Efficient washing filter plate and filtering and washing method thereof

A filter plate and plate washing technology, which is applied in the directions of filtration and separation, separation methods, chemical instruments and methods, etc., to achieve the effects of short feeding time, high filtration and washing efficiency, and improved filtration and washing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

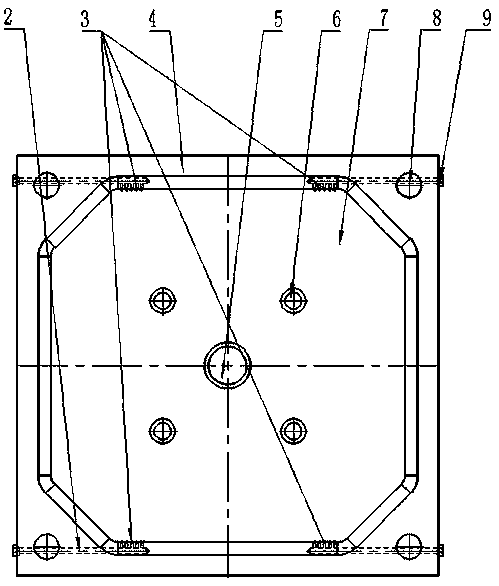

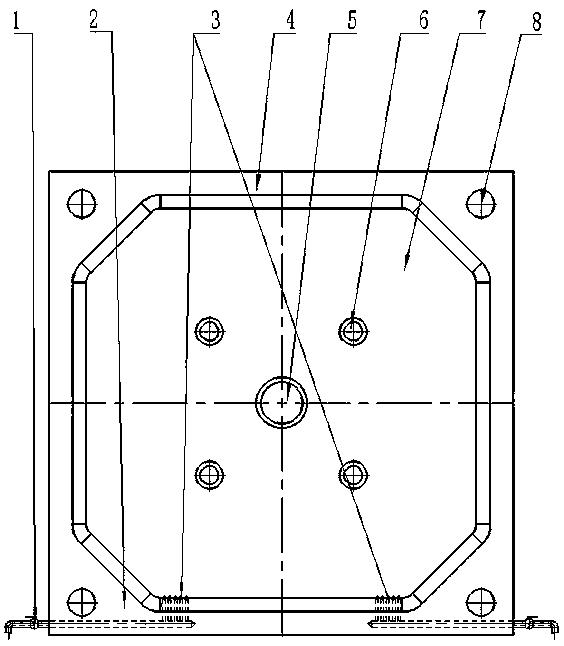

[0017] A high-efficiency washing filter plate, which is composed of the innovatively designed washing plate 13 and the blind washing half of the blind plate 12. It is commonly known as the blind washing half filter plate. Integrated filtration and washing, light and dark double flow, two-way washing function. The washing plate 13 has a washing function, and is mainly provided with a liquid outlet confluence channel 2, a filtrate outlet hole 3, a filter plate sealing edge 4, a filter plate feeding hole 5, a filter plate support point 6, a filter plate filter surface 7, a filter plate Plate four-corner holes 8, filter plate plugs 9; it is characterized in that the lower two corners of the existing washing plate are improved into dark flow holes; Changing to the four-corner undercurrent form avoids the need to manually close the open flow nozzle before washing, and simplifies the manual operation, which is conducive to improving the automation level of the filter press. The blin...

Embodiment 2

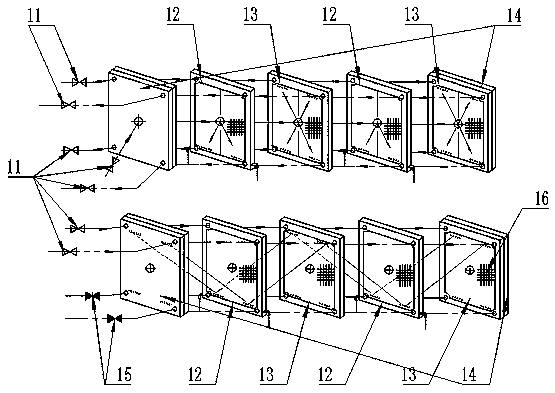

[0020] A filtering and washing method for high-efficiency washing filter plates uses the integrated filtering and washing mechanism formed by the high-efficiency washing filter plates of the present invention. Closing valve 15, filter cloth 16, etc.; the washing method is two-way cross washing, and the liquid outlet method is innovated as an efficient light and dark double outflow form. image 3 The schematic diagram of the washing method (process flow) of the high-efficiency washing filter plate is described.

[0021] When feeding (static filtration), all valves 11 are opened, open flow and dark flow are double effluents, and the feed hole 5 is pumped into the slurry with a high-pressure pump for low-pressure static filtration. The filter cake is formed in the chamber; the filtrate converges to the liquid outlet channel 2 through the filtrate outlet hole 3, and then flows out from the four corner holes 8 on the washing plate 13, or it can also converge to the liquid outlet ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com