Structural optimization method for parallel load distribution type six-component force sensor

A technology of six-dimensional force sensor and optimization method, which is applied in the field of measurement, can solve problems such as ambiguous relationships, achieve simple calculations, achieve miniaturization and standardization, and have low requirements for computing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing, technical solution of the present invention is described in further detail:

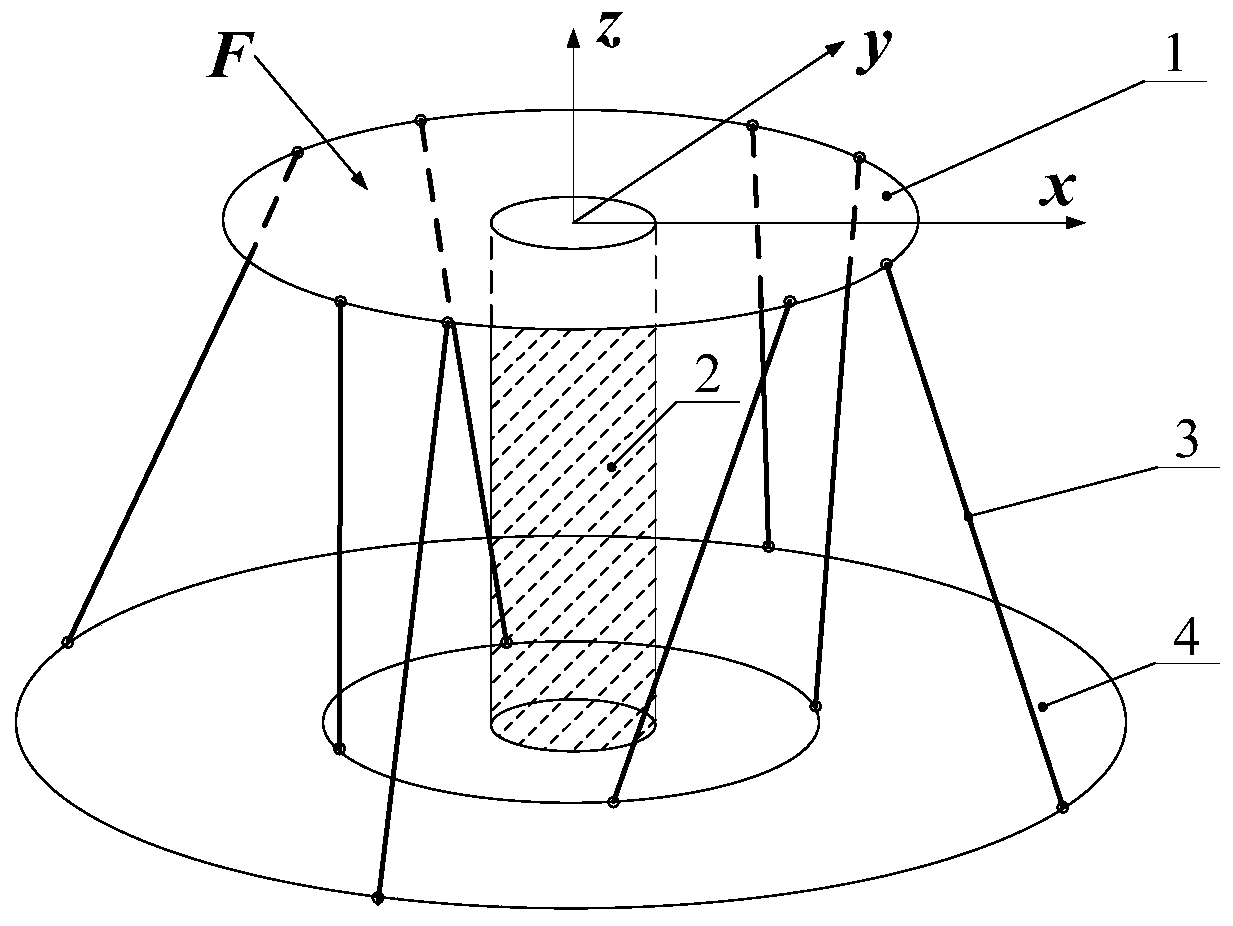

[0052] Such as figure 1 As shown in this figure, the device used in the structure optimization method of the parallel load-sharing six-dimensional force sensor of the present invention includes an upper platform 1, a central load beam 2, a branch chain 3 arranged in parallel, and a lower platform 4. The external load of the sensor acts on the upper platform 1 . The branch chain 3 arranged in parallel, the upper platform 1 and the lower platform 4 form a Stewart parallel structure.

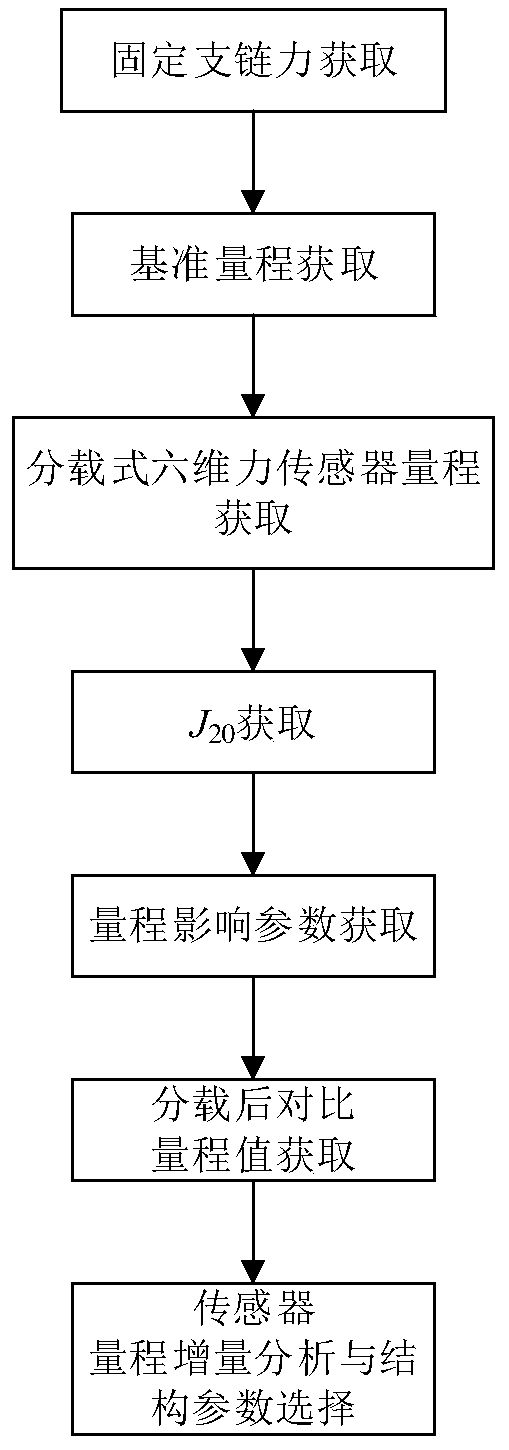

[0053] The steps of the structural optimization method for the parallel load-sharing type six-dimensional force sensor using the above-mentioned device are as follows:

[0054] Step 1. Acquisition of fixed branch force

[0055] According to the strength limit of each branch chain of the sensor, to ensure that each branch chain is in a safe working state, the maximu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com