Prefabricated bay window unit components, prefabricated bay window and construction method

A construction method and bay window technology, applied in building construction, construction, building material processing, etc., can solve the problems of complex operation, difficult to control the quality of connection points, prefabricated bay windows can not be used as air conditioning panels, etc. The effect of convenient installation, simple structure and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

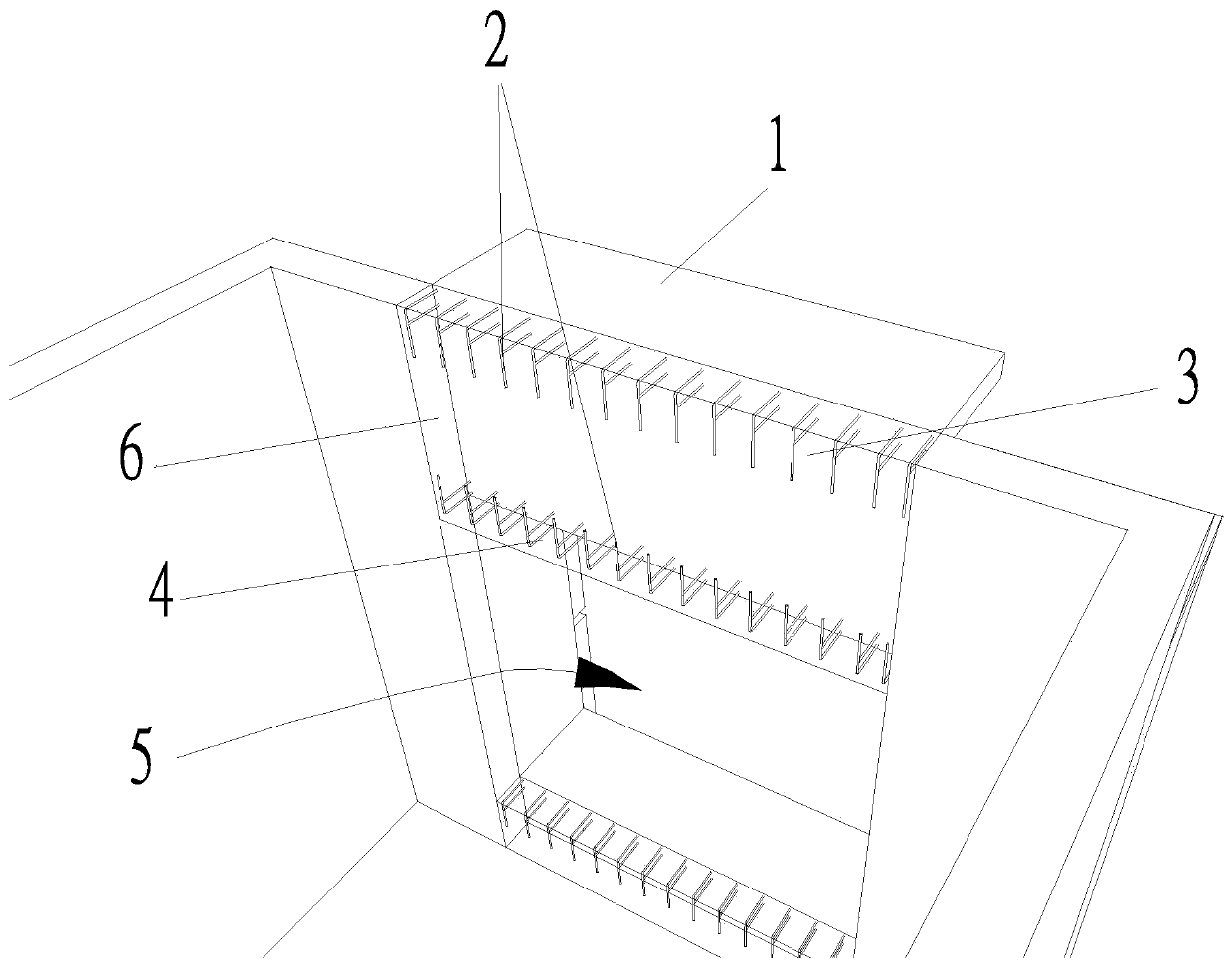

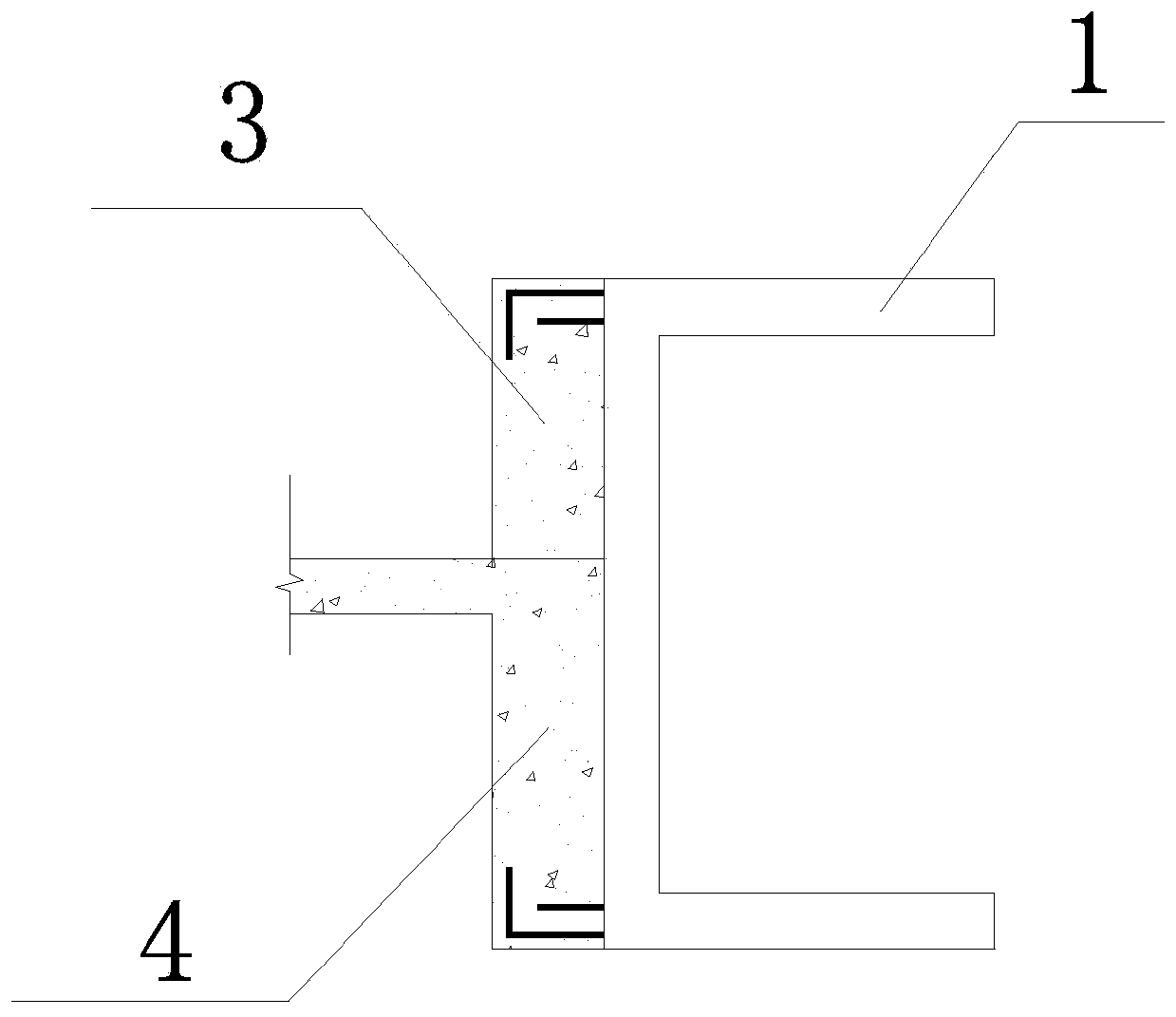

[0032] Such as figure 2 and Figure 4 As shown, the prefabricated bay window of this embodiment includes two prefabricated bay window unit components 1, wherein one prefabricated bay window unit member 1 is fixed to the upper cast-in-place beam 4 through anchors 2, and the other prefabricated bay window unit member 1 A bay window space 5 is formed between two prefabricated bay window unit components 1 by fixing the anchor piece 2 with the cast-in-place beam 4 on the lower floor.

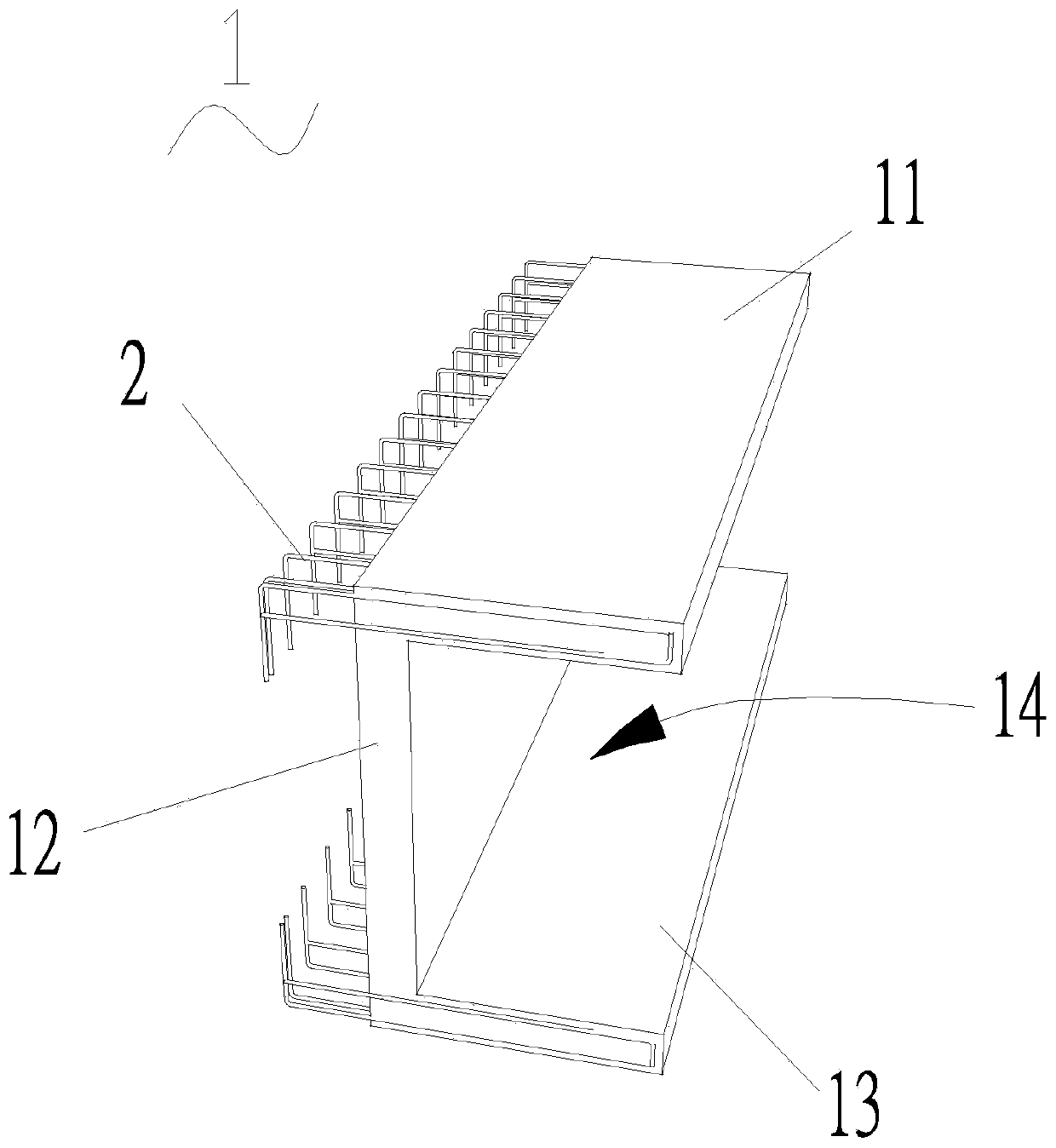

[0033] Such as figure 1 As shown, the prefabricated bay window unit component 1 of this embodiment includes a top plate 11, a side plate 12 and a bottom plate 13, the top plate 11, the side plate 12 and the bottom plate 13 are enclosed to form a C-shaped groove 14 that can accommodate an air conditioner external unit, and the top plate 11 An anchor piece 2 extending outward from the C-shaped groove 14 is pre-embedded on the base plate 13 . In this embodiment, the anchor piece 2 is a steel bar. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com