Large-treatment-capacity hydrate downhole separation parallel device using spiral separators

A spiral separator and hydrate technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of ineffective separation of mud and sand in hydrate raw slurry, insufficient processing capacity, etc., and is conducive to popularization Application, compact structure, and the effect of improving work ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

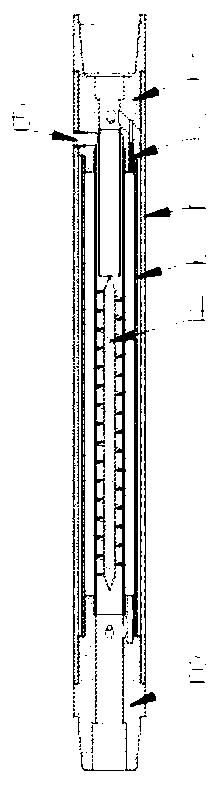

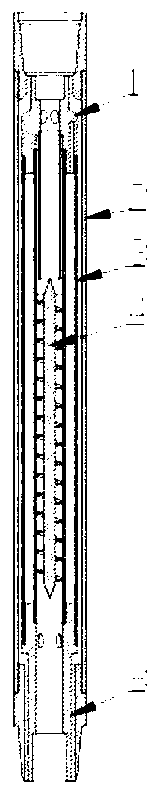

[0038] When the number of spiral separators 4 to be installed is one, the parallel assembly is not installed, and the plug 7 is installed on the top of the hydrate raw slurry channel of the bottom sub-section 8 and the bottom of the hydrate parallel channel of the top sub-section 1, and the isolation ring Empty and hydrate raw slurry channel, connect the outer pipe 2 with the bottom assembly, connect the spiral separator 4 and inner pipe 3 of the bottom assembly with the top nipple 1, and connect the outer pipe 2 with the top assembly.

[0039] When the hydrate raw slurry enters the screw separator 4 through the hydrate raw slurry channel of the bottom sub-section 8, it is separated into hydrate and mud sand, and the hydrate enters the hydrate parallel connection of the top sub-section 1 through the top hydrate outlet of the screw separator 4 In the upper row of the channel, the mud and sand enter the mud and sand channel of the top nipple 1 through the mud and sand outlet at t...

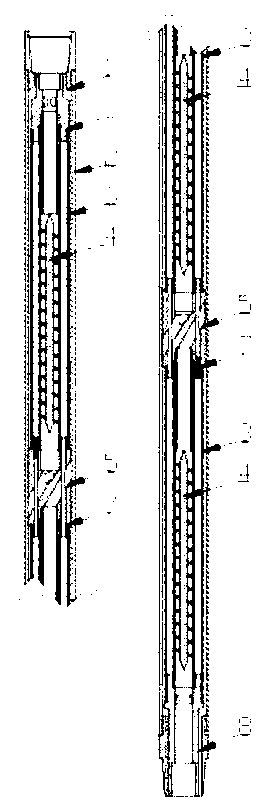

Embodiment 2

[0041] When the number of spiral separators 4 to be installed is two or more, the total number of spiral separators 4 required for installation is reduced by one parallel assembly, and the top of the spiral separator 4 and the top of the outer tube 2 of the first parallel assembly are connected to the top Connect the puppet 1, and fix the position of the inner pipe 3, connect the top of the spiral separator 4 and the top of the outer pipe 2 of each other parallel assembly with the previous parallel puppet 5, and fix the position of the inner pipe 3. The head 7 is installed at the bottom of the hydrate parallel channel of the parallel sub-section 5 connected to the bottom assembly and the top of the hydrate slurry channel of the parallel sub-section 5 connected with the top sub-section 1 to isolate the annulus of the inner pipe 3 from the Hydrate parallel channel, install the outer pipe 2 through the parallel sub-section 5 on the top sub-section 1, connect the spiral separator 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com