UV curing device and curing process thereof

A technology for curing equipment and workpieces, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of limited luminous efficiency of UVC lamp beads, insufficient illuminance, and low efficiency, and achieve curing. The effect of good effect, high illuminance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

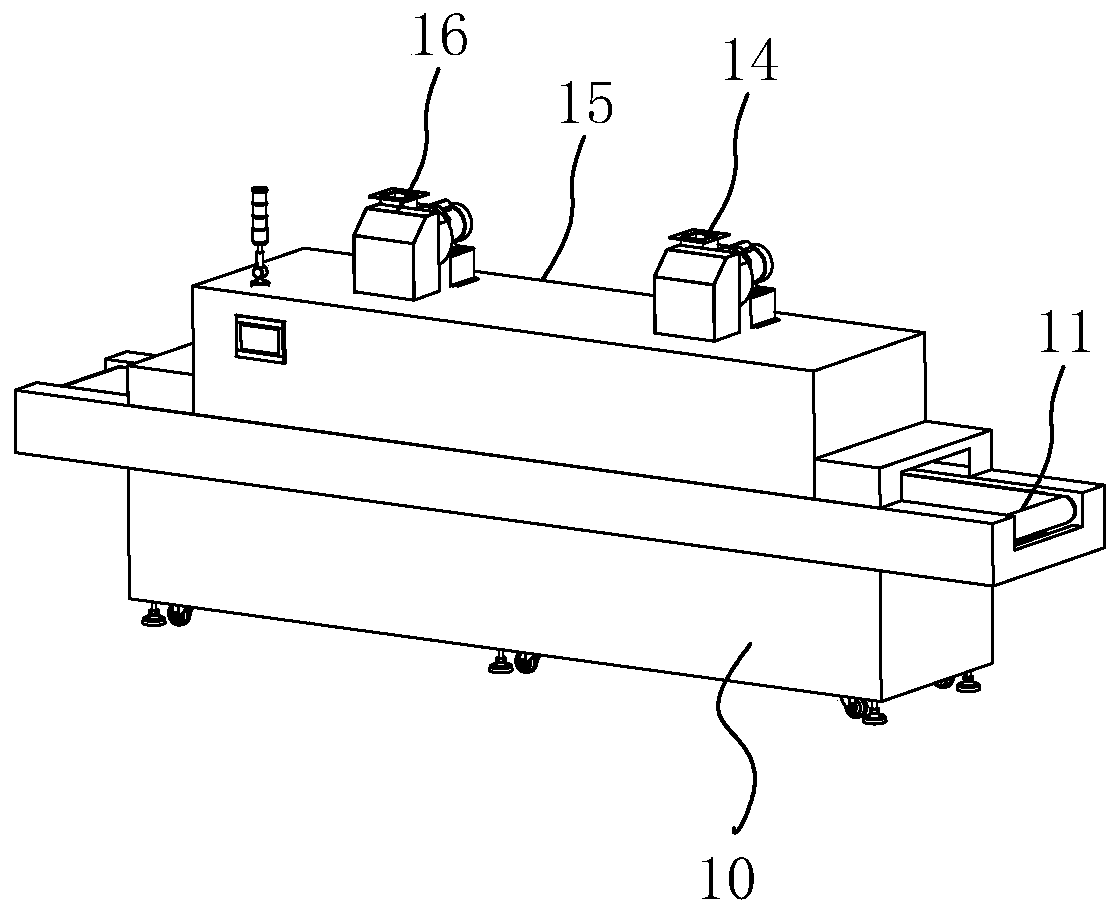

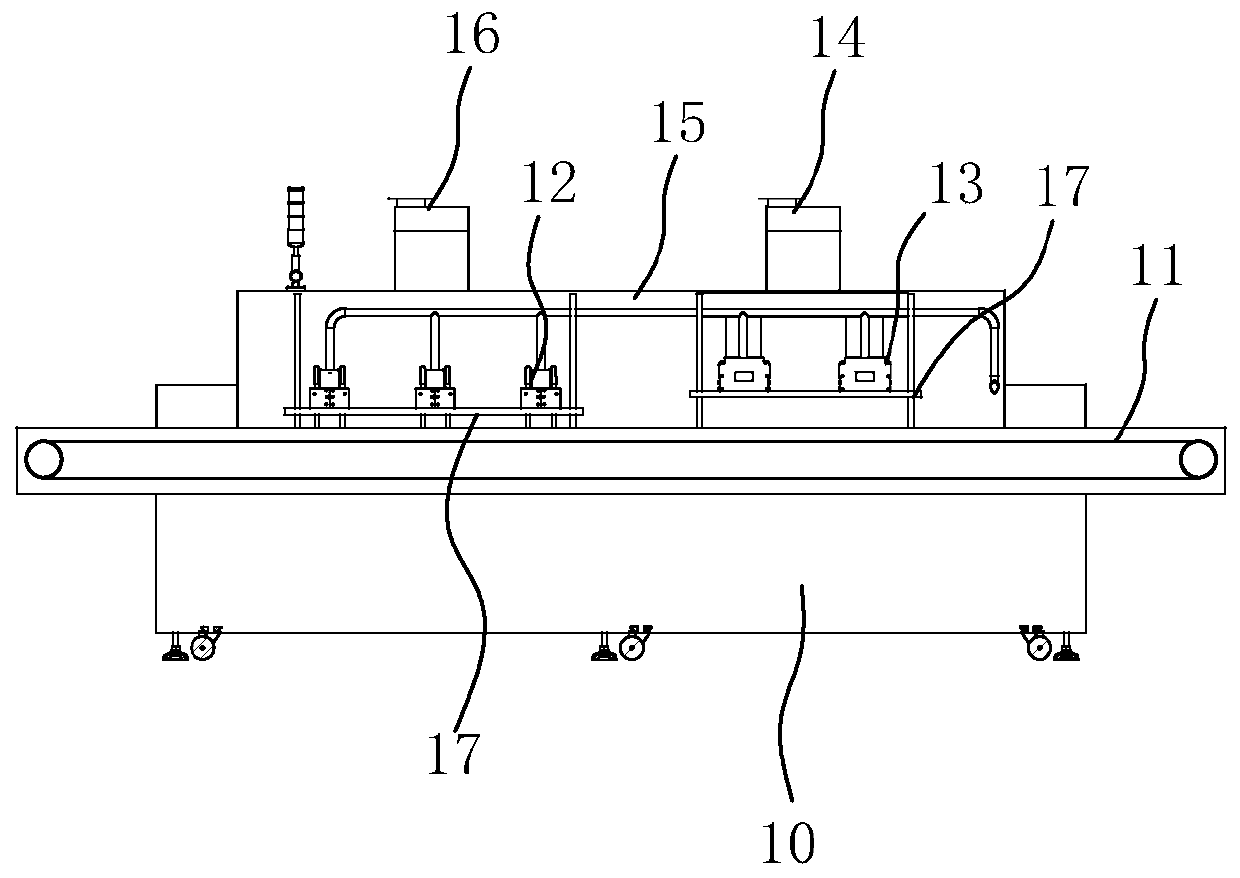

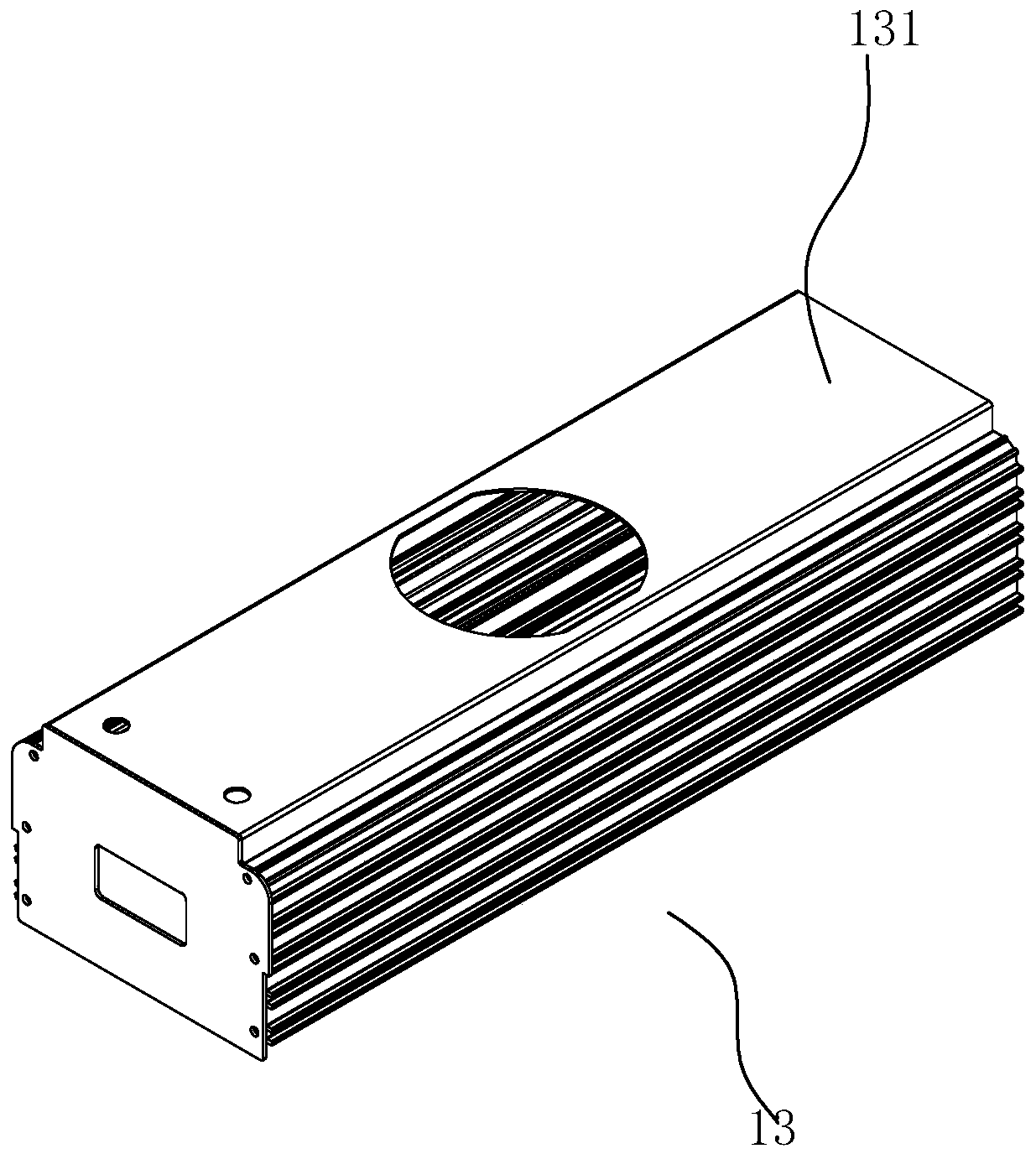

[0022] like Figure 1 to Figure 4 Drawings of embodiments of the invention.

[0023] A UV curing device such as figure 1 , 2 As shown, it includes a mounting frame 10 , a conveyor belt 11 mounted on the mounting frame 10 , and several groups of UVLED light sources 12 positioned on the upper side of the conveyor belt 11 . Several groups of UVC light sources 13 are also provided on the upper side of the conveyor belt 11 . The UVC light source 13 is located at the rear side of the UVLED light source 12 in the moving direction of the conveyor belt 11 . The UVLED light source 12 is arranged at the feed end of the conveyor belt 11 , and the UVC light source 13 is arranged at the discharge end of the conveyor belt 11 . The workpiece mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap