Device for covering integrated wall board with aluminum coating

A technology integrating wall and covering device, applied in the direction of lamination device, lamination, layered products, etc., can solve the problems of increasing equipment cost, reducing production efficiency, increasing process, etc., to achieve the effect of efficient guiding and pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

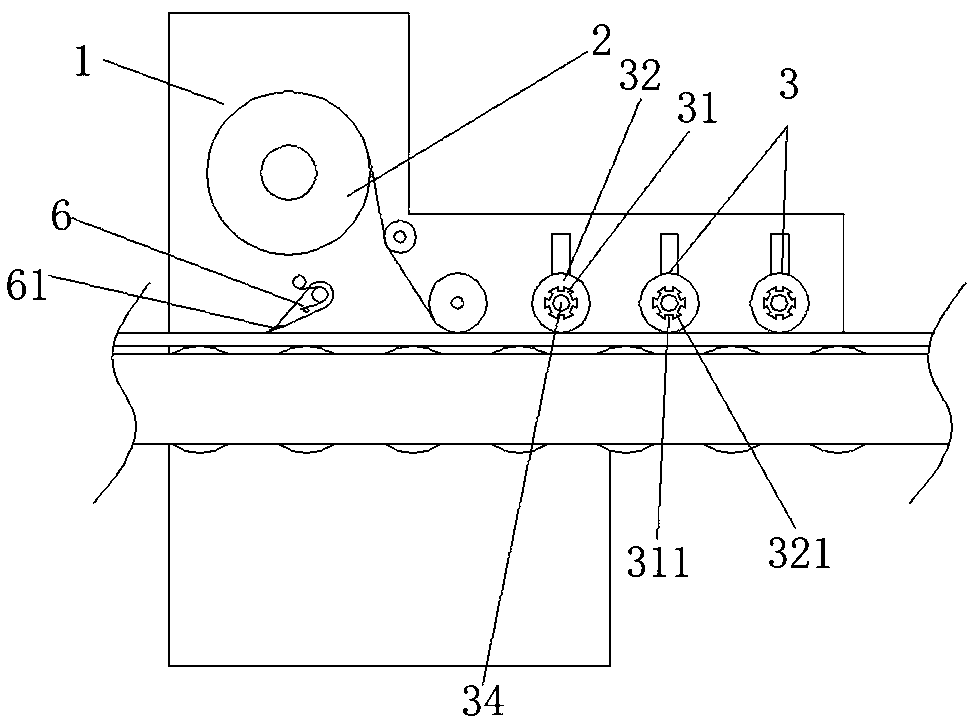

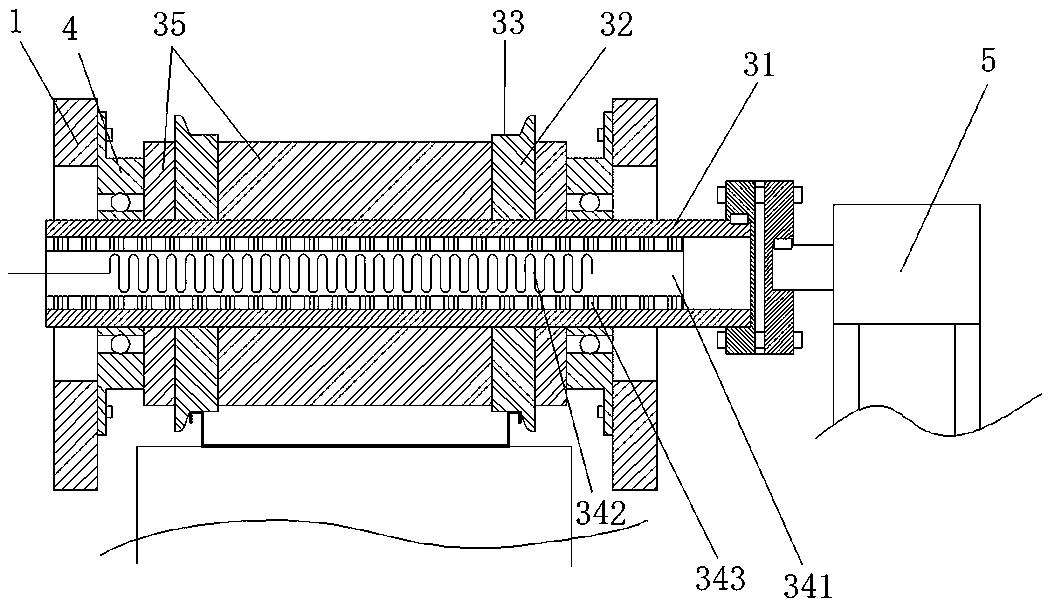

[0025] Such as figure 1 , 2 An aluminum cladding covering device for integrated wall panels is shown, including an unwinder 2 straddling the integrated wall panel production line through a bracket 1, and the unwinder 2 is a common unwinding device used in general film production. The device also includes a pressing roller 3 located on the downstream side of the unwinder 2. The pressing roller 3 includes a base shaft 31 and a pressing ring 32 sleeved on the base shaft 31. A heating core 34 is pierced in the base shaft 31. The outer surface of the pressing ring 32 is circumferentially provided with a pressing groove 33 for pressing the aluminum foil and heat sealing it to the integrated wall panel. When working, the integrated wall panel that enters the aluminum cladding covering device of the integrated wall panel has been bent and grooved in a U-shaped shape, and the two sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com