Cylindrical object processing device

A processing device, cylindrical technology, applied in the direction of circuit/collector parts, electrical components, connections, etc., can solve the problems of inability to achieve local control, peeling off the outer quilt, etc., to achieve a high degree of automation, high processing efficiency, working principle simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

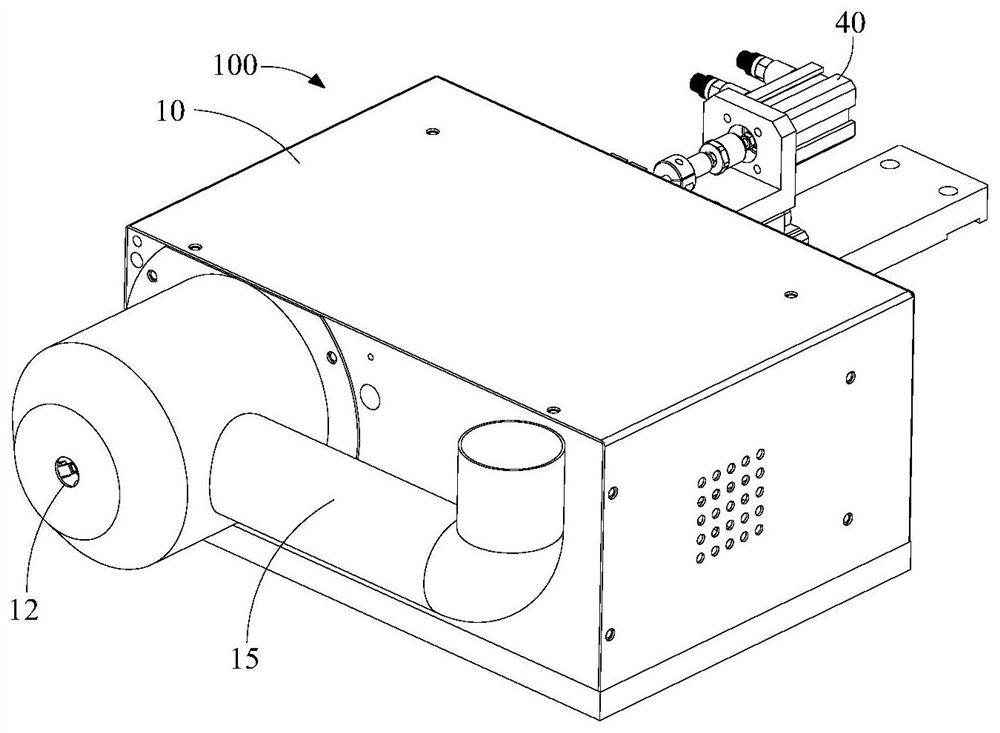

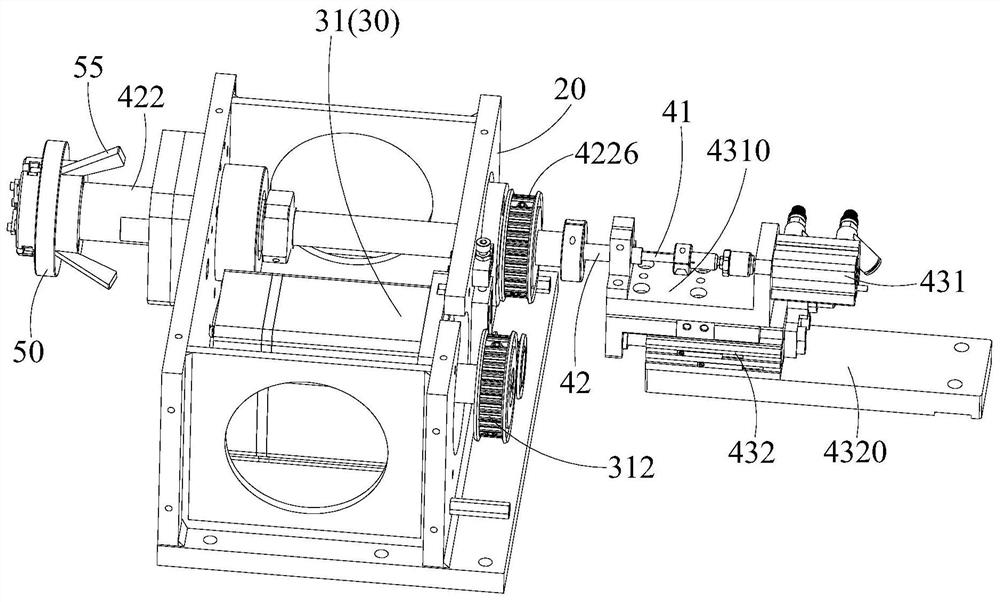

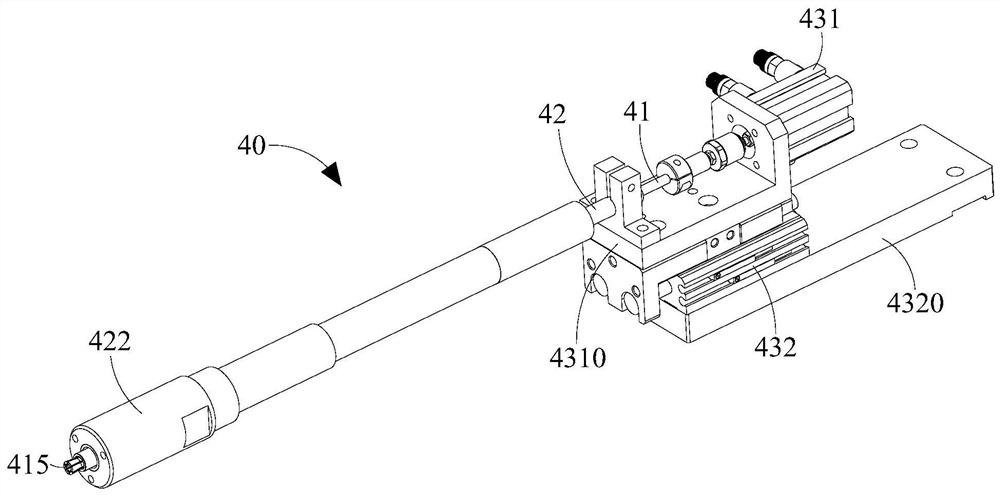

[0024] see Figure 1 to Figure 10 As shown, the present invention discloses a processing device 100 for cylindrical objects, such as cables and wires. The cylindrical object processing device 100 includes a protective cover 10 , a frame 20 , a power assembly 30 , a positioning assembly 40 and a processing assembly 50 .

[0025] Protective cover 10 covers frame 20, power assembly 30, positioning assembly 40 and processing assembly 50 outside, protective cover 10 front end is provided with feeding hole 12, and side is provided with discharge pipe 15, is communicated with processing assembly 50, is used for processing Waste chips generated during the operation of the assembly 50 are discharged outside the cylindrical object processing device 100 .

[0026] The power assembly 30 , the positioning assembly 40 and the processing assembly 50 are installed on the frame 20 respectively.

[0027] The power assembly 30 is preferably composed of a motor 31 and a synchronous belt (not sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com