A horizontal tank lng recondenser

A horizontal tank and condenser technology, which is applied in the field of liquefied natural gas vapor treatment, can solve the problems of strong liquid level fluctuations in vertical tanks, poor vertical structure stability, and single condensation means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

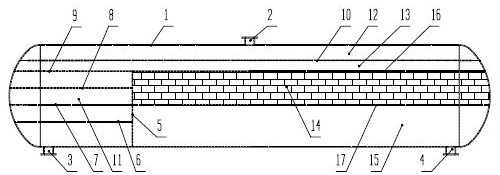

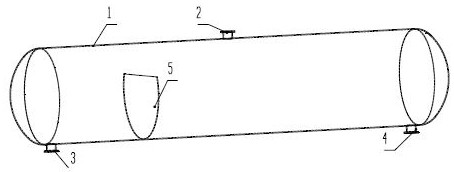

[0030] The structural layout, operation process and innovations of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

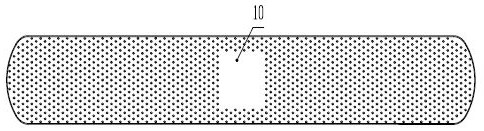

[0031] A horizontal tank LNG recondenser, the horizontal cylinder 1 is composed of a horizontal cylindrical cylinder and sealing heads at both ends thereof. The condensing space mainly includes two parts: BOG pre-cooling space 11 and stuffing condensing space 14. BOG pre-cooling space 11 is a constant liquid level in an overflow state, and the liquid level is located on the upper edge of middle partition 5. The liquid level of stuffing condensing space 14 is The fluctuating liquid level due to the change of processing capacity is about 100-150mm away from the upper edge of the middle partition plate 5; the horizontal cylinder 1 mainly includes the LNG injection plate 10, the BOG baffle plate 6 / 8 with holes at the right end, and the BOG with holes at the left end Baffle plate 7 / 9, inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com