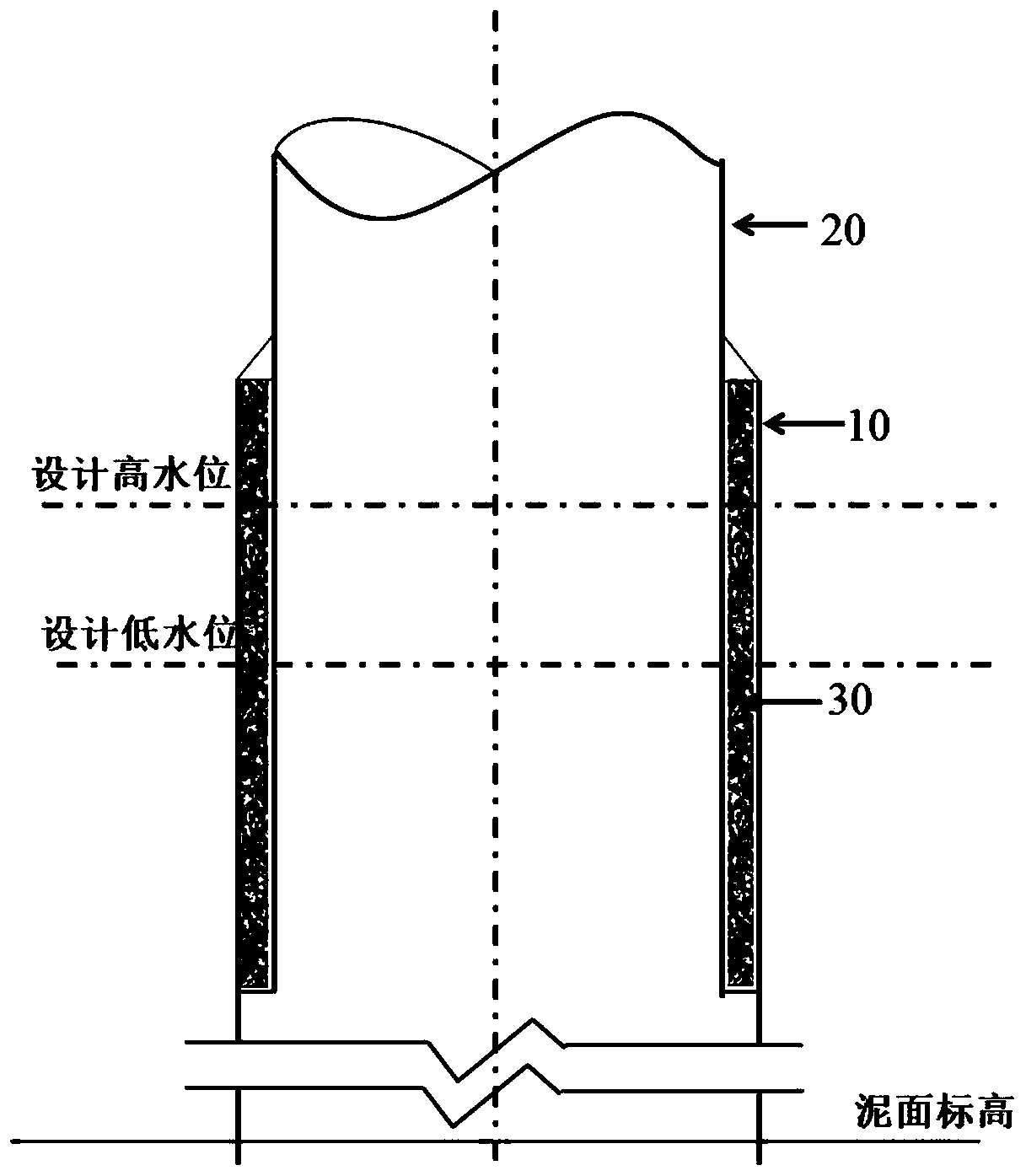

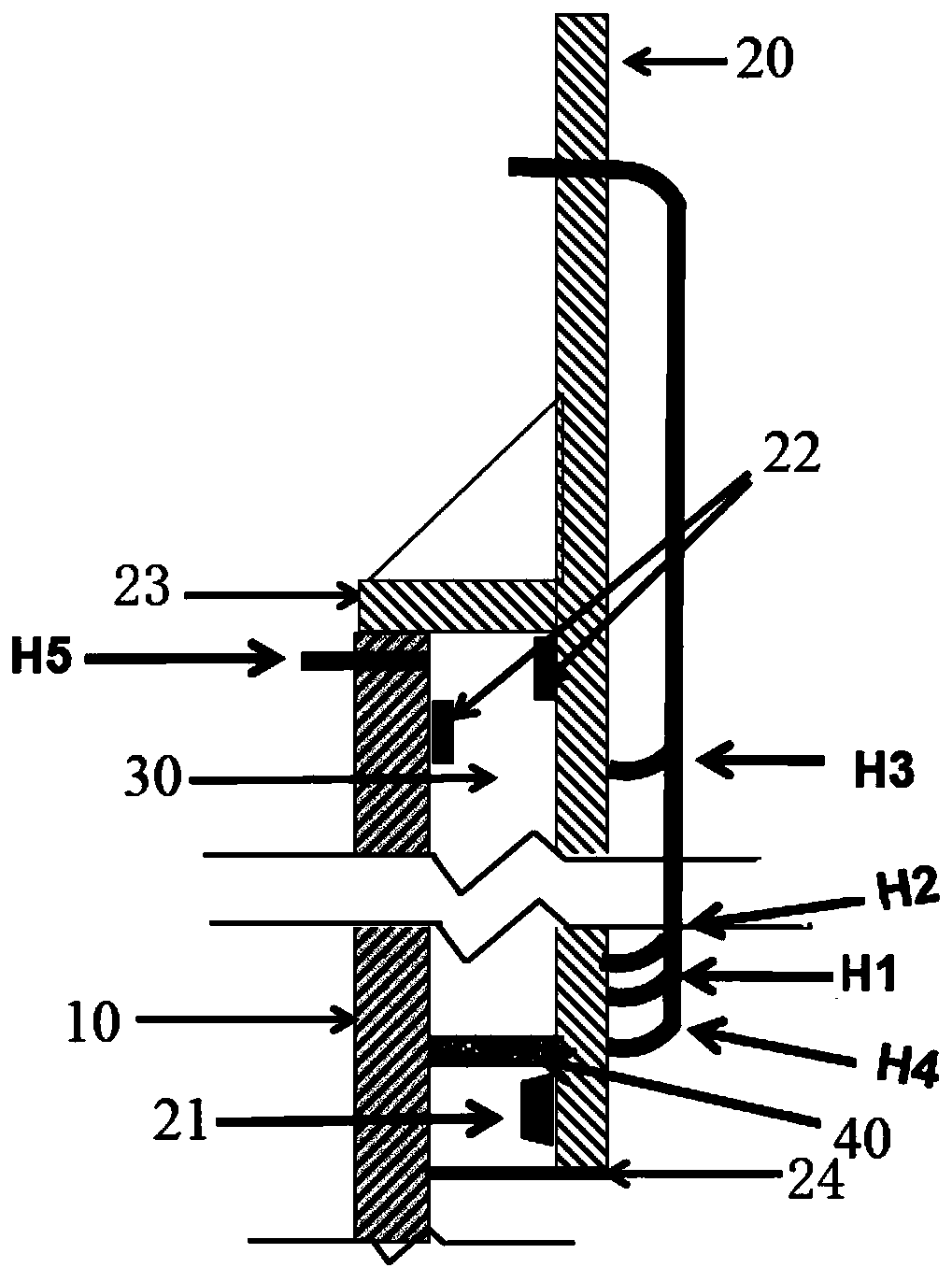

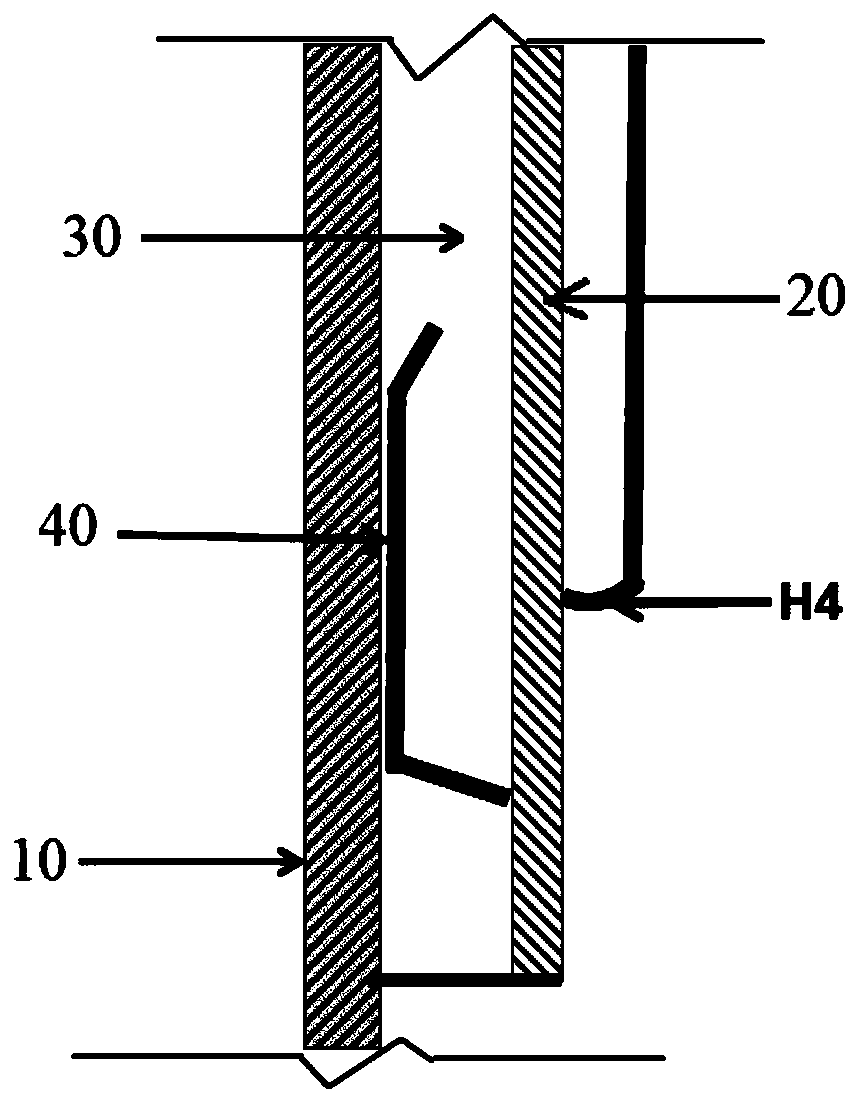

[0031] Such as Figure 1 to Figure 5 As shown, the grouting construction system of the large-diameter single steel pipe pile interpolation transition section in this embodiment includes: steel pipe pile 10 and interpolation transition section 20, the ring plate 23 set on the interposition transition section 20 and the The steel pipe pile 10 is fixedly connected, and the bottom of the inserted transition section 20 is connected to the steel pipe pile 10 through a mounting piece, wherein the grouting between the inserted transition section 20 and the steel pipe pile 10 The area 30 is poured with grout. This application adopts the construction technology of "fixed connection to the steel pipe pile 10 at the upper part of the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com