Vector spraying and quenching device suitable for complex-shaped part

A technology of quenching device and complex shape, which is applied in the direction of quenching device, heat treatment equipment, manufacturing tools, etc. It can solve the problems that hinder the production work of spray cooling of complex parts, so as to avoid deformation and excessive residual stress, rapid cooling, and uniform spraying shower effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

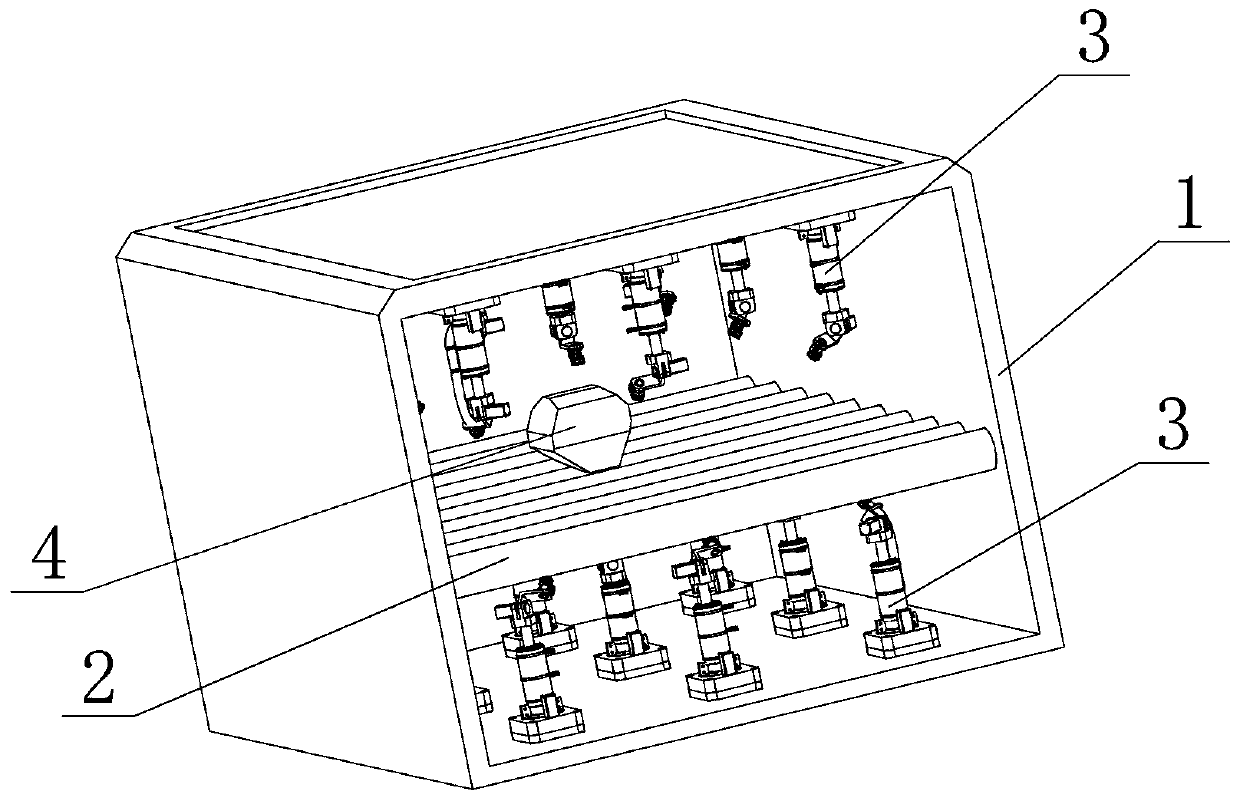

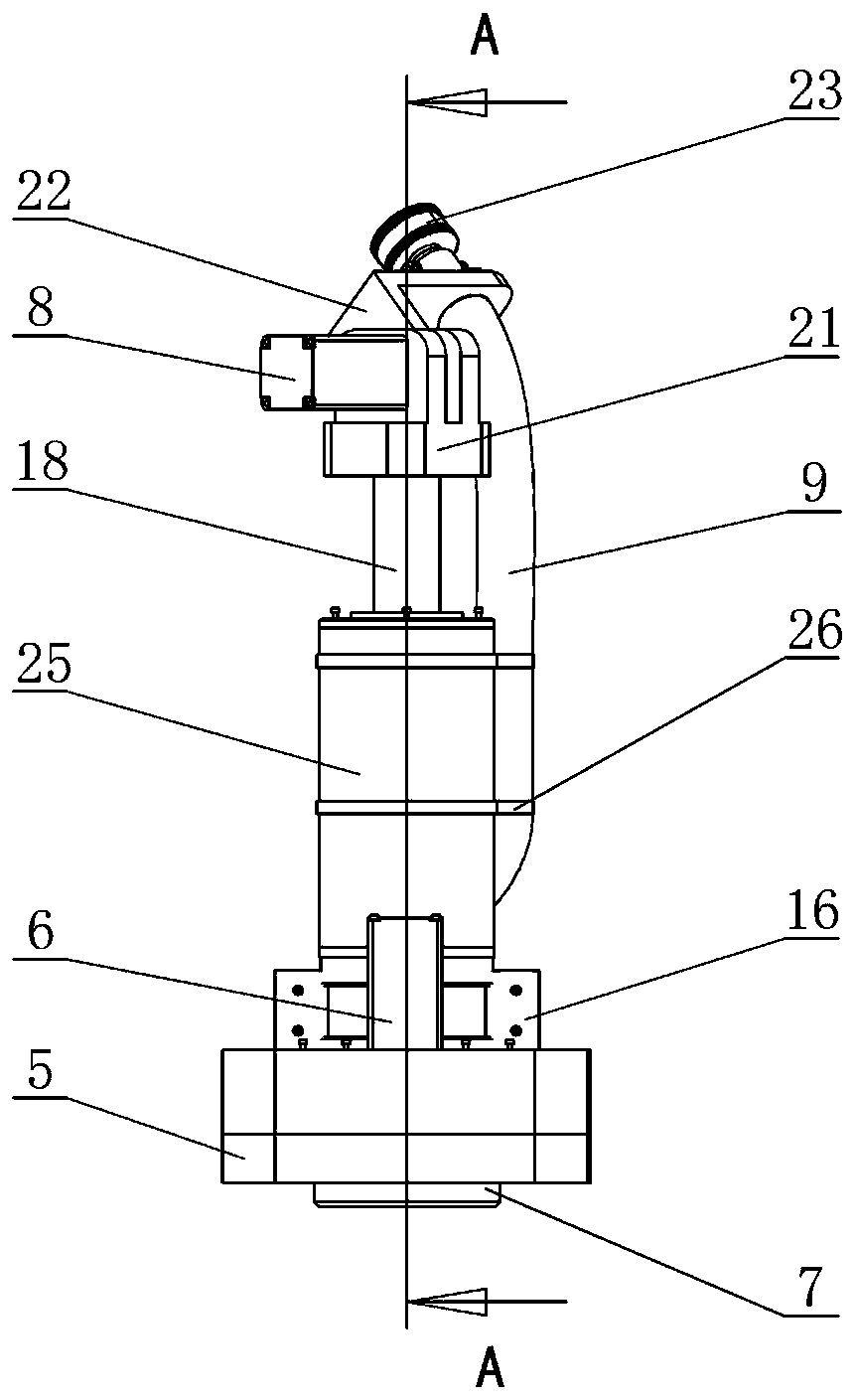

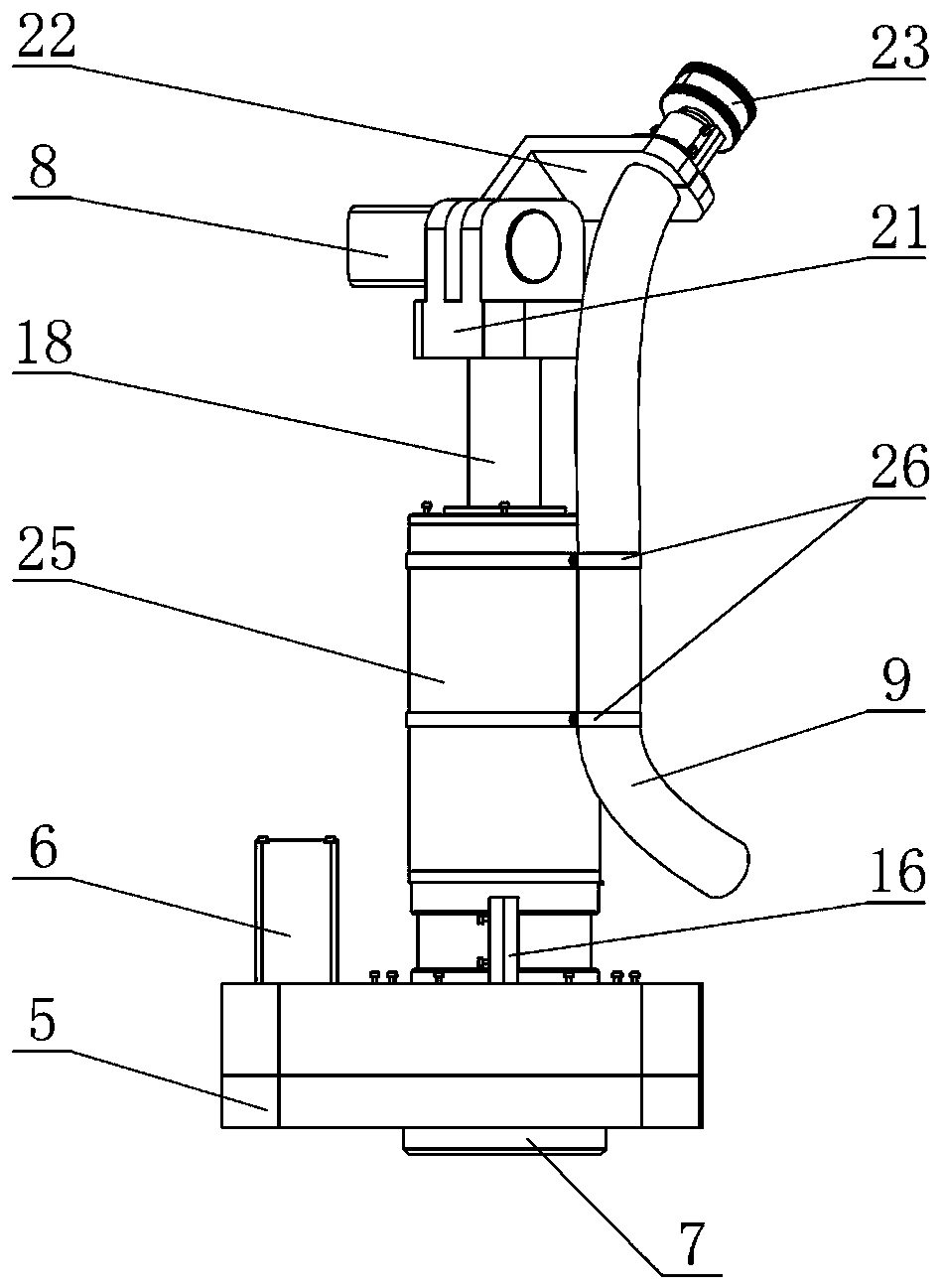

[0026] Such as figure 1 As shown, the structure diagram of the vector spray quenching device of the present invention is provided, which is composed of a quenching furnace box 1, a transmission roller 2 and a vector shower 3, the inside of the quenching furnace box 1 is a cavity, and the transmission roller The number of 2 is multiple, and a plurality of transmission rollers 2 are arranged in parallel in the inner cavity of the quenching furnace box 1, and the polyhedral part 4 to be quenched is placed on the transmission roller 2, and the transmission roller 2 rotates the polyhedron part 4 Conveys to central location for spray quenching. The number of vector showers 3 shown is multiple, which are respectively arranged above and below the transmission roller 2, the nozzle 23 of the vector shower 3 above the transmission roller 2 is located at the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com