Intelligent control type tunnel automatic deicing trolley

A technology of intelligent control and deicing vehicles, which is applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of non-adjustable pole length, inconvenient use and carrying, and endangering train safety, so as to improve the deicing effect and reduce the High labor intensity and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples.

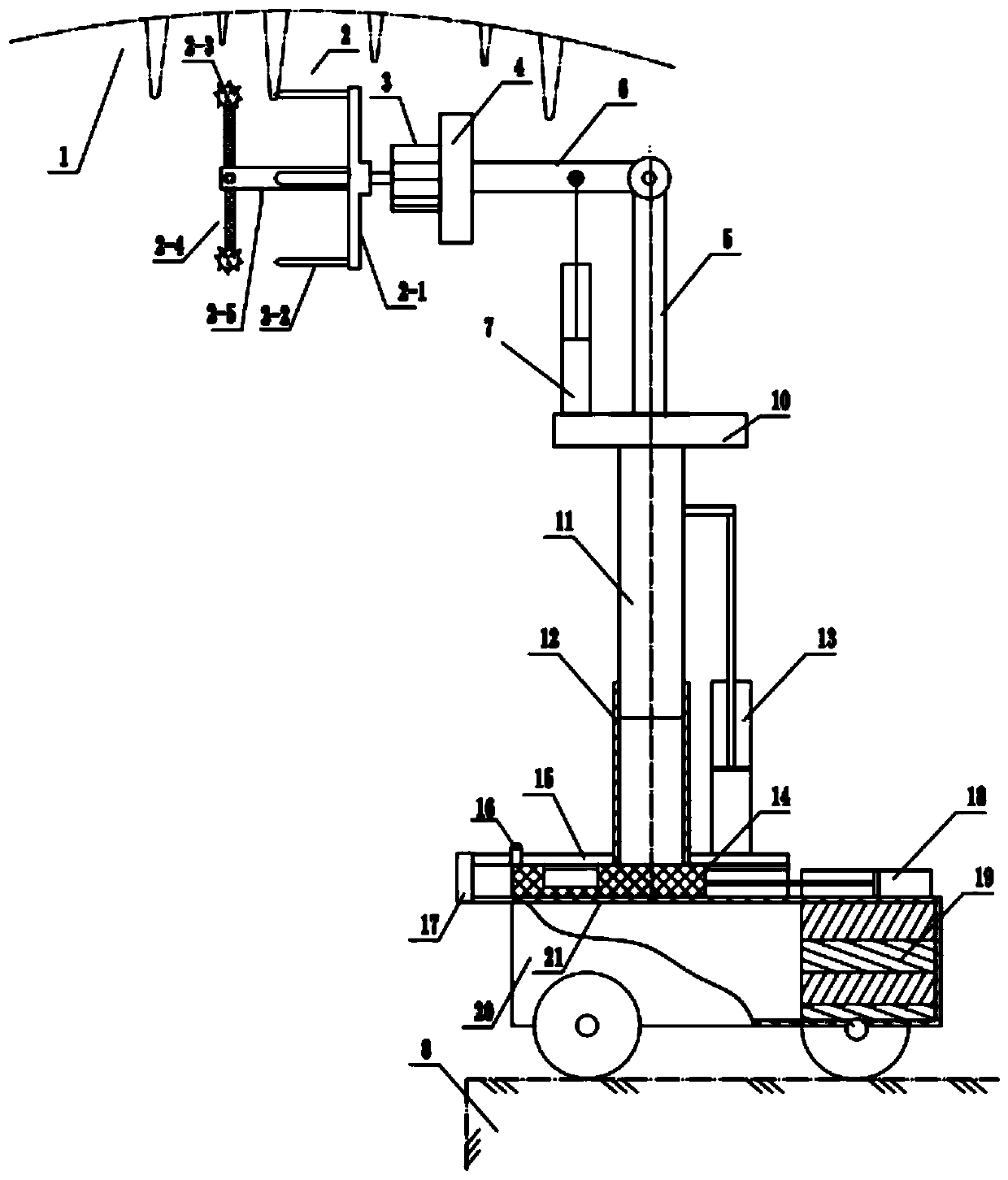

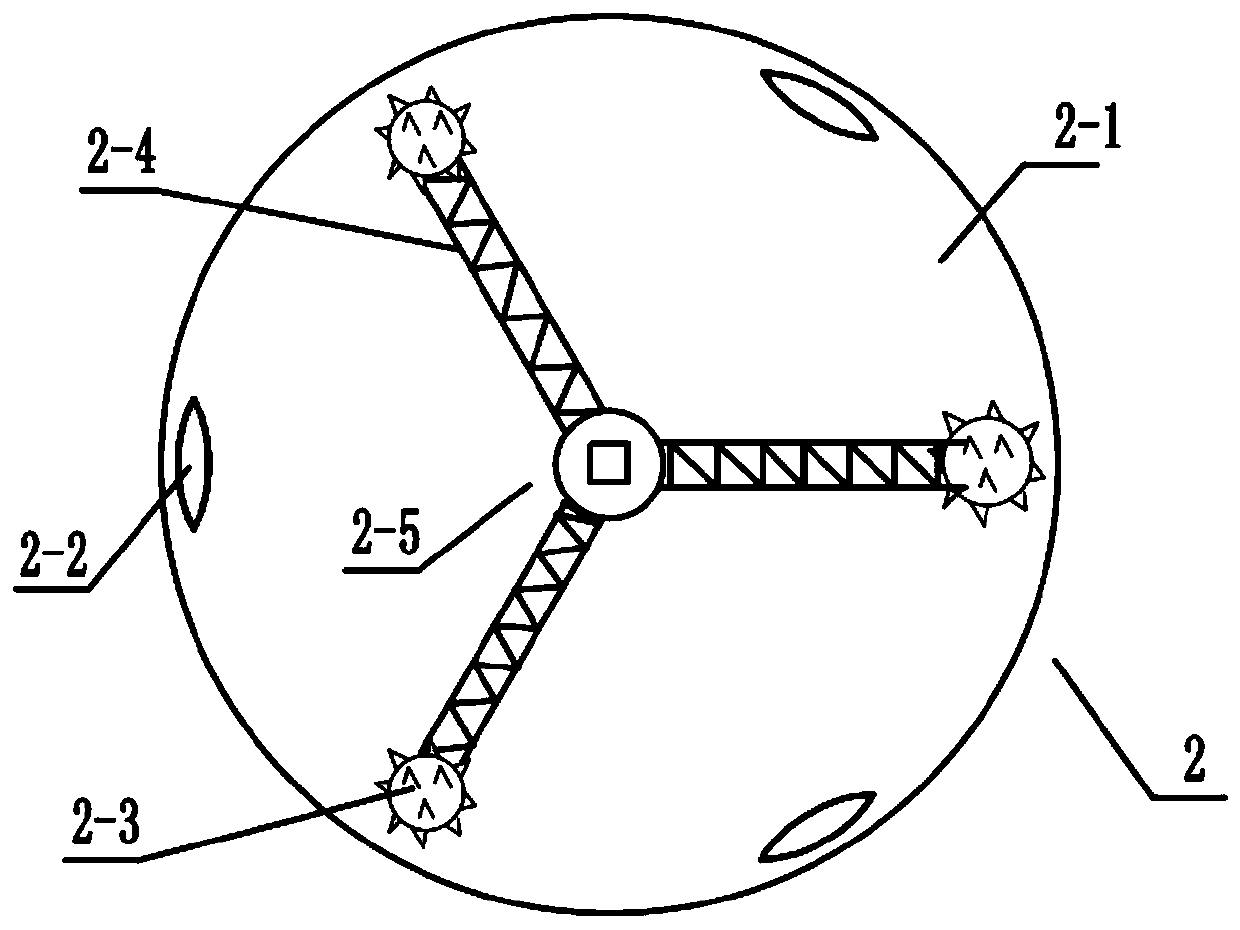

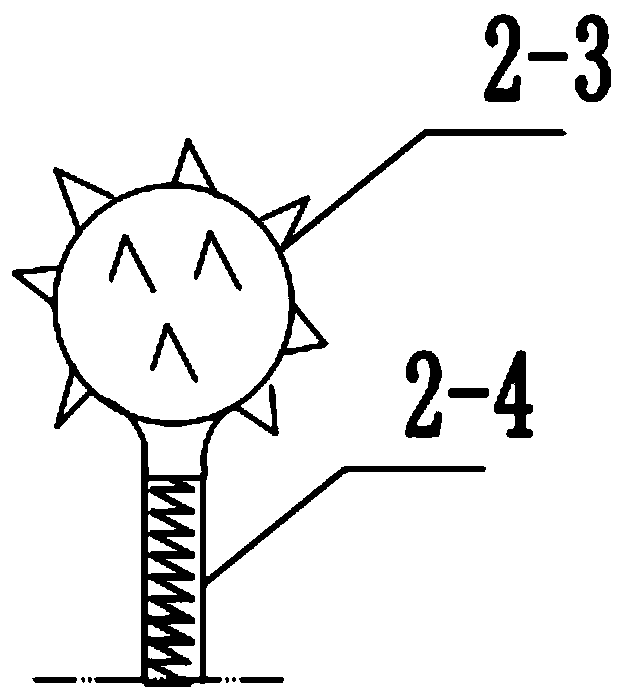

[0024] see figure 1 , The tunnel automatic deicing vehicle of the present invention includes a walking part, a lifting part and a deicing part, the lifting part is fixed on the platform of the walking part, the top seat 10 is fixed on the top of the lifting part, and the deicing part is connected above the top seat. part; the deicing part includes a deicing blade holder 2 and an angle adjustment mechanism, and the deicing blade holder consists of a wheel hub 2-1, a deicing blade 2-2, an ice hammer 2-3, an elastic rod 2-4 and an ice hammer central axis 2- 5 compositions. A plurality of the deicers are arranged, and the intervals are vertically evenly distributed on one side of the hub 2-1. The other side of the hub is provided with a shaft hole, which is connected to the output shaft of the drive motor 3 through the shaft hole; the ice hammer is also provided with The angle adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com