Nano cuprous oxide/silk fibroin complex and preparation method thereof

A technology of nano-cuprous oxide and silk fibroin, applied in the field of nano-materials, can solve problems such as affecting performance, uneven dispersion of cuprous oxide, easy oxidation of cuprous oxide, etc., achieving low cost, easy industrial production, strong The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

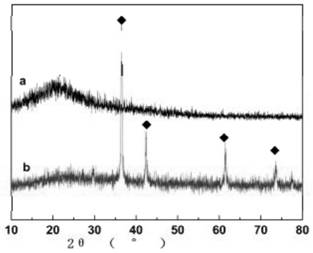

Method used

Image

Examples

Embodiment 1

[0028] First add 100 grams of cocoons to 1 liter of 0.5w / v% Na 2 CO 3 In the aqueous solution, boil for 30min, repeat the treatment three times, fully wash with distilled water, put it in a drying oven at 45°C after washing, and dry to obtain degummed silk fibers; 2 :C 2 h 5 OH:H 2 The molar ratio of O=1:2:8 is used to prepare a ternary solvent, and the silk fiber is hydrolyzed at a constant temperature in a water bath at 70° C. for 1 hour at a bath ratio of 1:10 to obtain a completely dissolved brownish-yellow silk fiber hydrolysis solution; Put the hydrolyzed solution into a dialysis bag, dialyze with distilled water for 72 hours, put the dialyzed silk fiber hydrolyzed solution into -80°C for 12 hours, and then freeze-dry it at -58°C until dry to obtain white, loose porous, spongy Silk fibroin: Compared with the existing commercially available silk fibroin, the silk fibroin prepared by the above steps of the present invention has the advantages of uniform molecular weigh...

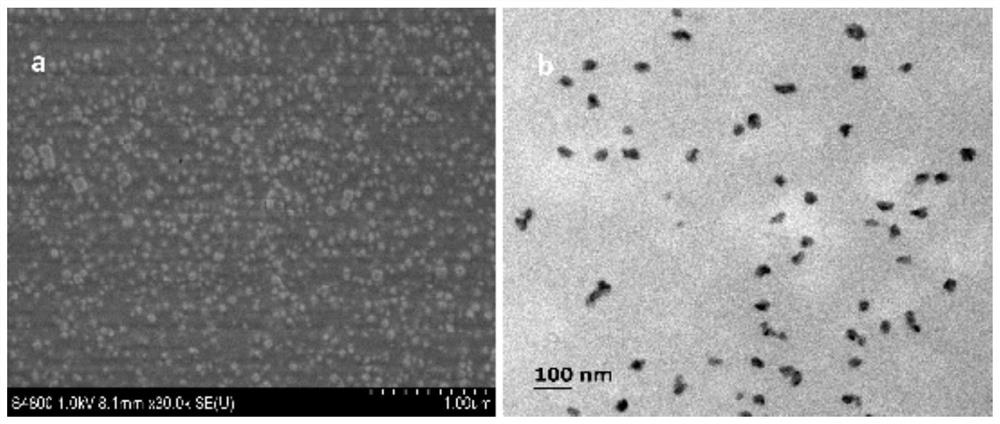

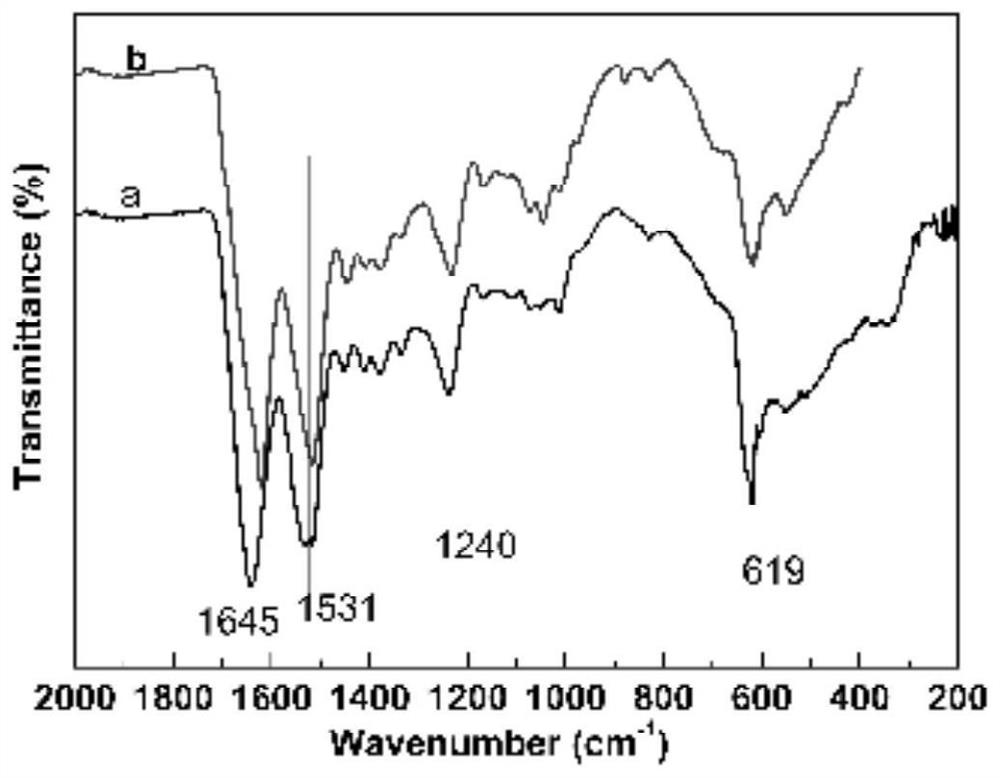

Embodiment 2

[0038] Add 0.2g silk fibroin to 10mL water and stir until completely dissolved to obtain a silk fibroin solution; add 0.08mol.L -1 Add 10mL of copper sulfate solution to the silk fibroin solution and stir evenly, add 0.2mol.L -1 Sodium hydroxide to adjust the pH value to 12, add 0.08mol.L -1 Take 20 mL of vitamin C solution, react at room temperature (25° C.) for 48 hours, dialyze for 3 days, and freeze-dry to obtain nano-cuprous oxide / silk fibroin complex.

Embodiment 3

[0040] Add 0.2g silk fibroin to 10mL water and stir until completely dissolved to obtain a silk fibroin solution. Add 0.04mol.L -1 Add 10mL of copper sulfate solution to the silk fibroin solution and stir evenly, add 0.2mol.L -1 Sodium hydroxide to adjust the pH value to 12, add 0.08mol.L -1 Vitamin C solution, 20mL, reacted at room temperature (25°C) for 48 hours, dialyzed for 3 days, and freeze-dried to obtain nano-cuprous oxide / silk fibroin complex.

[0041] Table 1 below shows the contents of nitrogen, oxygen, carbon and copper elements in the nano-cuprous oxide / silk fibroin composite prepared in different examples from X-ray photoelectron spectroscopy (XPS).

[0042] Table 1 Contents of nitrogen, oxygen, carbon and copper elements in the nano-cuprous oxide / silk fibroin composites prepared in different examples.

[0043] Table 1

[0044]

[0045] The data in the above table shows that with the increase of the concentration of copper sulfate, the content of copper ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com