Preparation device of semisolid slurry

A semi-solid slurry and preparation device technology, applied in lighting and heating equipment, crucible furnaces, furnaces, etc., can solve the problems of uneven temperature inside and outside the slurry, poor uniformity of the temperature field of the slurry, etc., and avoid melt spillage. , Improve uniformity and reduce the effect of temperature difference between inside and outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

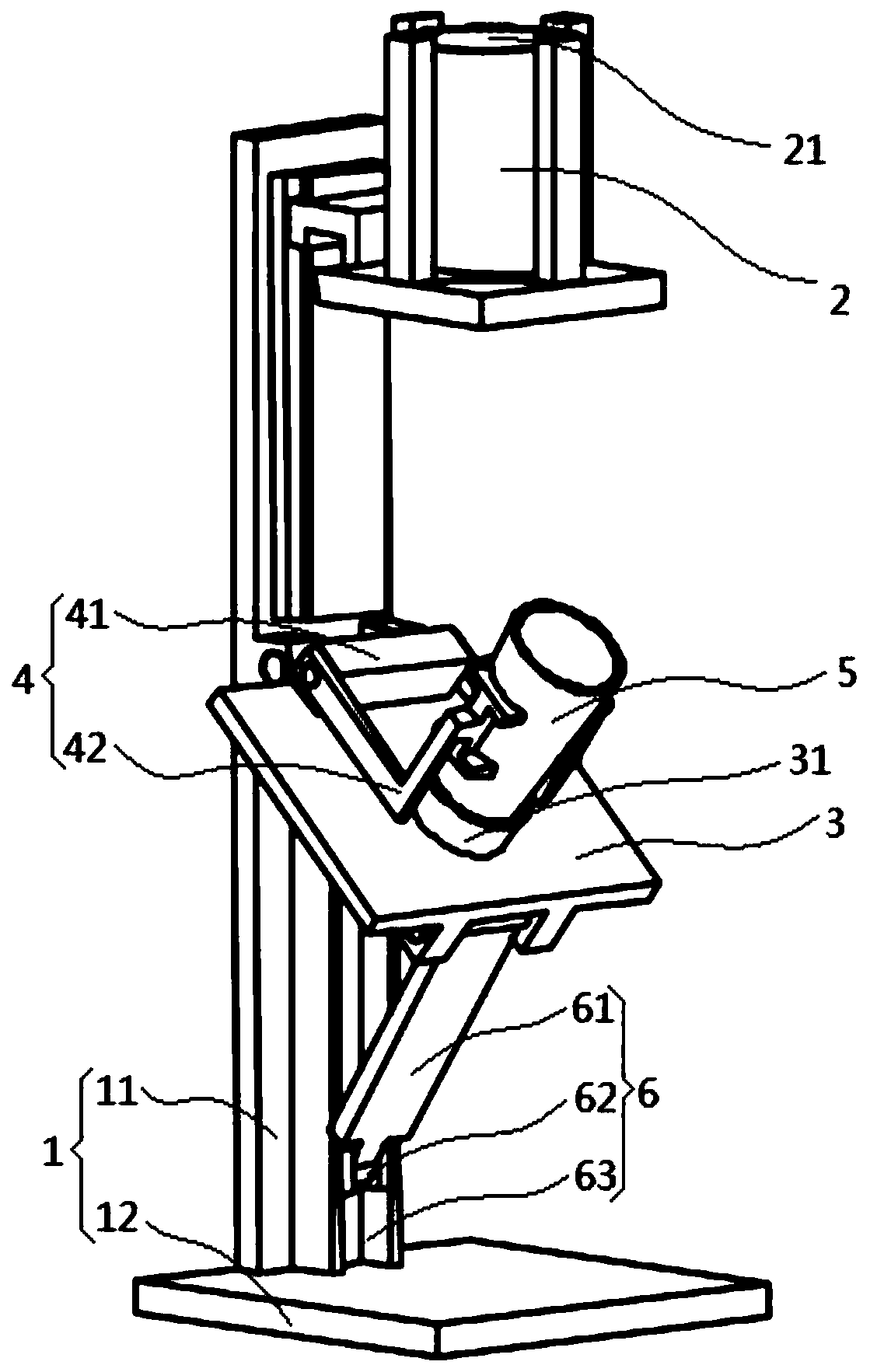

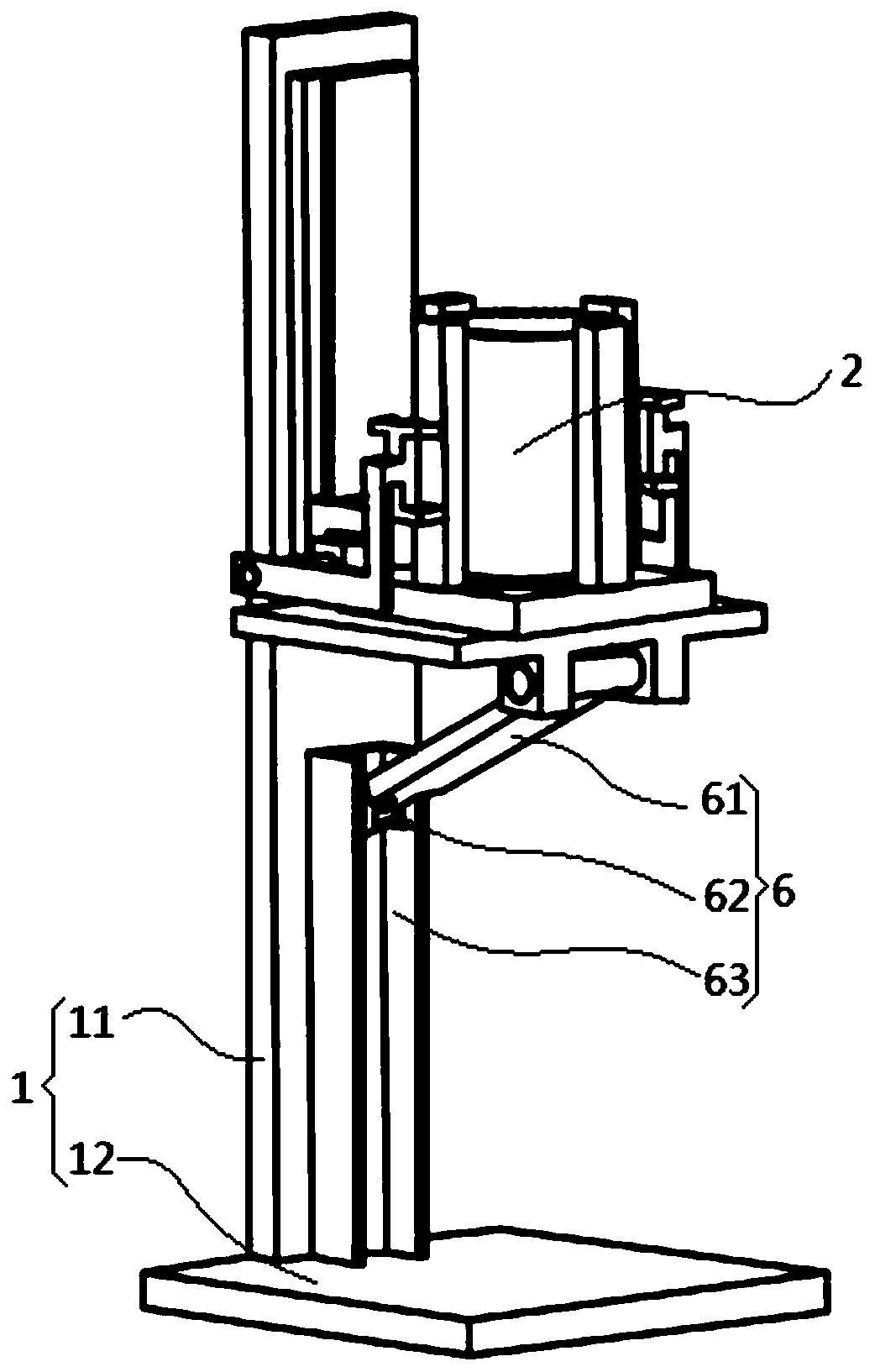

[0037] According to the preparation device of the semi-solid melt in the embodiment of the present invention, since the crucible 5 containing the melt can be rotated relative to the support 1, the melt can be injected into the crucible 5 more conveniently, avoiding the spillage of the melt during the melt injection process. Phenomenon. In addition, since the heating device 2 is slidably disposed on the support 1 and the heating device 2 can be sleeved on the outside of the crucible 5 to heat the crucible 5 . Therefore, in the process of natural cooling of the melt, when the temperature of the melt drops below the liquidus line, the heating device 2 can heat the crucible 5 and the surface melt, which reduces the temperature difference between the inside and outside of the melt and improves the temperature of the melt. Uniformity of the temperature field.

[0038] What needs to be added here is that in the implementation of the present invention, the heating method of the heati...

Embodiment

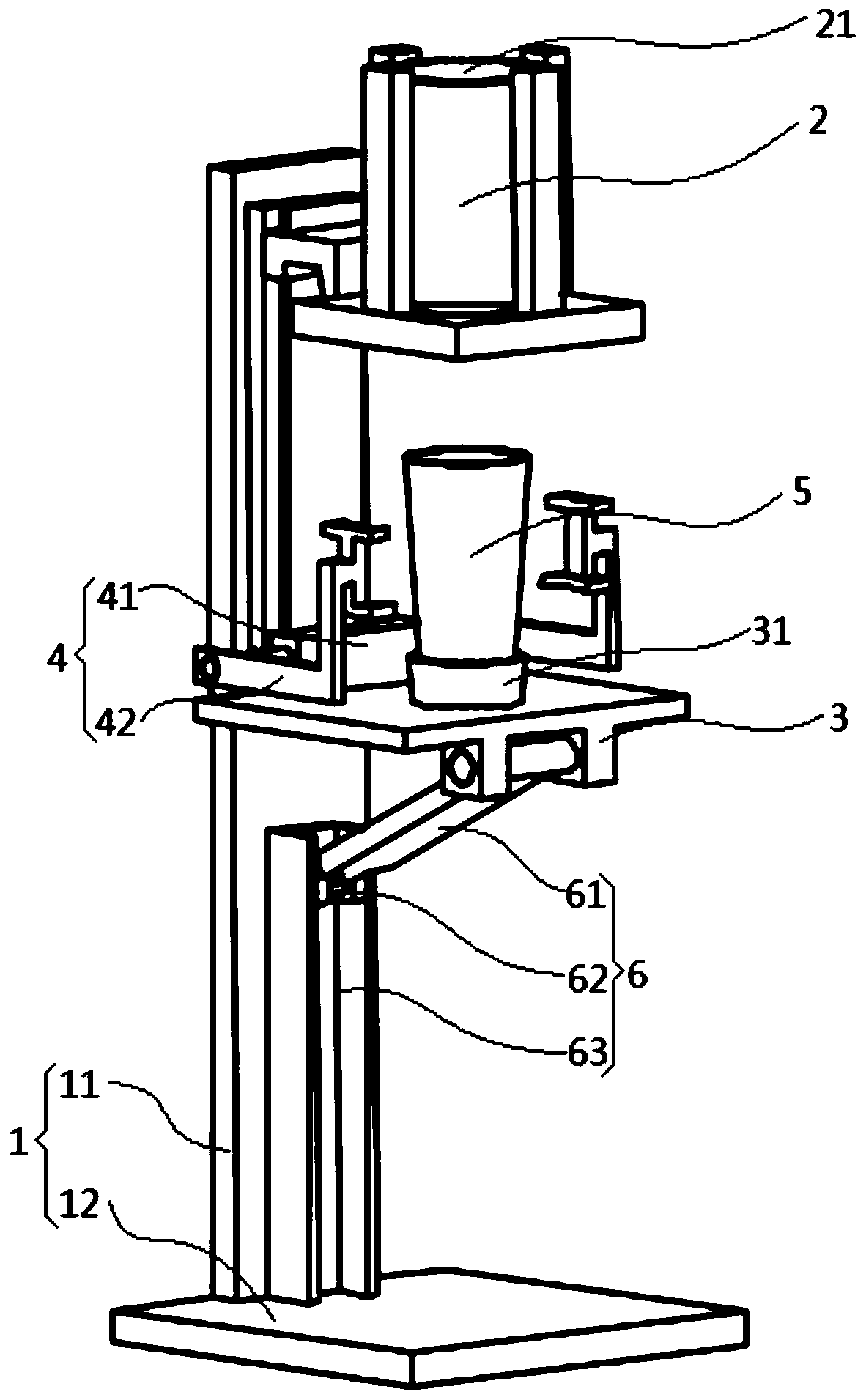

[0055] Such as figure 1 As shown, the preparation device for semi-solid slurry includes a support 1, a heating device 2, a fixed plate 3, a clamping assembly 4, a crucible 5 and an angle adjustment mechanism 6, the fixed plate 3 is rotatably arranged on the support 1, and the fixed plate 3 There is an insulating cover 31 on the top, and the crucible 5 fits in the insulating cover 31. The crucible 5 is configured to hold the melt, and the heating device 2 is slidably arranged on the bracket 1. The heating device 2 has a heating hole 21, and the heating device 2 can be set It is arranged outside the crucible 5 to heat the crucible 5 .

[0056] The support 1 includes a chassis 12 and a column 11 , the lower end of the column 11 is connected to the chassis 12 , and the heating device 2 and the fixing plate 3 are both arranged on the column 11 . The clamping assembly 4 includes a driving member 41 and a clamp 42. The driving member 41 is formed as a cylinder and is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com