Tube bus T-connection fittings

A technology for connecting metal fittings and pipe busbars. It is used in busbar installation, multi-conductor connectors, clamping/spring connections, etc. It can solve the problems of poor applicability of fittings, and achieve the effect of improving applicability and anti-corona effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

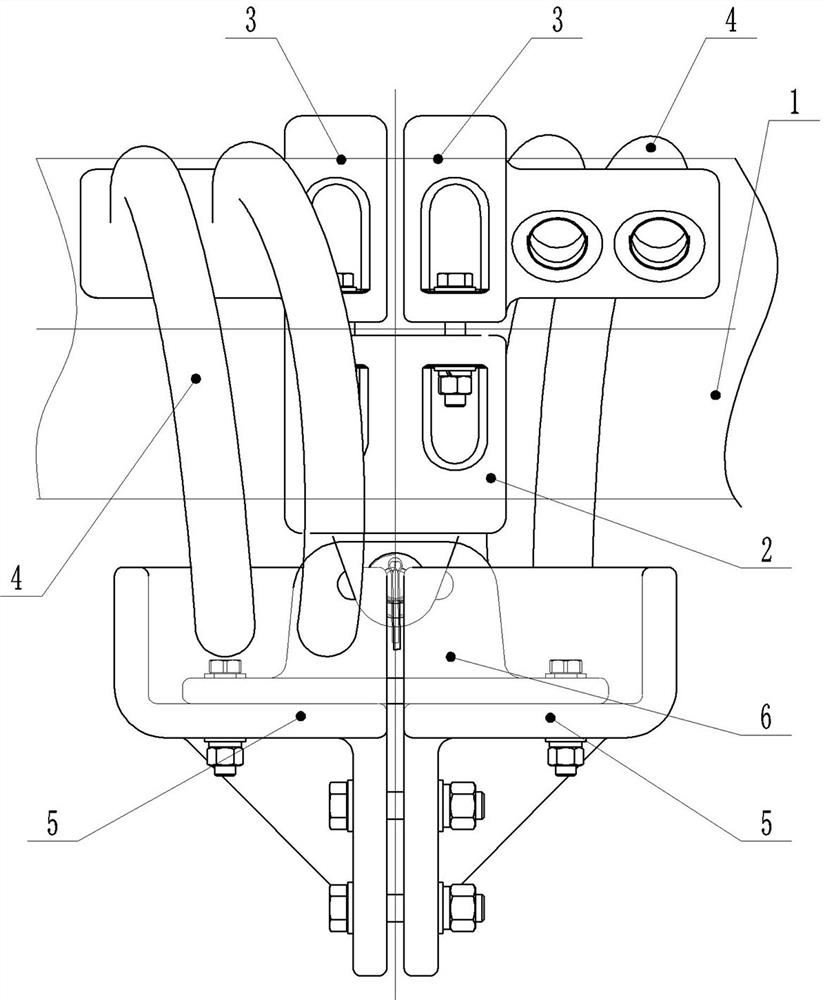

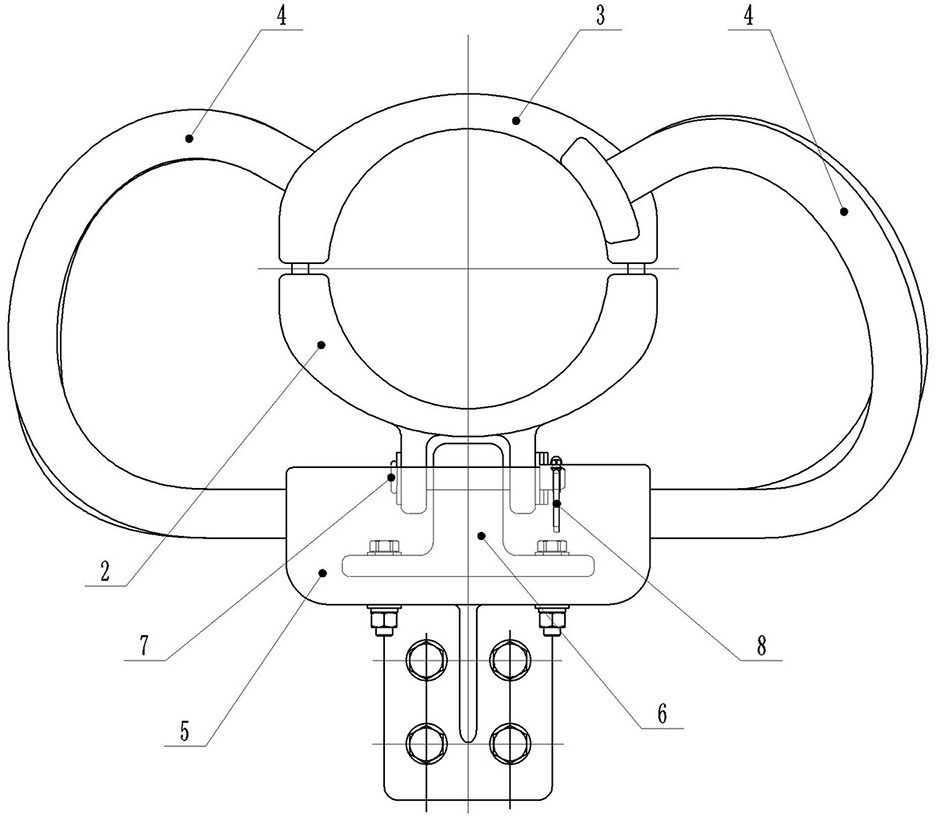

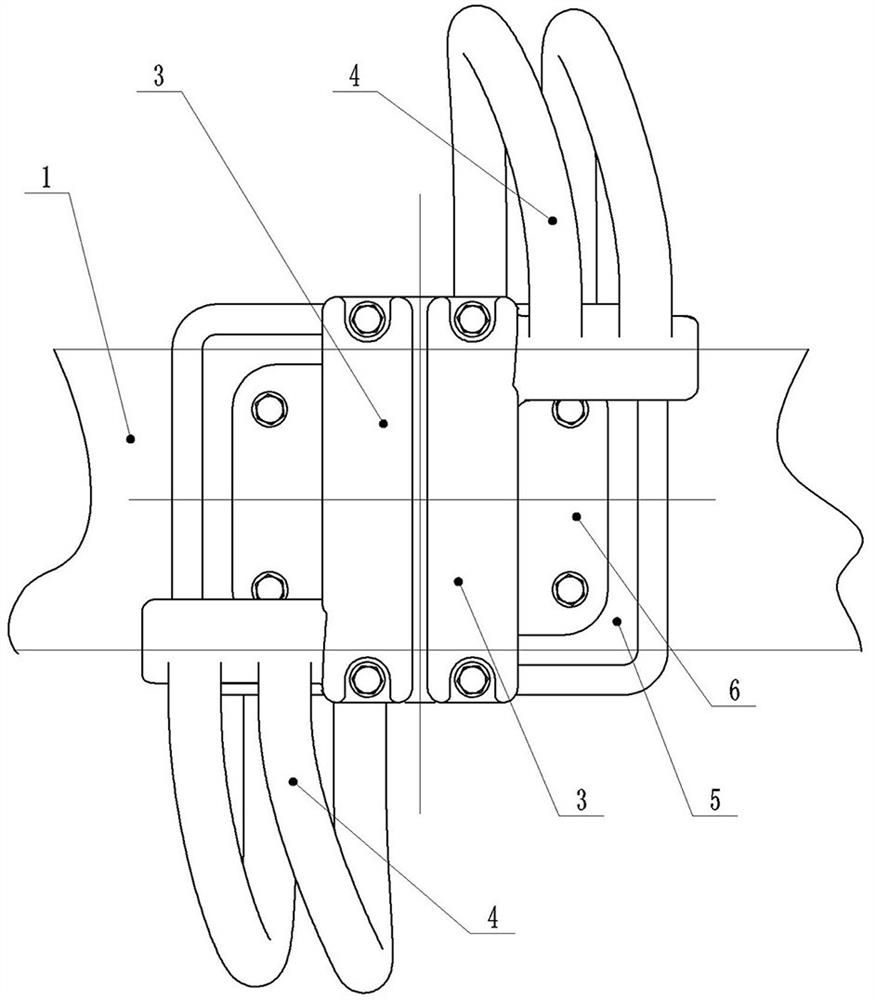

[0050] The embodiments of the T-shaped connection fittings for pipe busbars of the present invention will be further described below in conjunction with the accompanying drawings.

[0051] The embodiment of the T-type connection fittings of the pipe bus bar of the present invention, such as figure 1 , figure 2 and image 3 As shown, the T-type connection fittings for the pipe busbar include a clamp seat and a clamp cover 3 for clamping the pipe busbar 1, and the T-type connection fittings for the pipe busbar also include a fitting seat for supporting and fixing the pipe busbar 1. The bus bar 1 is clamped and electrically connected to the terminal block.

[0052] Such as Figure 4 , Figure 5 and Figure 6 As shown, the fitting seat includes two separate and oppositely arranged fitting supports 5. The fitting support 5 is L-shaped and includes a connecting plate 51 and a drain plate 53. The connecting plate 51 is arranged parallel to the axis of the pipe bus 1, and the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com