Fire extinguishing system and fire extinguishing method thereof

A fire extinguishing system and fire-fighting technology, which is applied in fire rescue and other fields, can solve the problem of inconvenient winding process, and achieve the effect of easy unwinding and winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

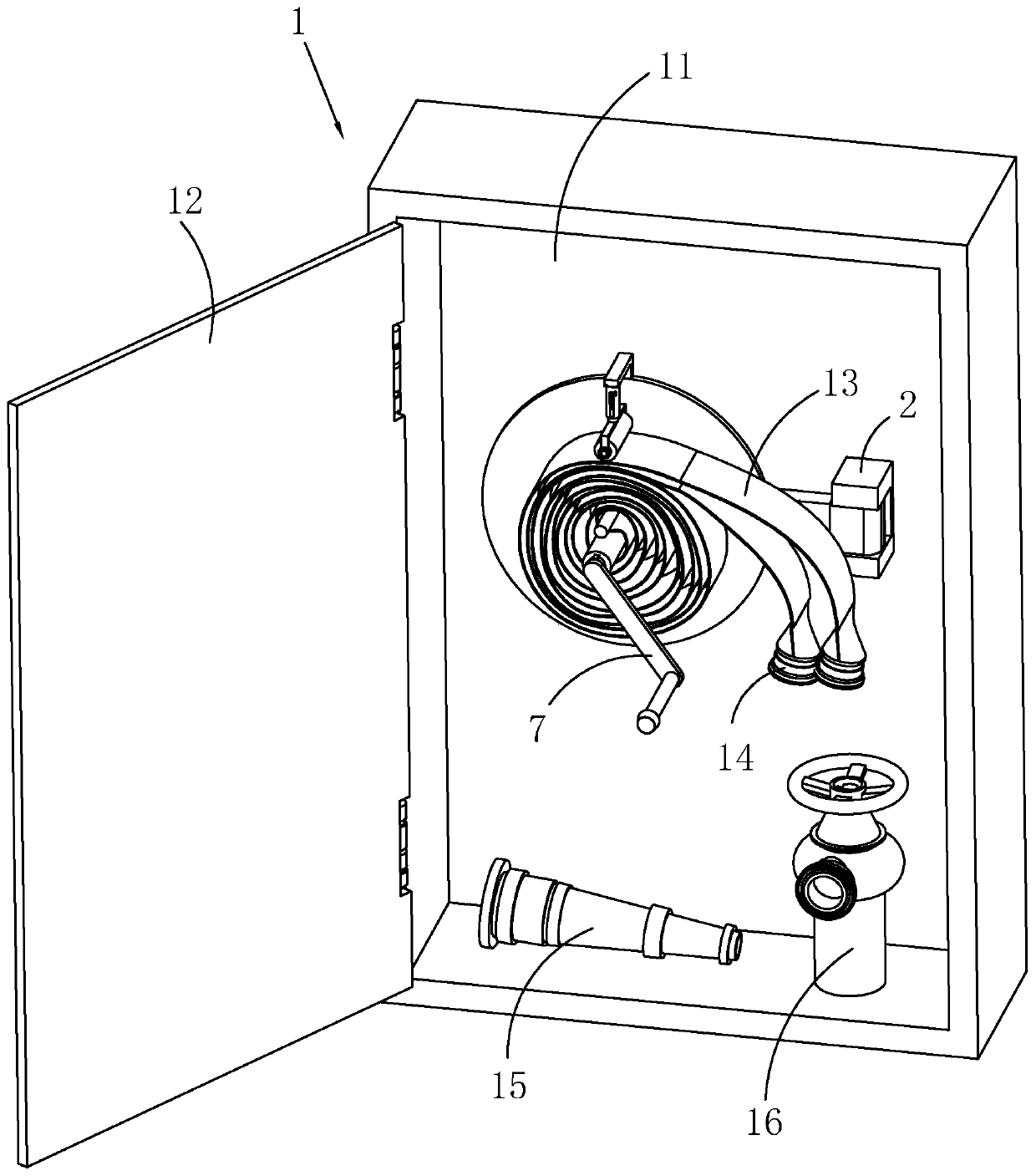

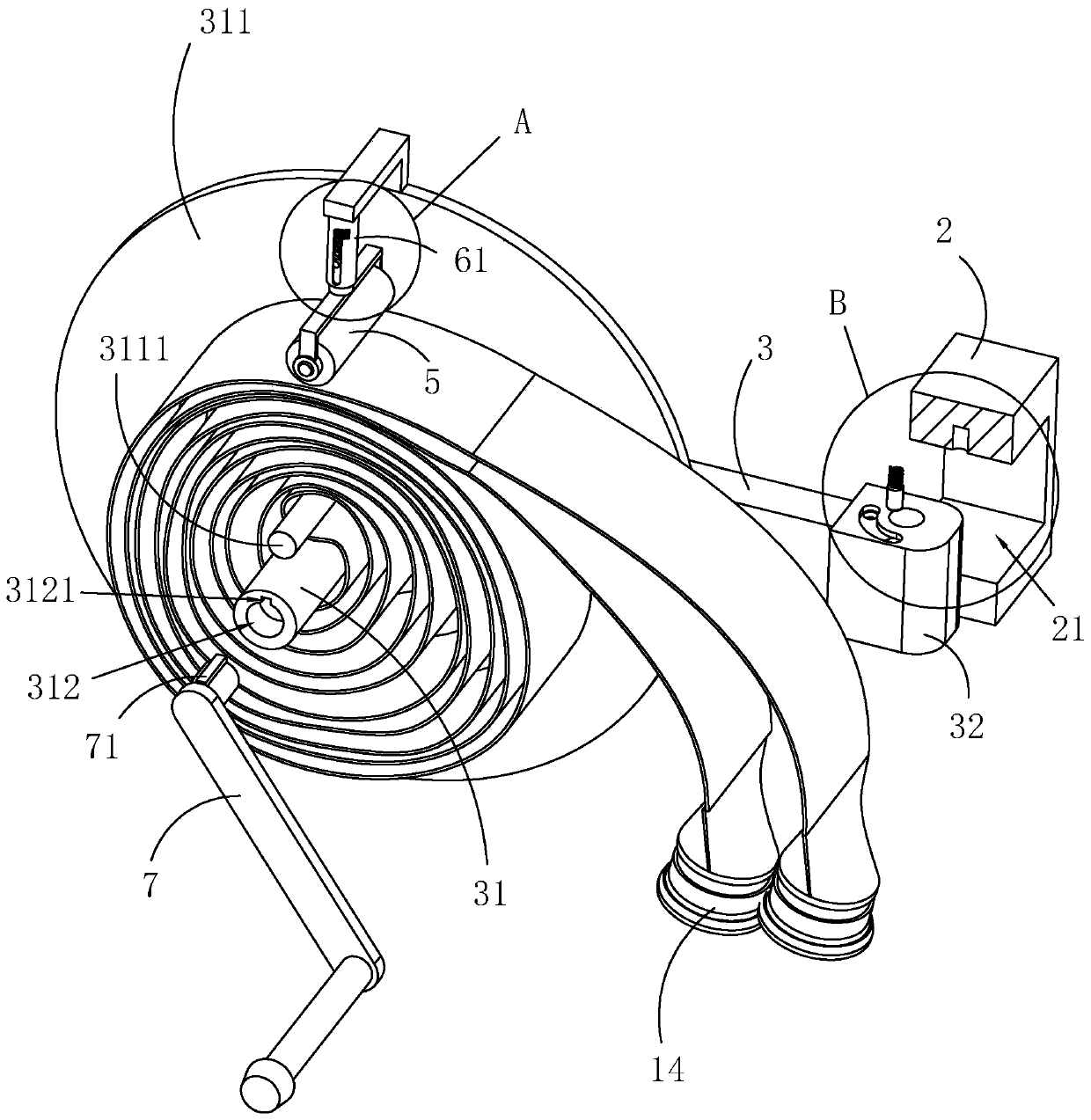

[0041] Such as figure 1 , 2 As shown, a fire extinguishing system includes a fire hydrant box 1, and the fire hydrant box 1 includes a box body 11, a door 12, a fire hose 13, joints 14 fixedly arranged at both ends of the fire hose 13, a fire hose 15 and a fire hose The bolt head 16 and the inner wall of the box body 11 are fixedly provided with a mounting seat 2, and the mounting seat 2 is hinged with a mounting arm 3 that can rotate in a horizontal plane.

[0042] Such as figure 1 , 2 As shown, the end of the mounting arm 3 away from the mounting base 2 is rotated and provided with a winding roller 31 for winding the fire hose 13, the winding roller 31 is perpendicular to the mounting arm 3, and the winding roller 31 is fixed on the end close to the mounting arm 3 A limit plate 311 is provided, on which a fixed rod 3111 parallel to the take-up roller 31 is fixed, and on the limit plate 311 a pressing roller 5 parallel to the take-up roller 31 is rotatably arranged.

[00...

Embodiment 2

[0054] A fire extinguishing method, comprising the following steps: performing a fire extinguishing operation through a fire extinguishing system according to any one of claims 1-8;

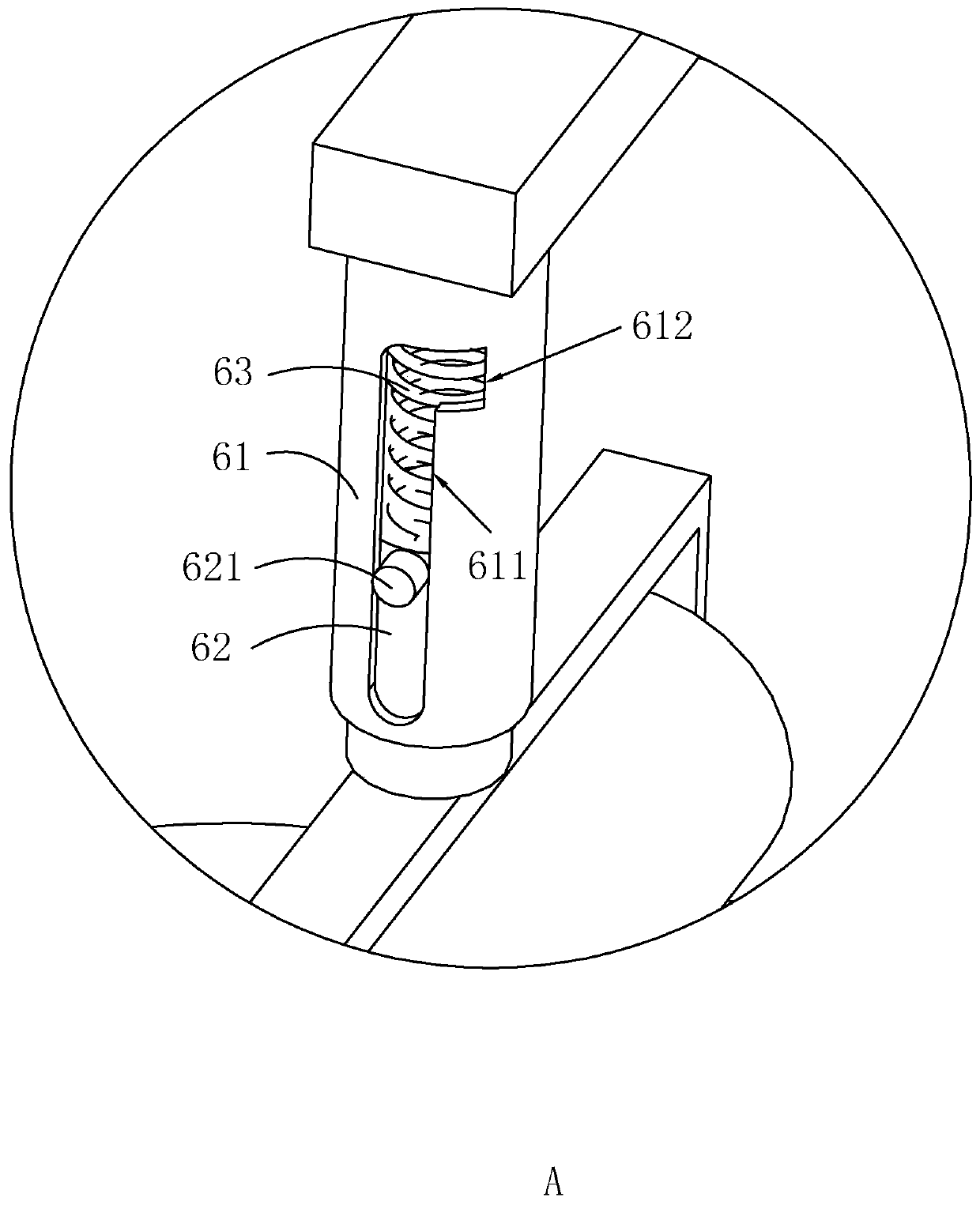

[0055] S1, open the box door 12, turn the installation arm 3, make the installation arm 3 perpendicular to the box body 11, release the limitation of the abutment assembly on the pressure roller 5, and make the pressure roller 5 separate from the fire hose 13, so that the fire hose 13 can Pull out smoothly;

[0056] S2. Connect one joint 14 of the fire hose 13 with the fire hydrant head 16, and connect the other joint 14 with the fire hose 15, pull the fire hose 13, and pull the fire hose 15 to the fire place;

[0057] S3, open the valve on the fire hydrant head 16, you can spray water to extinguish the fire;

[0058] S4. After the fire extinguishing is completed, close the valve of the fire hydrant head 16, remove the fire hose 13 and the fire hose 15, fold the middle of the fire hose 13 in hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com