A method for distinguishing red scale and red corrosion products of hot-rolled steel

A technology for corrosion products and hot-rolled steel, which is used in the analysis of materials, the preparation of test samples, and the material analysis by optical means. , to achieve the effect of short test time, reduced rejection rate and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

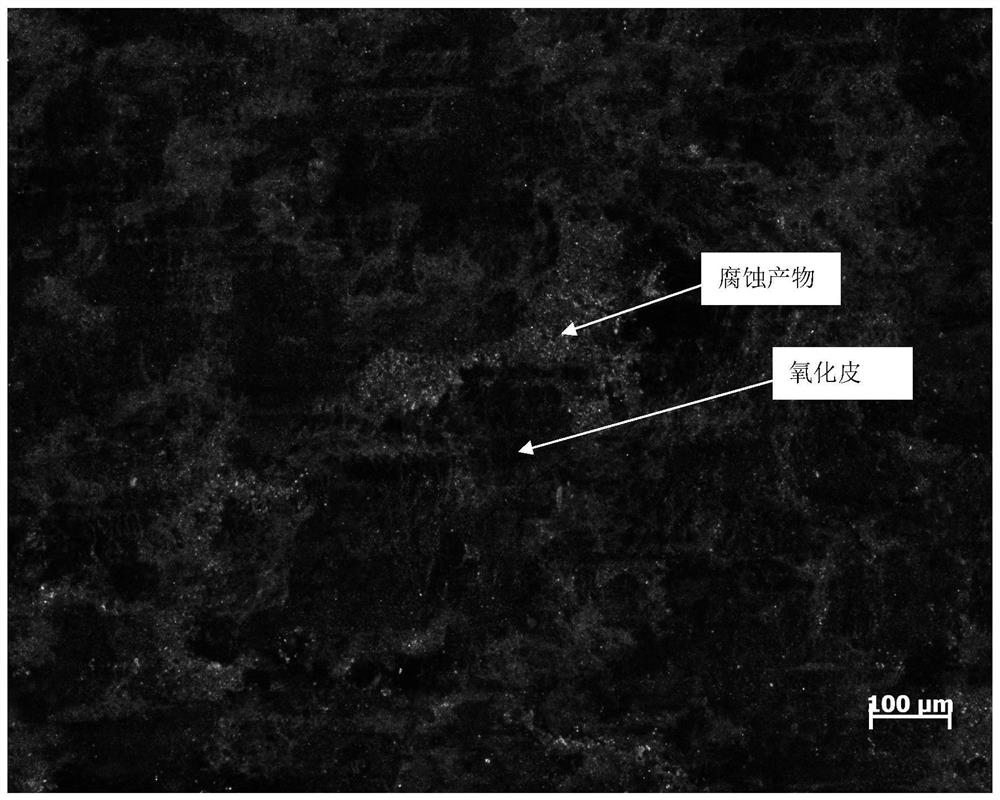

[0015] The X65 pipeline steel plate produced by hot rolling controlled rolling and controlled cooling process has a thickness of 16mm and a reddish color. Using a ZEISS Axio Imager M2m metallurgical microscope equipped with a polarizer and an analyzer, this method is used to distinguish red substance types, including the following steps:

[0016] (1) Sample preparation. Cut the X65 steel with red surface into 30×30×16mm samples by machine, and keep the original surface state of the samples from damage.

[0017] (2) Observe the sample with parallel light. Disable the polarizer and analyzer, pull out the polarizer, switch to the bright field imaging mode, observe the surface of the sample with the parallel light of the microscope, adjust the microscope imaging mode to color, adjust the magnification to 100 times as needed, and find the object to be observed the target area;

[0018] (3) Observe the sample with polarized light. Use the polarizer and analyzer, push the polariz...

Embodiment 2

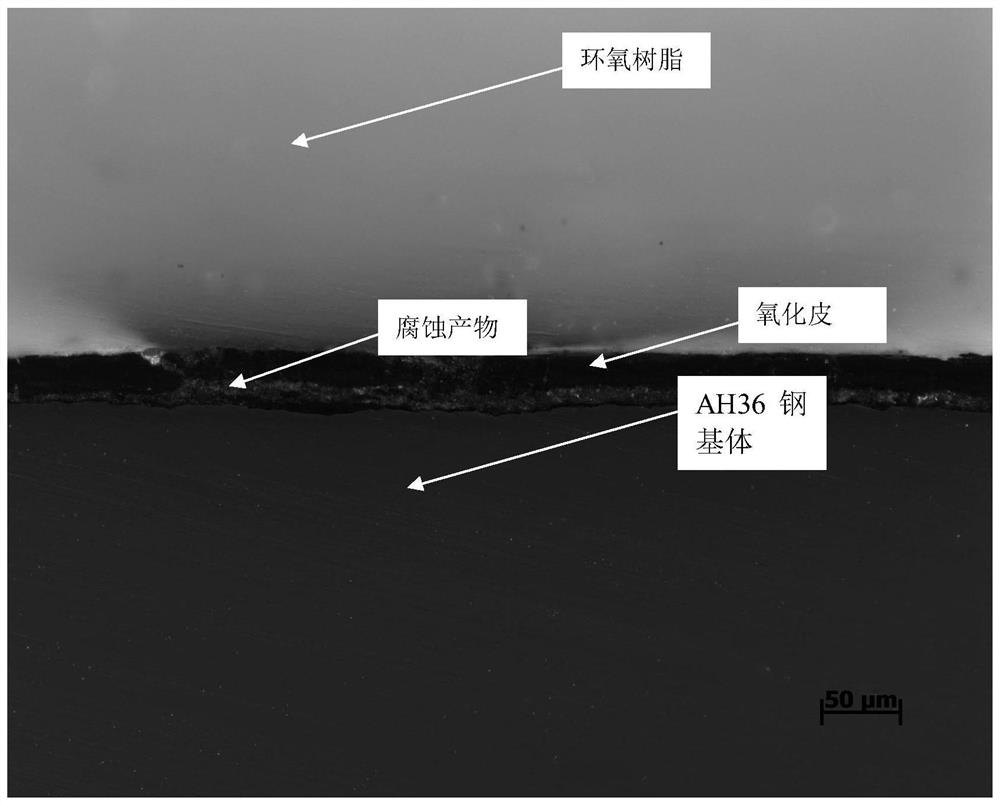

[0022] The AH36 ship plate steel produced by the hot rolling process, the thickness of the steel plate is 16mm, and it is placed in the warehouse for 60 days. Using a ZEISS Axio Imager M2m metallurgical microscope equipped with a polarizer and an analyzer, this method is used to distinguish red substance types, including the following steps:

[0023] (1) Sample preparation. Seal the surface of the red X65 steel with epoxy resin to keep the original surface state of the sample undamaged, and cut it into 30×30×16mm samples by machine.

[0024] (2) Observe the sample with parallel light. Disable the polarizer and analyzer, pull out the polarizer, switch to the bright field imaging mode, observe the surface of the sample with the parallel light of the microscope, adjust the microscope imaging mode to color, adjust the magnification to 200 times as needed, find the object to observe the target area;

[0025] (3) Observe the sample with polarized light. Use the polarizer and ana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com