Full-automatic zoom motor coil winding machine

A fully automatic, winding machine technology, applied in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve the problems of loose winding, troublesome threading, high cost, etc., to ensure the accuracy of wire arrangement and avoid winding loose The effect of opening and ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

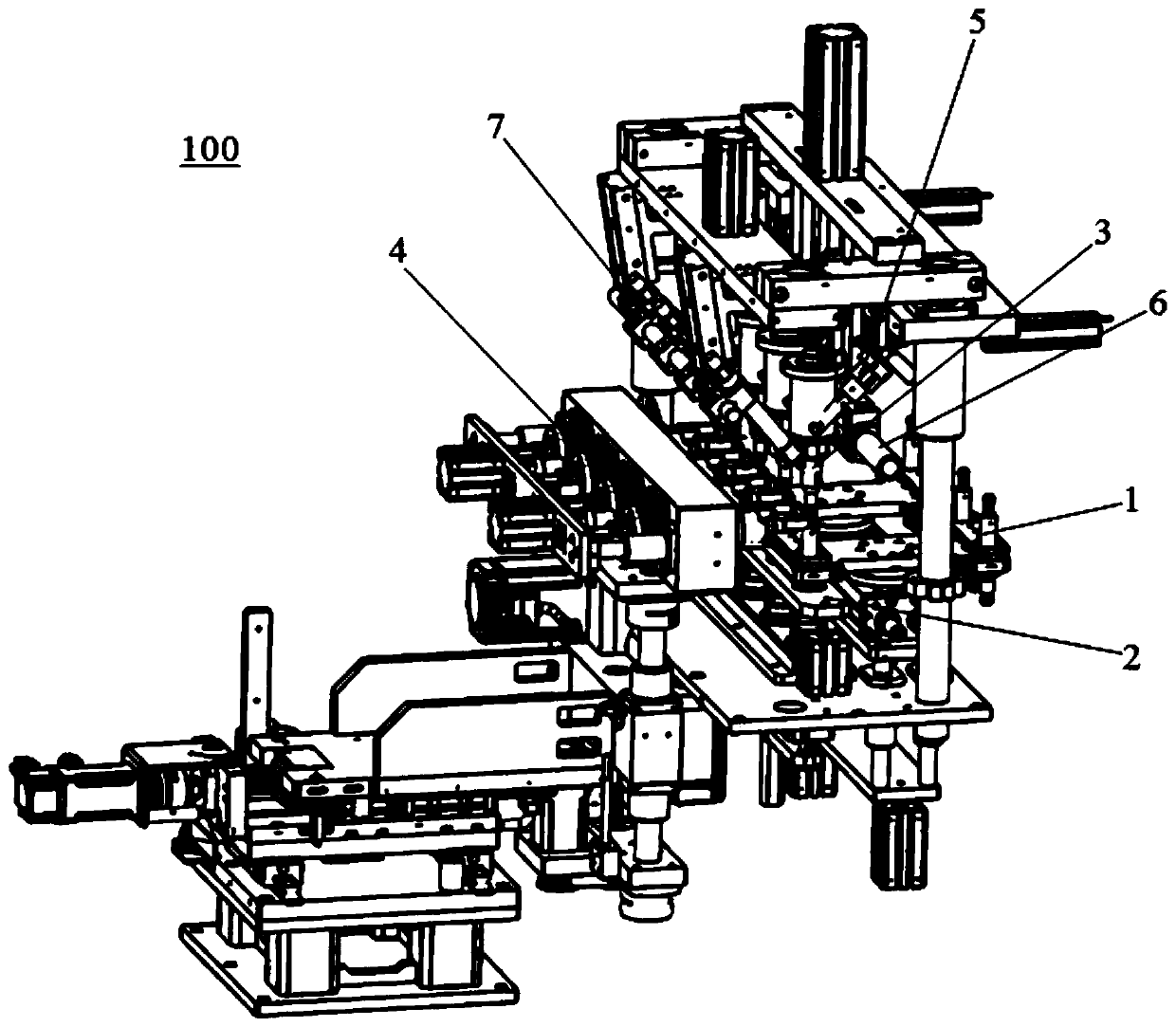

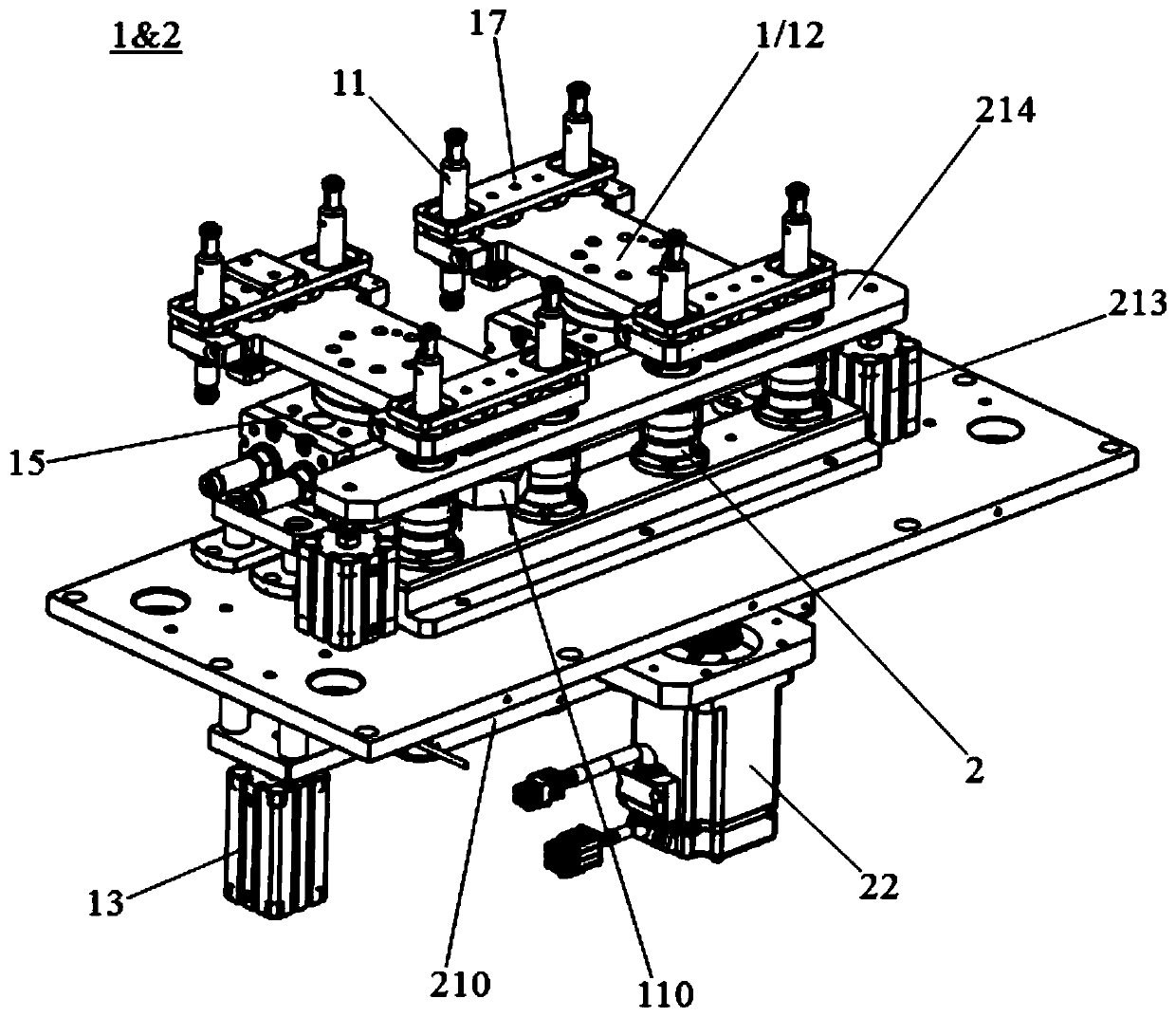

[0049] Please refer to Figure 1-Figure 17, the present embodiment is a fully automatic zoom motor coil winding machine 100, which includes a loading jig unit 1 provided with a jig shaft 11 supporting a product, and an indexing unit for driving the jig shaft 11 in the feeding jig unit 1 to rotate Spindle rotation unit 2, the spindle cooperating with the jig shaft 11 to compress the product, the cooperating pressing unit 3, the winding mechanism for winding the product 4, the clamping unit for clamping the thread 5, the waste suction line for absorbing the waste line Unit 6 and heat gun assembly 7 for heating the copper wire.

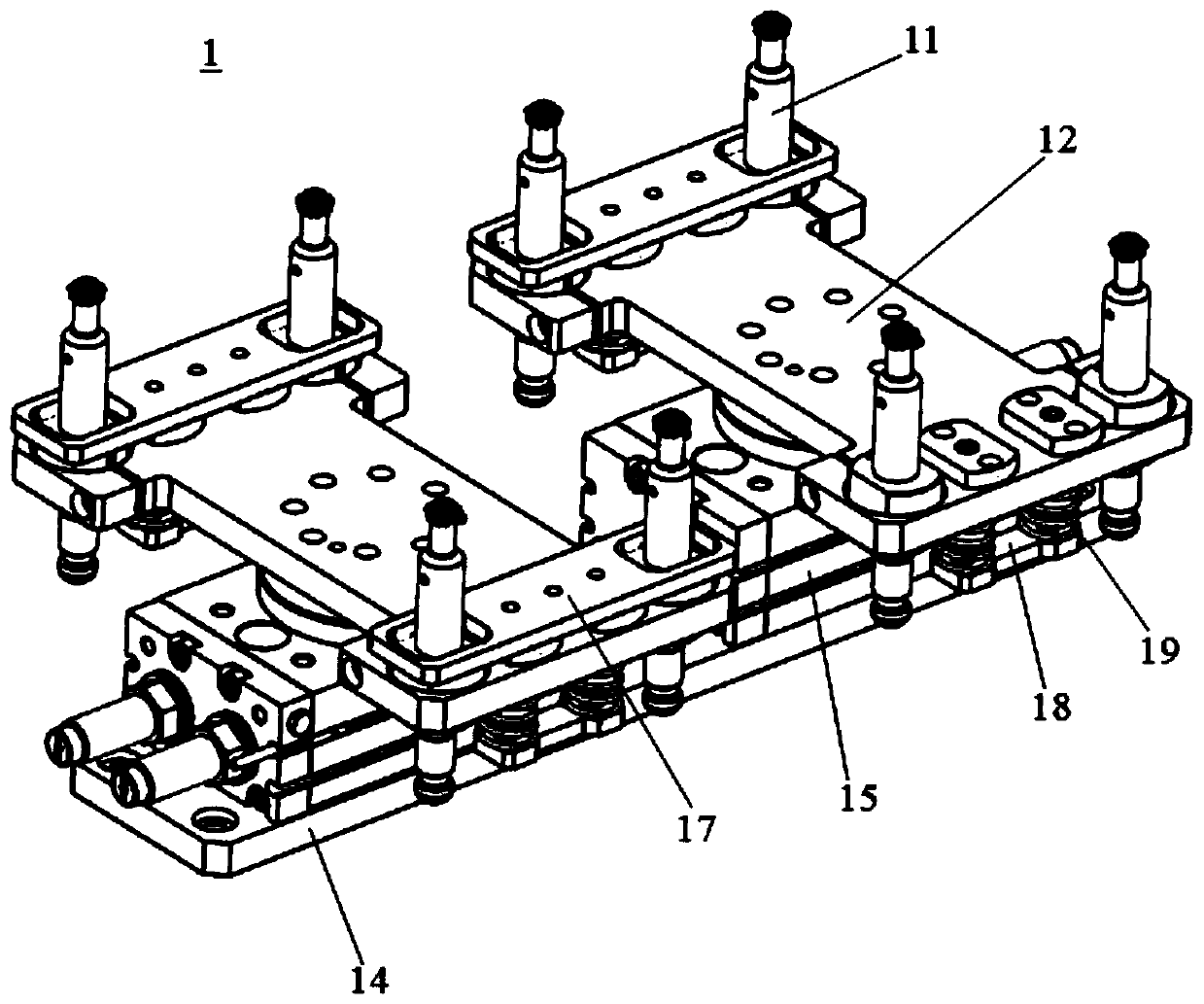

[0050] The feeding fixture unit 1 includes a first cylinder 13, a first support plate 14 driven by the first cylinder 13 to move up and down, at least one rotary cylinder 15 fixed on the first support plate 14, and driven to rotate by the rotary cylinder 15 The rotary plate 12, several jig shafts 11 placed on the rotary plate 12 and located on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com