Nut and bolt locking method and locking gasket thereof

A technology of anti-loosening washers and bolts, which is applied in the direction of nuts, bolts, washers, etc., can solve the problems of hydrogen embrittlement fracture of spring washers, opening ring expansion, uneven pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

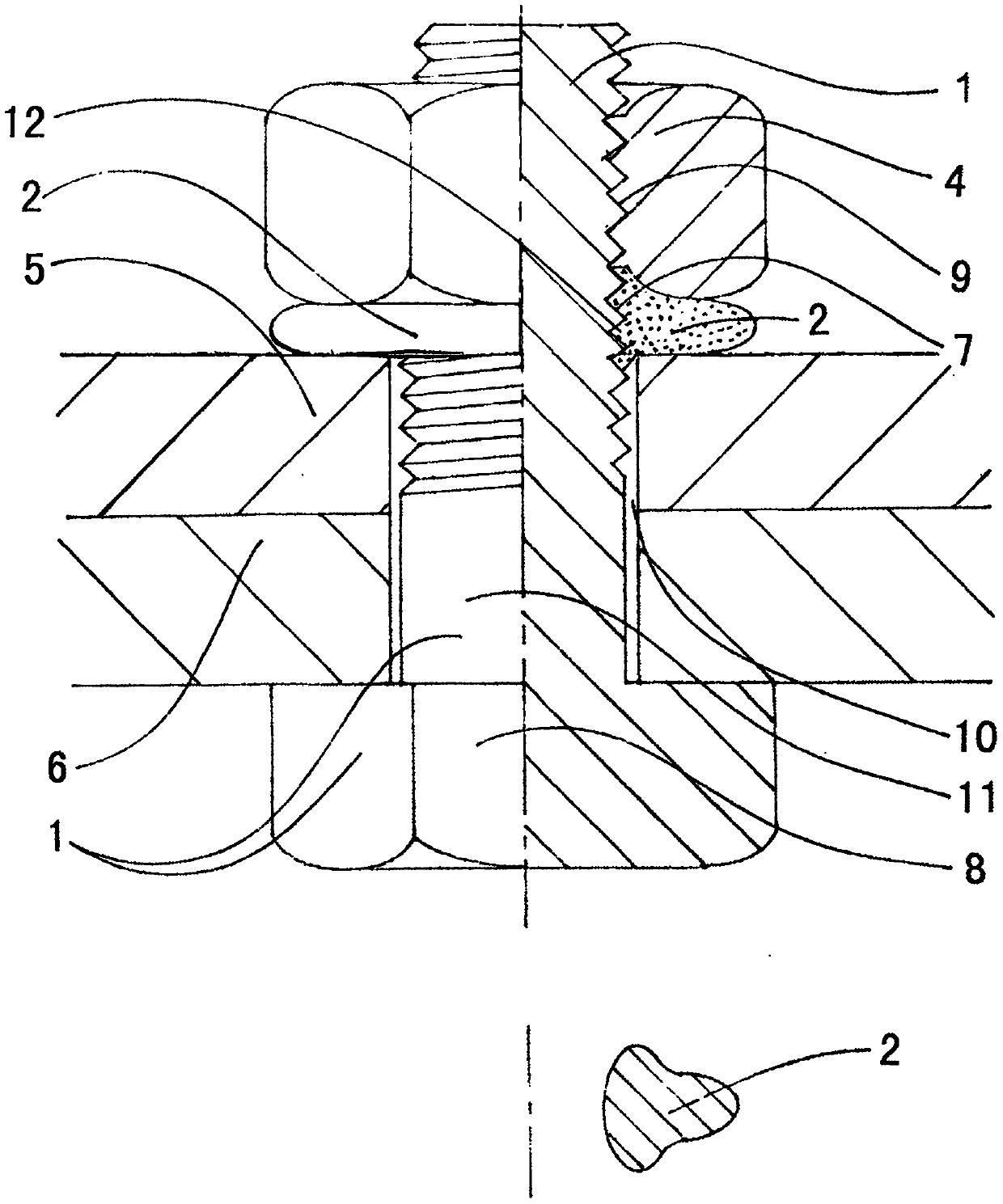

[0026] The locking method of the nut and the bolt of the present invention is to replace the commonly used spring washer with the rubber washer 2, and the flat washer is omitted.

[0027] figure 1 Among them, the present invention includes a bolt 1, a nut 4, a lock washer 2, and the bolt 1 passes through the screw hole 10 of the fastened part A 5 and the fastened part B 6, and will expose the fastened part 5 and be fastened Put the rubber washer 2 on the bolt outer thread 7 of the screw rod 11 of the bolt 1 behind the part 6, screw on the nut inner thread 9 of the nut 4, and tighten it, because the rubber washer 2 of the anti-loosening washer 2 is extruded. The expansion force of the spring back is extruded, so that the bolt 1, the rubber washer 2, the nut 4, and the fastener A 5 are elastically fixed into one body through the extruded and deformed rubber washer 2. At this time, the gap between the four , the inner edge of the extruded rubber washer 2 fills the gap 12 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com