A kind of deep ultraviolet phosphate glass and its preparation method and application

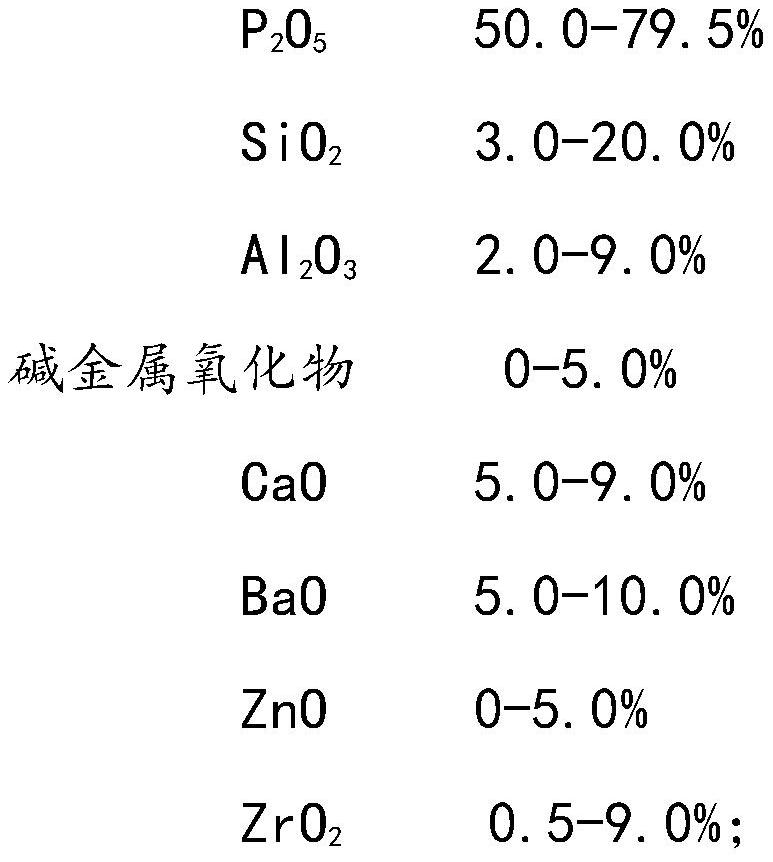

A technology of phosphate glass and deep penetration, which is applied in the field of special glass materials and its preparation, and can solve the problems that the transmittance cannot meet the requirements of deep ultraviolet detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

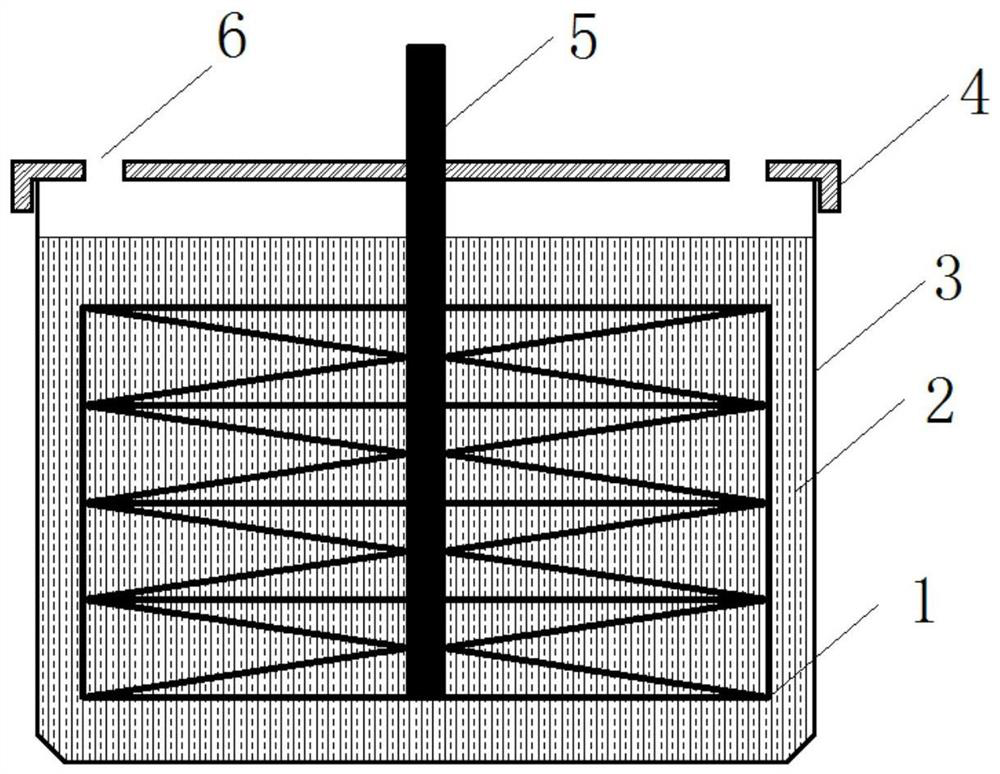

Image

Examples

preparation example Construction

[0052] The present invention also provides a method for preparing the above-mentioned deep ultraviolet phosphate glass, comprising the following steps:

[0053] (1) Iron removal and conversion: The raw materials are subjected to iron removal treatment, and then the high-purity raw materials are proportioned according to the designed components. According to the weight percentage of each component, the corresponding raw material weights are converted to obtain the corresponding raw material weights, and then the raw materials are weighed. Mix to obtain mixed powder;

[0054] In the present invention, the main raw materials are subjected to iron removal treatment to improve the purity of glass raw materials, strictly control the batching utensils, and avoid introducing new impurities in the process, and the materials such as measuring tools and containers used in the batching operation should be made of aluminum, and the mixing machine Containers and storage batches are all made...

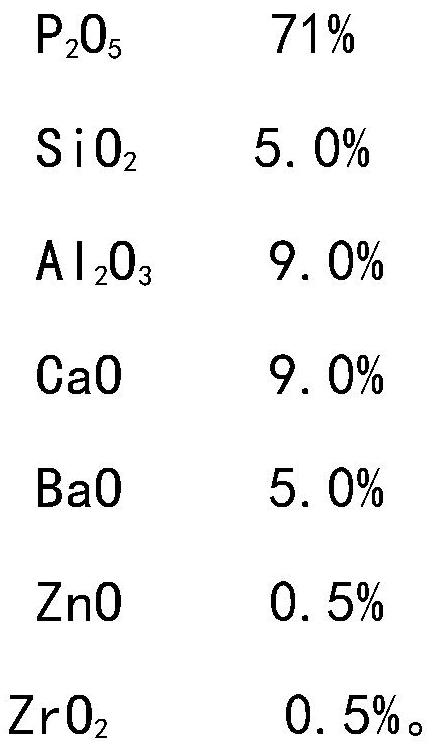

Embodiment 1

[0076] First, select the glass raw material according to the glass composition of Example 1 in Table 1, and carry out iron removal treatment to improve the purity of the glass raw material with the main raw materials in the glass raw material, and the oxides of variable valence elements such as Fe 2 o 3 etc. are strictly controlled, and the finished glass Fe 2 o 3 The content is less than 1PPm, the high-purity quartz sand (Fe 2 o 3 Content less than 1PPm), high-purity phosphoric acid, aluminum acetate (analytical pure) mixed evenly, and then add alkali metal to introduce raw material sodium carbonate (analytical pure) to mix, so as to avoid chemical reaction during mixing, and the prepared batch should not be placed If the time is too long, the feeding operation should be carried out as soon as possible to avoid the reaction between phosphoric acid and raw materials to cause agglomeration. Phosphoric acid volatilizes a lot. In order to ensure that the prepared glass is bas...

Embodiment 2

[0078] Refer to Example 2 in Table 1 for the actual composition of the glass, use the same raw materials and raw material requirements as in Example 1, and heat in a glass melting furnace with a pre-melting temperature of 700 °C for 80 minutes, and then continue to heat up at a heating rate of 5 °C / min to 1350°C, melting process system for 4 hours, and select the heat-resistant steel mold preheated to 550°C to pour into the specified test product and the same test conditions as in Example 1, the basic properties of the sample are shown in Table 1. performance. (1) The UV light transmittance reaches 81.4% at a wavelength of 254nm; (2) The average linear expansion coefficient at 30-300°C is 52.1×10 -7 / °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com