Device and method for testing shear strength of layered composite plate material

A plate shearing and layered compounding technology, which is applied in the direction of measuring device, using stable shearing force to test material strength and strength characteristics, can solve the problem of limited sample length, inaccurate measurement, shape and noise test accuracy, etc. problem, to achieve the effect of reducing the probability of inaccurate measurement, easy to polish, and easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described with embodiment below in conjunction with accompanying drawing:

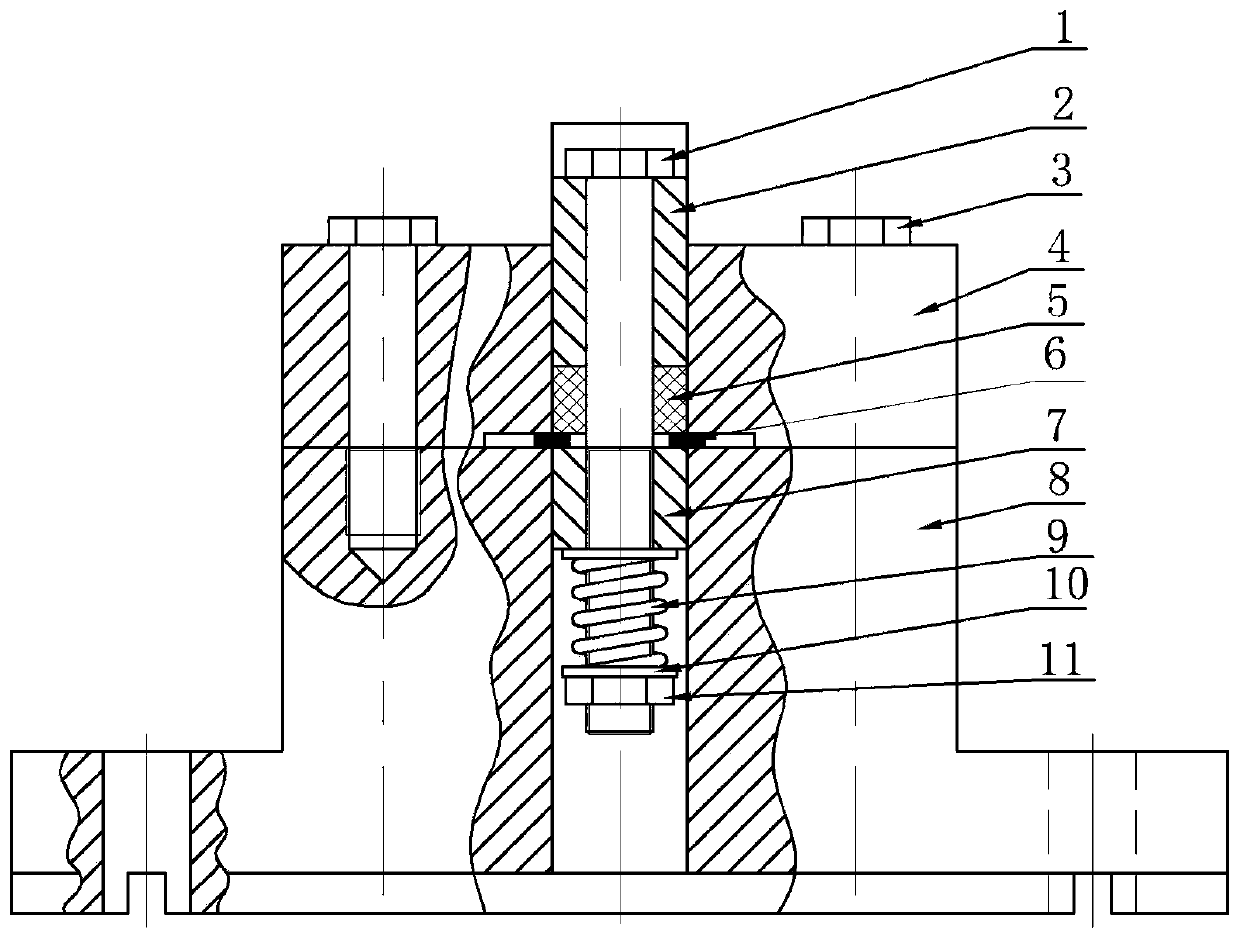

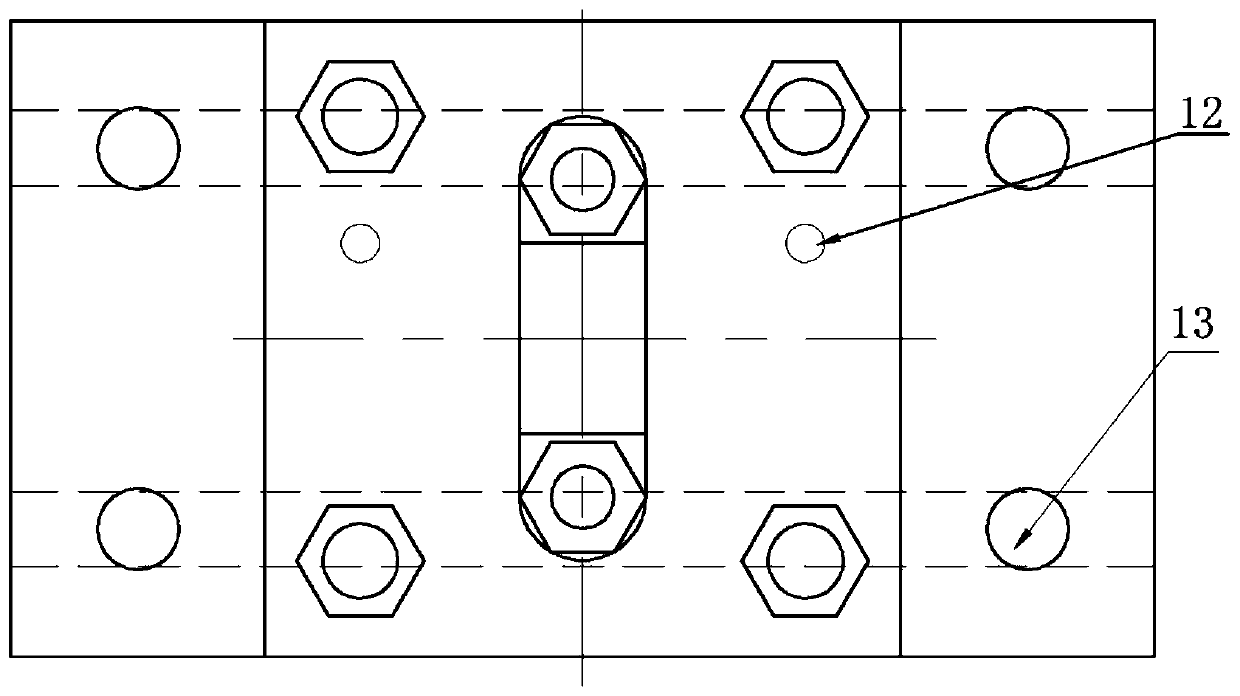

[0030] Such as figure 1 As shown in -5, the shear strength test device for layered metal composite panels includes: die fastening bolt 1, punch carrier 2, mold body fastening bolt 3, upper die 4, punch 5, sample 6, gland 7 , Lower die 8, fastening spring 9, gasket 10, die fastening nut 11, positioning pin 12, lower die fastening bolt hole 13.

[0031] There are two bolt holes on the gland 7, the gland 7 is placed under the punch 5, two bolt holes are processed on the punch 5, two bolt holes are passed between the gland 7, the punch 5 and the punch carrier 2 The positioning pins are aligned, and the cladding side of the metal composite plate sample to be tested is clamped between the gland 7 and the punch 5, and the die fastening bolt 1 and the die are used to tighten the gap between the gland 7, the punch 5 and the punch carrier 2. The fastening nut 11 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com