Rice flour drying transmission speed control method and transmission device

A transmission device and technology for rice noodles, applied in drying, dryer, progressive dryer and other directions, can solve the problems of small drying process, enhanced production cost of rice noodles, expensive near-infrared equipment, etc., to reduce processing cost, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

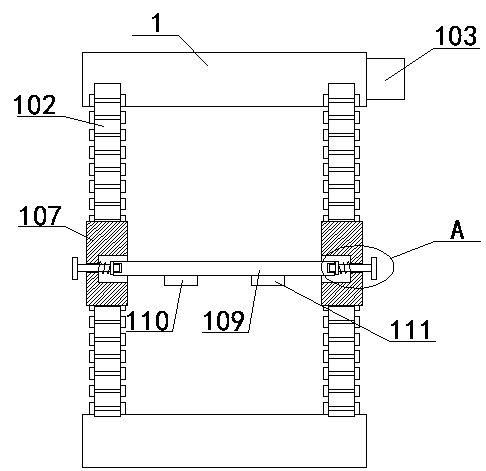

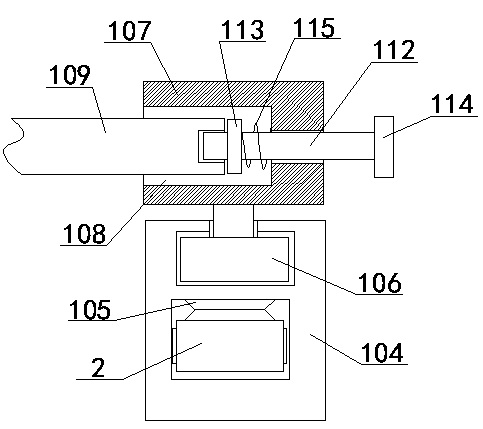

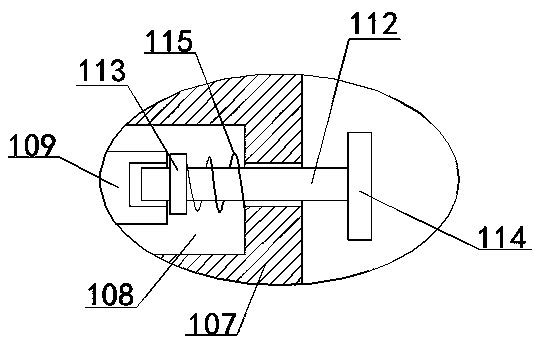

[0042] refer to Figure 1-4 , a transmission device for drying rice noodles, comprising a transmission mechanism 1 and a control mechanism, the output end of the control mechanism is connected to the input end of the transmission mechanism 1, and is used to control the transmission mechanism 1;

[0043] The transmission mechanism 1 includes a support base 101 and two symmetrically arranged transmission chains 102 for driving the installation block 104 to move, and one end of the support base 101 is fixedly connected with a transmission motor 103 for driving the transmission chain 102 to rotate, and the output of the transmission motor 103 End is connected with the input end of transmission chain 102;

[0044] The transmission chain 102 is sleeved with two symmetrically arranged mounting blocks 104 for supporting the support block 107. The mounting block 104 is provided with a port corresponding to the transmission chain 102, and the corresponding gear teeth of the transmission...

Embodiment 2

[0060] refer to Figure 1-4 , a transmission device for drying rice noodles, comprising a transmission mechanism 1 and a control mechanism, the output end of the control mechanism is connected to the input end of the transmission mechanism 1, and is used to control the transmission mechanism 1;

[0061] The transmission mechanism 1 includes a support base 101 and two symmetrically arranged transmission chains 102, which are used to drive the installation block 104 to move. One end of the support base 101 is fixedly connected with a transmission motor 103, and the transmission motor 103 is provided with a frequency converter for controlling the transmission. The rotating speed of motor 103 is controlled, and the output end of frequency converter is connected with the input end of signal transmission module, is used to drive transmission chain 102 to rotate, and the output end of transmission motor 103 is connected with the input end of transmission chain 102;

[0062] The trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com