Intercalation composite material and preparation method thereof, polymer nanocomposite material

A nano-composite material and composite material technology, applied in the field of intercalated composite material and its preparation, polymer nano-composite material, can solve the problems of low heat resistance, reduced composite material performance, easy degradation, etc., and achieve chemical resistance stability. Unique, improved dielectric properties, high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides a method for preparing the above-mentioned intercalation composite material, comprising: reacting the inorganic layered material and the fluorocarbon surfactant in water to obtain the intercalation composite material; the inorganic layered material is positively charged layered materials or negatively charged inorganic layered materials; the fluorocarbon surfactant is an anionic fluorocarbon surfactant or a cationic fluorocarbon surfactant.

[0059] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available. The inorganic layered material and the fluorocarbon surfactant are the same as those described above, and will not be repeated here.

[0060] Reacting the inorganic layered material and the fluorocarbon surfactant in water, wherein the mass ratio of the inorganic layered material to the fluorocarbon surfactant is preferably 1:(0.5-20), more preferably 1:(1-1...

Embodiment 1

[0087] Add 500g of water, 1g of layered magnesium aluminum hydroxide and 3g of fluorocarbon surfactant potassium perfluorooctane sulfonate to the reaction vessel in sequence, react at 40°C for 24h, filter, and vacuum dry at 80°C to obtain a fluorocarbon intercalation layer magnesium aluminum hydroxide.

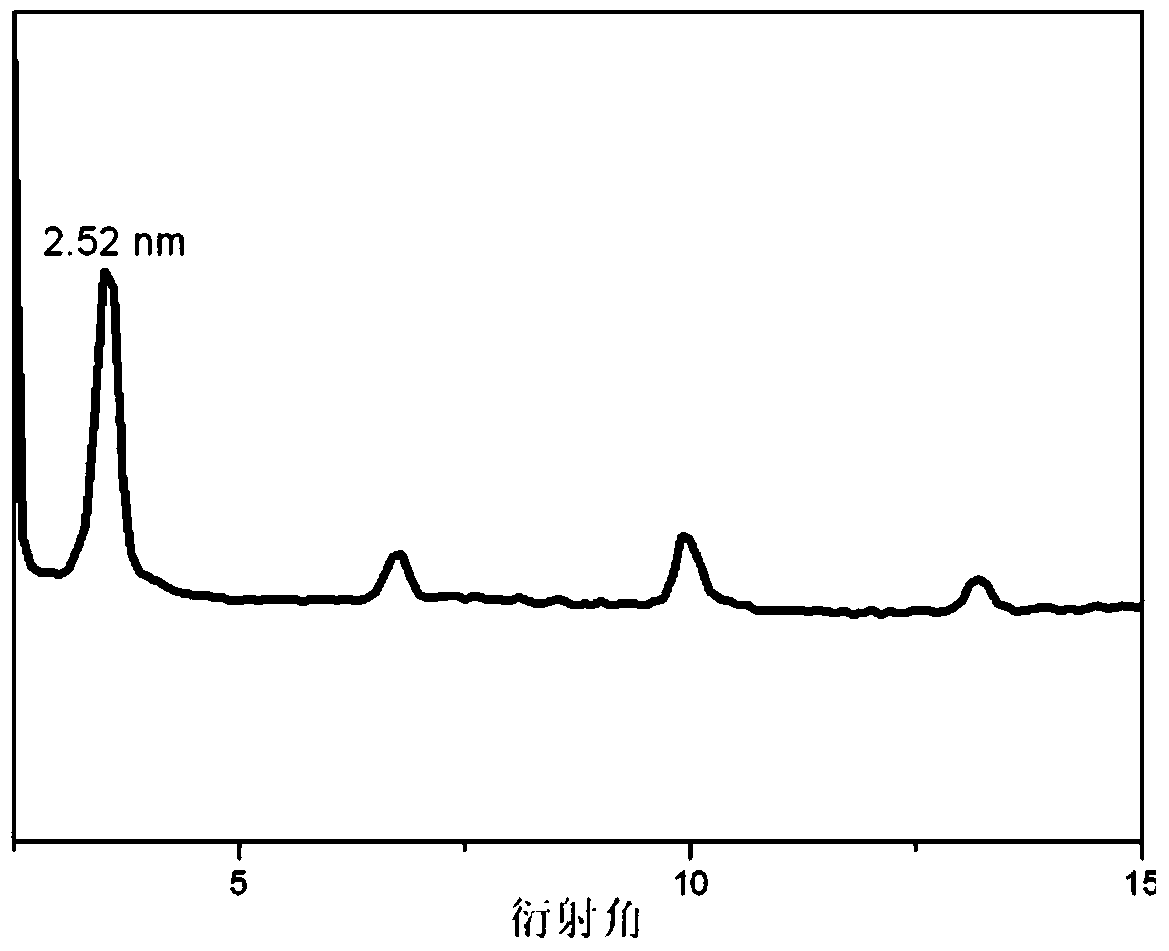

[0088] Utilize X-ray diffraction to analyze the fluorocarbon intercalation layered magnesium aluminum hydroxide obtained in embodiment 1, obtain its X-ray diffraction pattern, as figure 1 shown.

Embodiment 2

[0090] Add 500g of water, 1g of layered magnesium aluminum hydroxide and 3g of fluorocarbon surfactant sodium perfluorooctyl carboxylate to the reaction vessel in sequence, react at 40°C for 24h, filter, and vacuum dry at 80°C to obtain a fluorocarbon intercalation layer magnesium aluminum hydroxide.

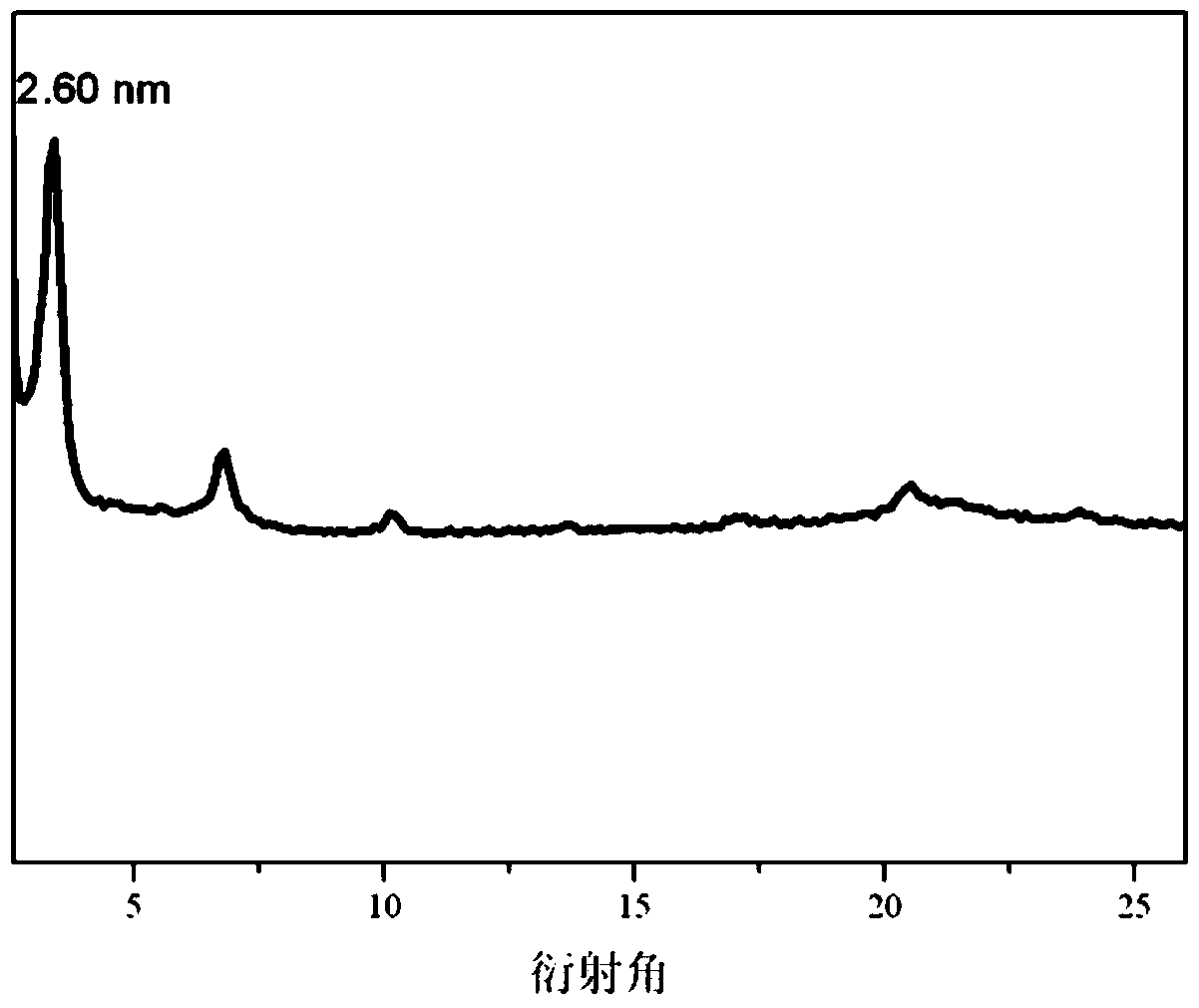

[0091] Utilize X-ray diffraction to analyze the fluorocarbon intercalation layered magnesium aluminum hydroxide obtained in embodiment 2, obtain its X-ray diffraction pattern, as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com