A kind of polyamide reverse osmosis composite membrane and preparation method thereof

A technology of reverse osmosis composite membrane and polyamide, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem that the water permeability and salt removal rate cannot reach the ideal level, the rejection rate is not ideal, and the process is cumbersome To achieve the effect of increasing retention rate and flux, improving chemical resistance stability, and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

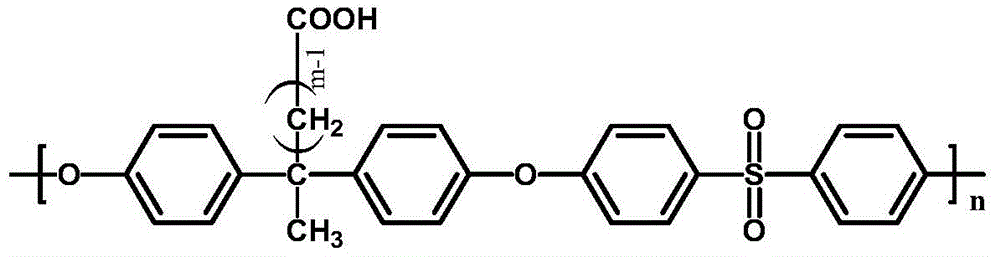

[0045]Dissolve polysulfone and polyarylethersulfone with pendant carboxyl groups (structural formula 1) in DMF, defoam and filter to prepare casting solution. Among them, the content of polysulfone in the casting solution is 16wt%, and the type and amount of polyarylethersulfone with side carboxyl groups are shown in Table 1. Then, the reverse osmosis composite membrane was prepared by the same porous support layer preparation process as in the comparative example. The test conditions were the same as those of the comparative example, and the results are shown in Table 1.

Embodiment 5-7

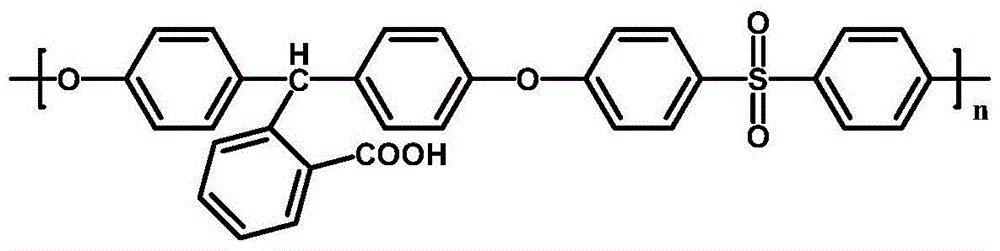

[0047] Polyethersulfone and polyarylethersulfone with side carboxyl groups (structural formula 2) were dissolved in DMF, defoamed and filtered to prepare the casting solution. Among them, the content of polysulfone in the casting solution is 16wt%, and the type and amount of polyarylethersulfone with side carboxyl groups are shown in Table 1. Then, the reverse osmosis composite membrane was prepared by the same porous support layer preparation process as in the comparative example. The test conditions were the same as those of the comparative example, and the results are shown in Table 1.

Embodiment 8-10

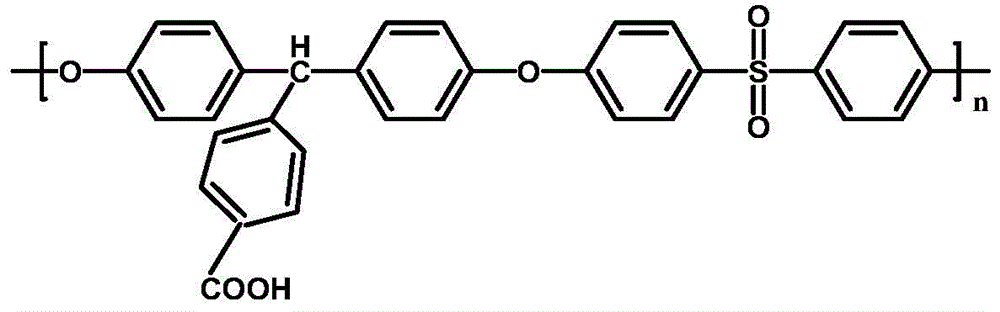

[0049] Polysulfone and polyarylethersulfone with pendant carboxyl groups (structural formula 4) were dissolved in DMF, defoamed and filtered to prepare the casting solution. Among them, the content of polysulfone in the casting solution is 16wt%, and the type and amount of polyarylethersulfone with side carboxyl groups are shown in Table 1. Then, the reverse osmosis composite membrane was prepared by the same porous support layer preparation process as in the comparative example. The test conditions were the same as those of the comparative example, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com