LED display screen defect detection method

A technology for display screen and defect detection, applied in static indicators, instruments, etc., can solve the problems of low detection efficiency of LED display screen, incompatibility of large LED screen detection, blurred vision affecting employees' health, etc., to avoid employee health problems, Achieve the effect of eliminating and avoiding missed inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

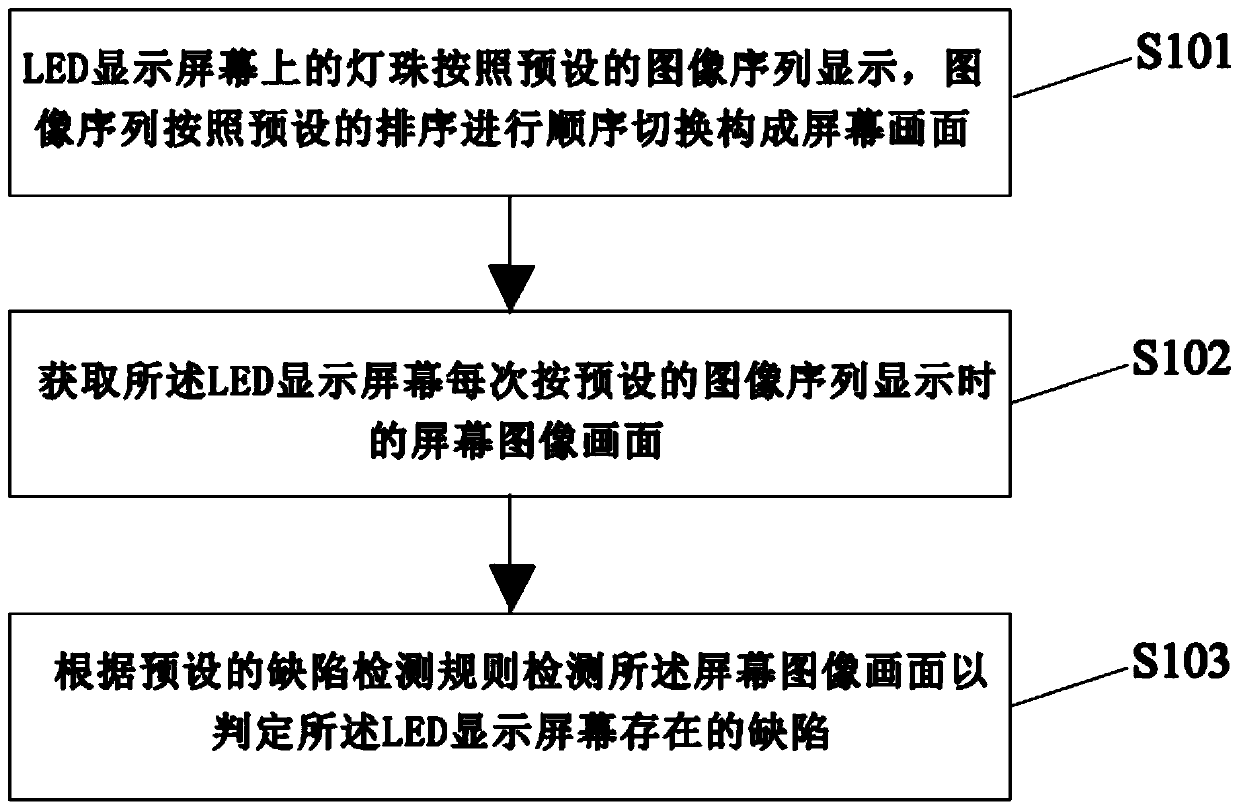

[0035] Power on the large-scale LED display screen, control the lamp beads on the LED display screen to display according to the preset image sequence, and the image sequence is sequentially switched according to the preset order to form a screen picture. In this embodiment, in order to comprehensively detect the LED display The LED bead defect of the screen, the image sequence is an array of arithmetic progressions, in which the elements in the array are the serial numbers of the LED lamp beads that are normally illuminated, and the elements that are not in the array are the serial numbers of the LED lamp beads that are not illuminated, including two types, one is The difference is an arithmetic sequence of zero, and the screen picture formed when the LED display screen is displayed is a monochromatic full-screen image, and the full-screen image includes a red full-screen image, a green full-screen image, a blue full-screen image, and a white full-screen image; one is a differe...

specific Embodiment 2

[0044] The difference between this embodiment and specific embodiment 1 is that this embodiment adopts serial control logic for detection, that is, 16 different image sequences are based on switching→detection→switching→detection→...→switching→detection, each Once the image is switched, the industrial camera is controlled to capture the current large-scale LED screen image, and then the image is inspected for defects. If the current image is detected to be qualified, the next image sequence will be switched and inspected; if the current image is detected to be unqualified, it will be stopped. Subsequent image sequence switching and detection tasks directly determine that the current large LED screen is a defective product.

specific Embodiment 3

[0046] The difference from Embodiment 1 or Embodiment 2 is that this embodiment calculates the pixel feature for the position of each LED light bead in the screen image.

[0047] Such as Figure 4 As shown, the LED display screen defect detection method of the present embodiment, the method includes the following steps:

[0048] S201: The lamp beads on the LED display screen are displayed according to a preset image sequence, and the image sequence is sequentially switched according to a preset sequence to form a screen image;

[0049] S202: Obtain the screen image picture of the LED display screen each time it is displayed according to a preset image sequence;

[0050] S203: Calculate the pixel feature of each LED lamp bead position in the screen image,

[0051] Specifically, according to the theory of digital image processing, an image is composed of pixels, and the unit of a pixel is pixel, which represents the minimum feature of a digital image. Each pixel has a gray va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com