Device for manufacturing cement paste test-piece and application method thereof

A technology for cement slurry and test piece, which is used in measuring devices, preparation and sampling of samples for testing, etc., can solve the problems of high operator's operating level requirements, large influence of processing conditions, and high testing costs, and achieves good sealing performance. , The effect of low detection cost and simple use method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

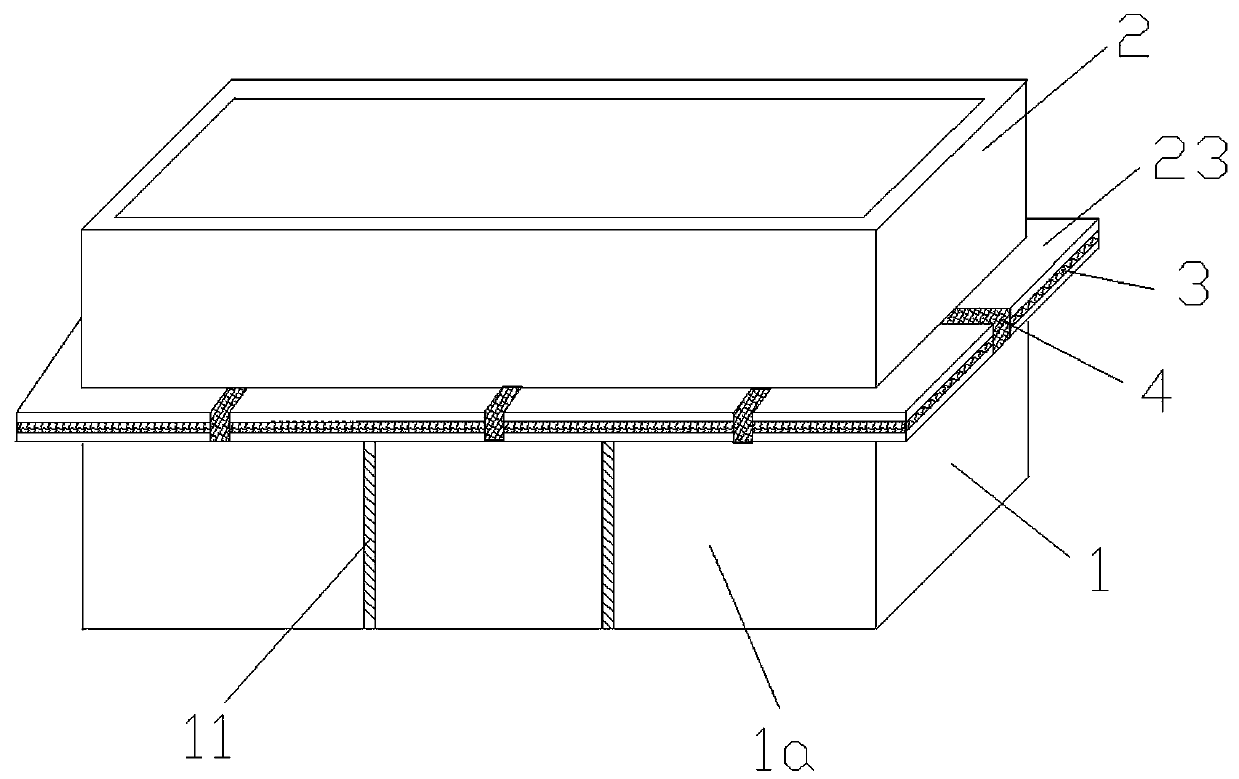

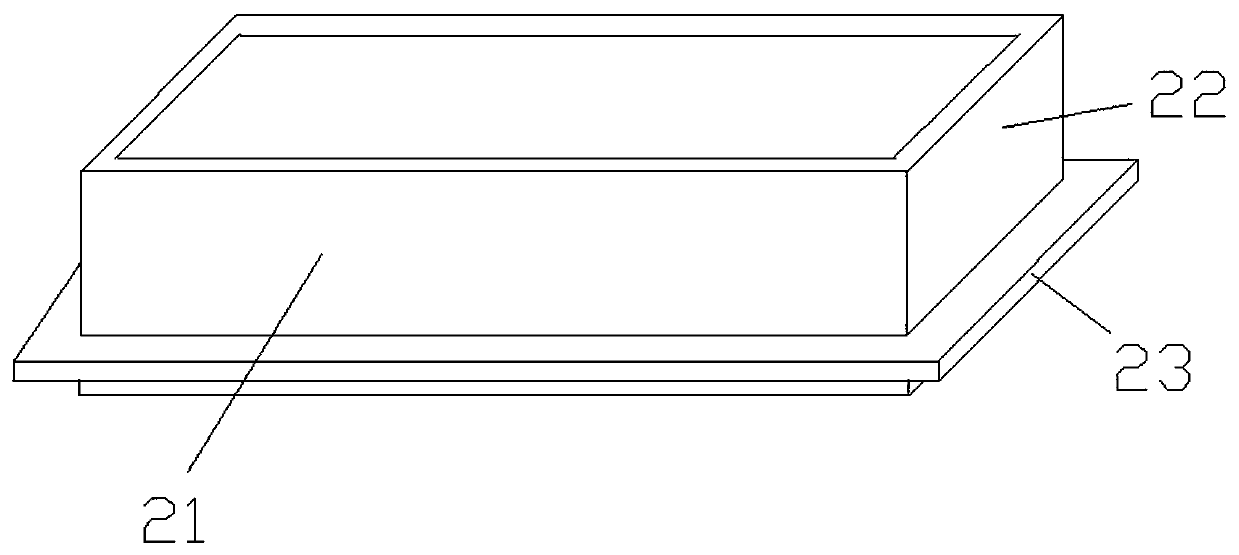

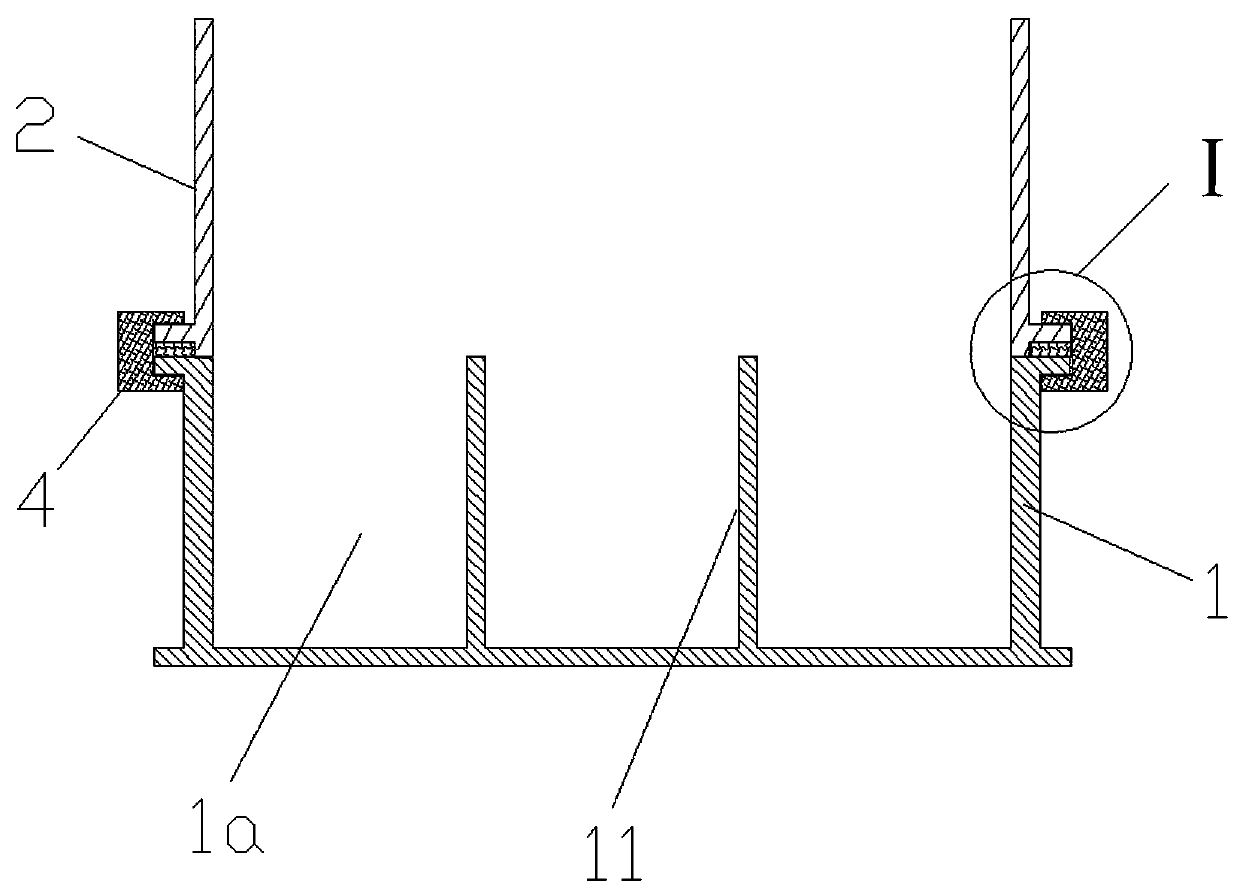

[0033] Figures 1 to 5 It is a structural representation of the present invention.

[0034] The reference signs therein are: bottom mold 1, specimen mold cavity 1a, partition 11, lower fastening plate 13, upper mold 2, long side wall 21, wide side wall 22, upper fastening plate 23 , sealing ring 3, fastener 4.

[0035] As shown in the figure, the present invention discloses a device for making cement slurry test pieces. Three test pieces can be produced at one time by using the device, and the produced test pieces have good integrity and very small dimensional errors, and there is no need to for secondary processing. This device comprises bottom mold 1, and bottom mold 1 is a rectangular box with certain height, length and width, and it has an upper opening. In order to form multiple standard cement slurry specimens at one time without cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com