Vacuum phase change boiler

A boiler and phase change technology, which is used in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of large fluctuation of water temperature and increase the loss of heating devices, so as to increase roughness and improve adhesion. , the effect of accelerating the rate of pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

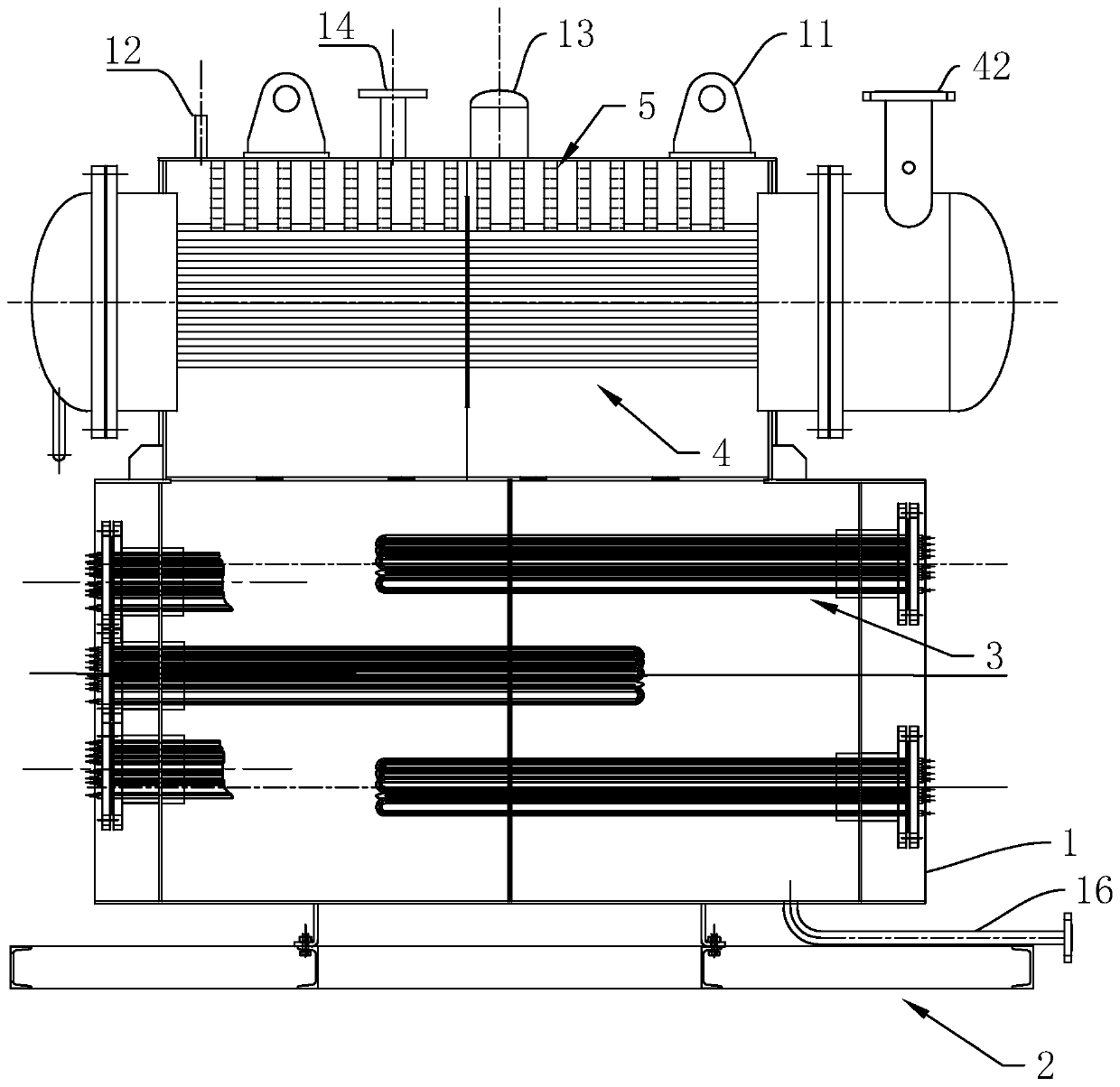

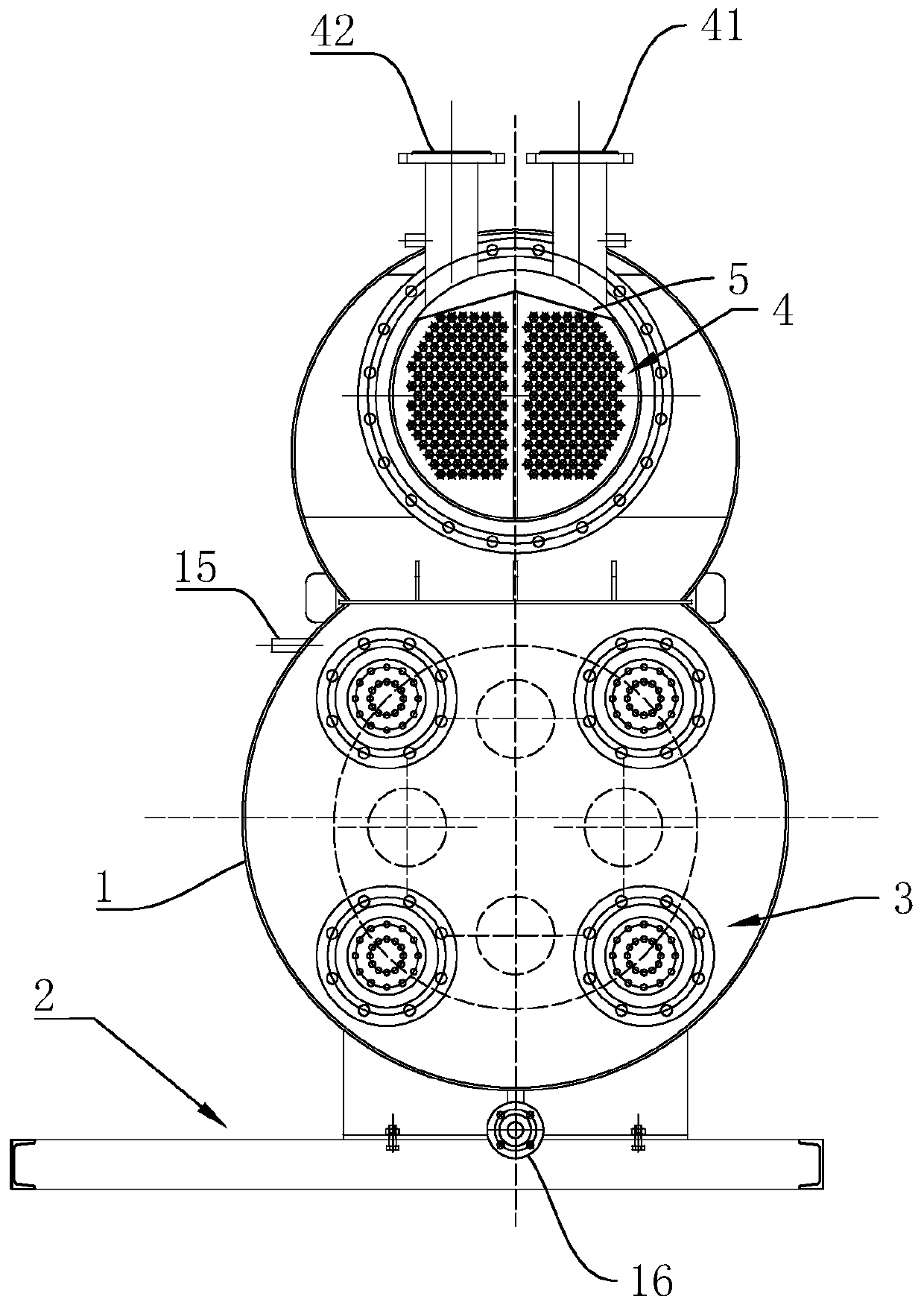

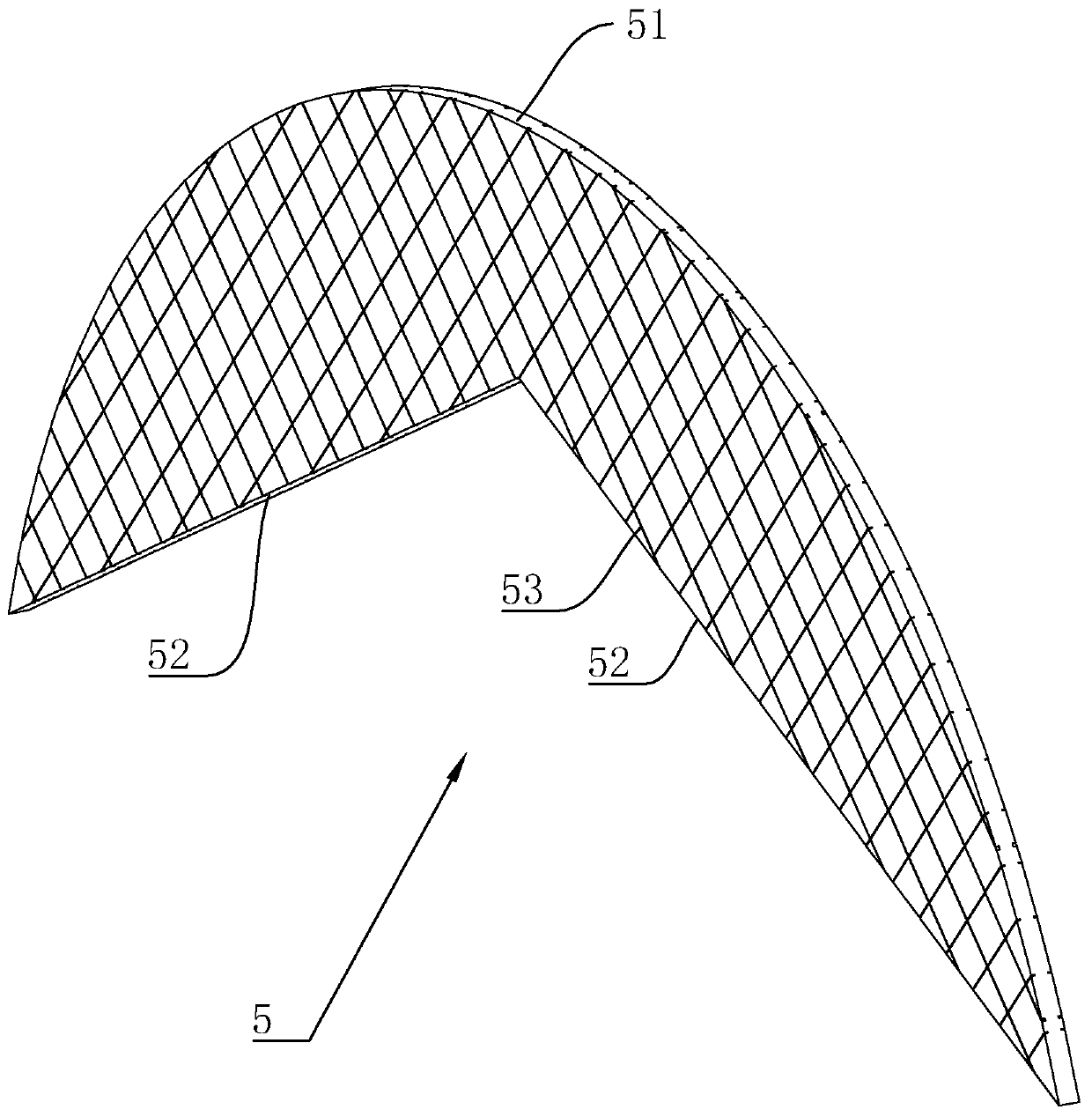

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] see figure 1 and figure 2 , the invention discloses a vacuum phase change boiler, which includes a furnace body 1 . The vertical section of the furnace body 1 is gourd-shaped, and the vertical plane cutting the furnace body 1 is perpendicular to the length direction of the furnace body 1 . A base 2 is welded on the bottom of the furnace body 1 . The furnace body 1 is arranged in a sealed manner, and the interior of the furnace body 1 is set in a negative pressure and vacuum environment. An electric heating rod 3 and a heat exchanger 4 are installed inside the furnace body 1 , and heat medium water is also injected in the furnace body 1 . The electric heating rod 3 is located below the heat exchanger 4, and the heat medium water submerges the electric heating rod 3 but does not involve the heat exchanger 4.

[0034] The heat released by the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com