Touch display module and electronic equipment

A touch display and touch technology, which is applied in electrical digital data processing, character and pattern recognition, instruments, etc., can solve the problems of light energy loss, reduce the success rate of fingerprint recognition under the screen, etc., and achieve high sensitivity and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the touch display module and electronic equipment provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

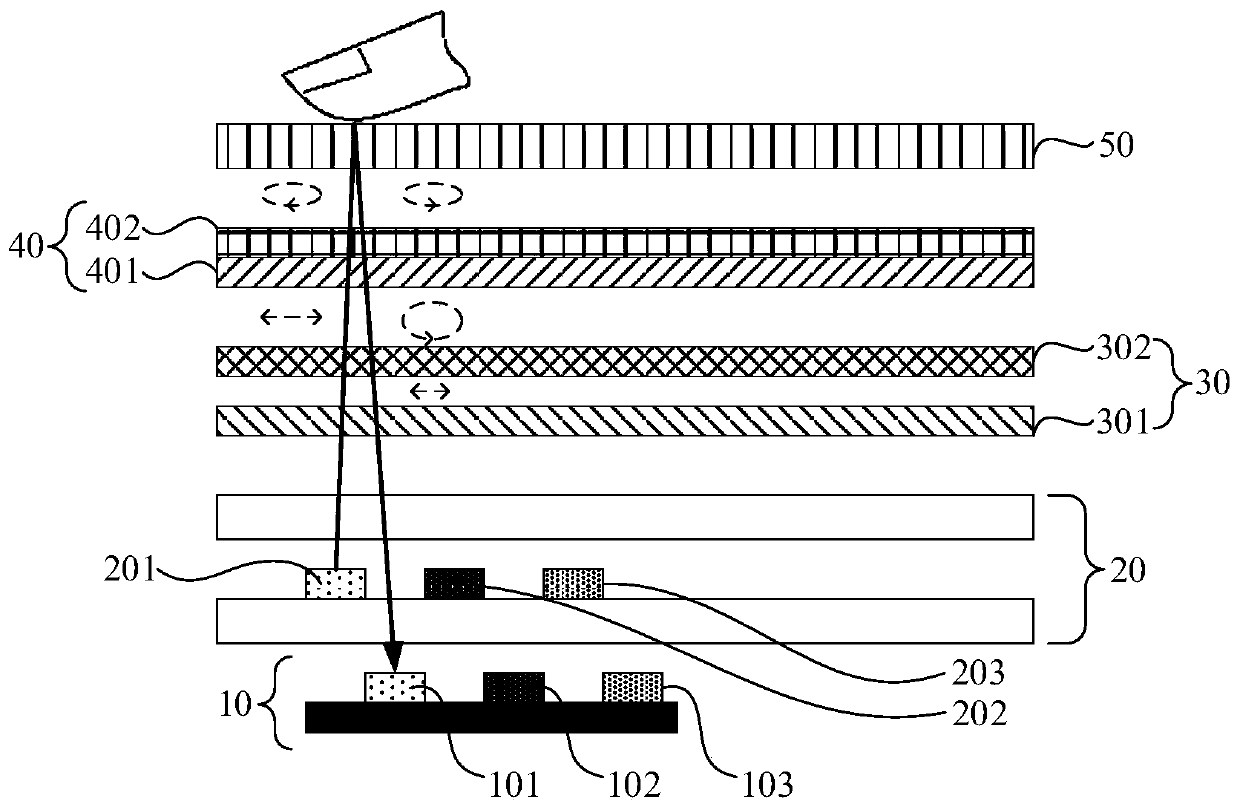

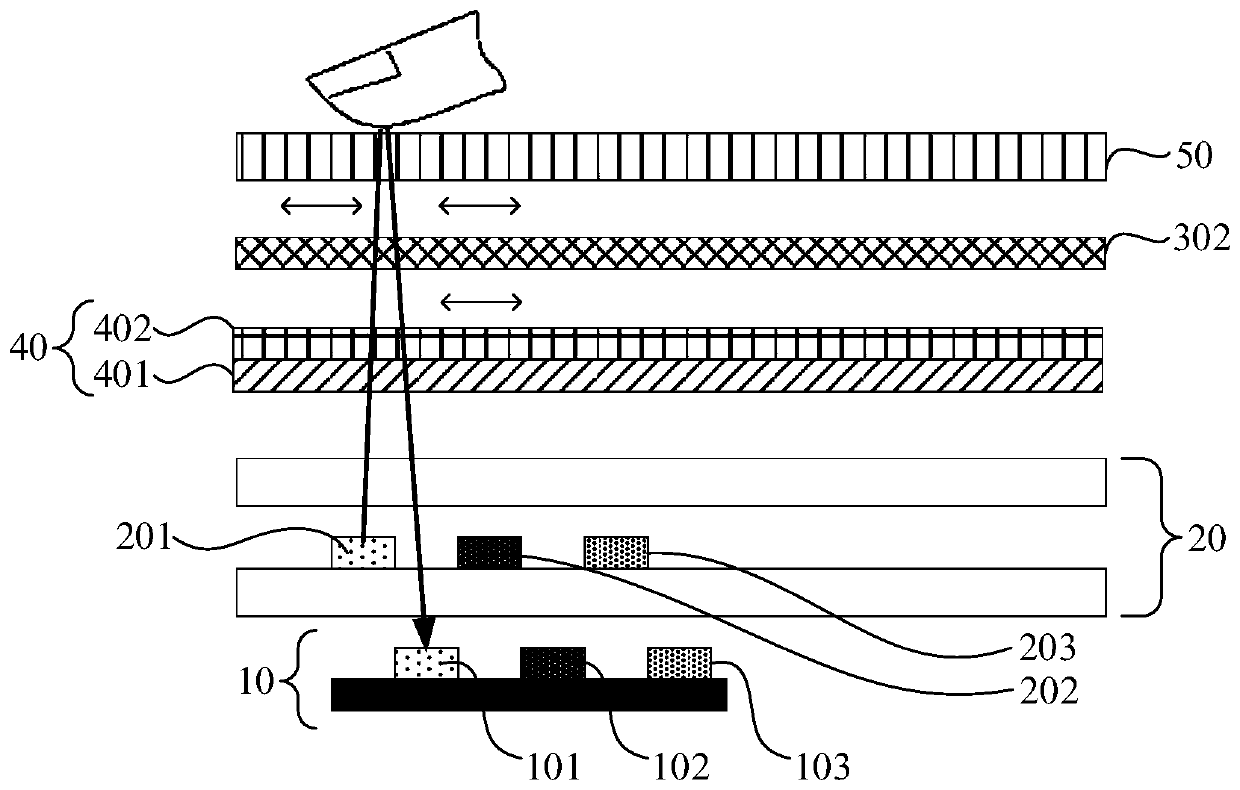

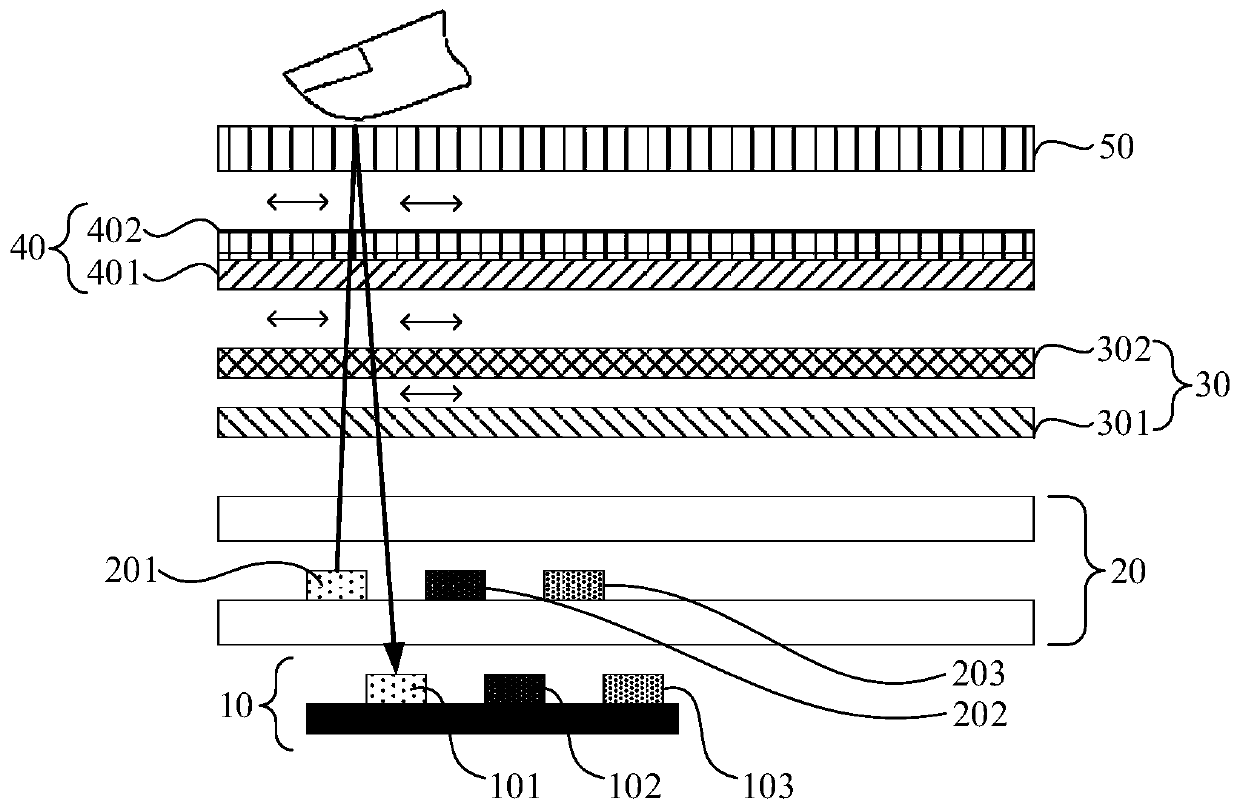

[0034] like figure 1 As shown, in the related art, the optical under-display fingerprint identification system includes a fingerprint identification module 10, a display panel 20, a polarizing structure 30 (including a 1 / 4 wave plate 301 and a linear polarizing plate 302), The touch substrate 40 and the cover 50 , wherein the fingerprint recognition module 10 is located on the non-light emitting side of the display panel 20 , and the polarizing structure 30 , the touch substrate 40 and the cover 50 are located on the light emitting side of the display panel 20 .

[0035] When the above-mentioned optical under-screen fingerprint identification system performs fingerprint identification, the light-emitting unit in the display panel 20 is used as a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com