Intelligent apple processing equipment for mass production

An intelligent processing and apple technology, applied in the field of mass production apple intelligent processing equipment, can solve the problems of low hygiene standards, uneven peeling thickness, incomplete cleaning, etc., and achieve the effect of improving hygiene standards and reducing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

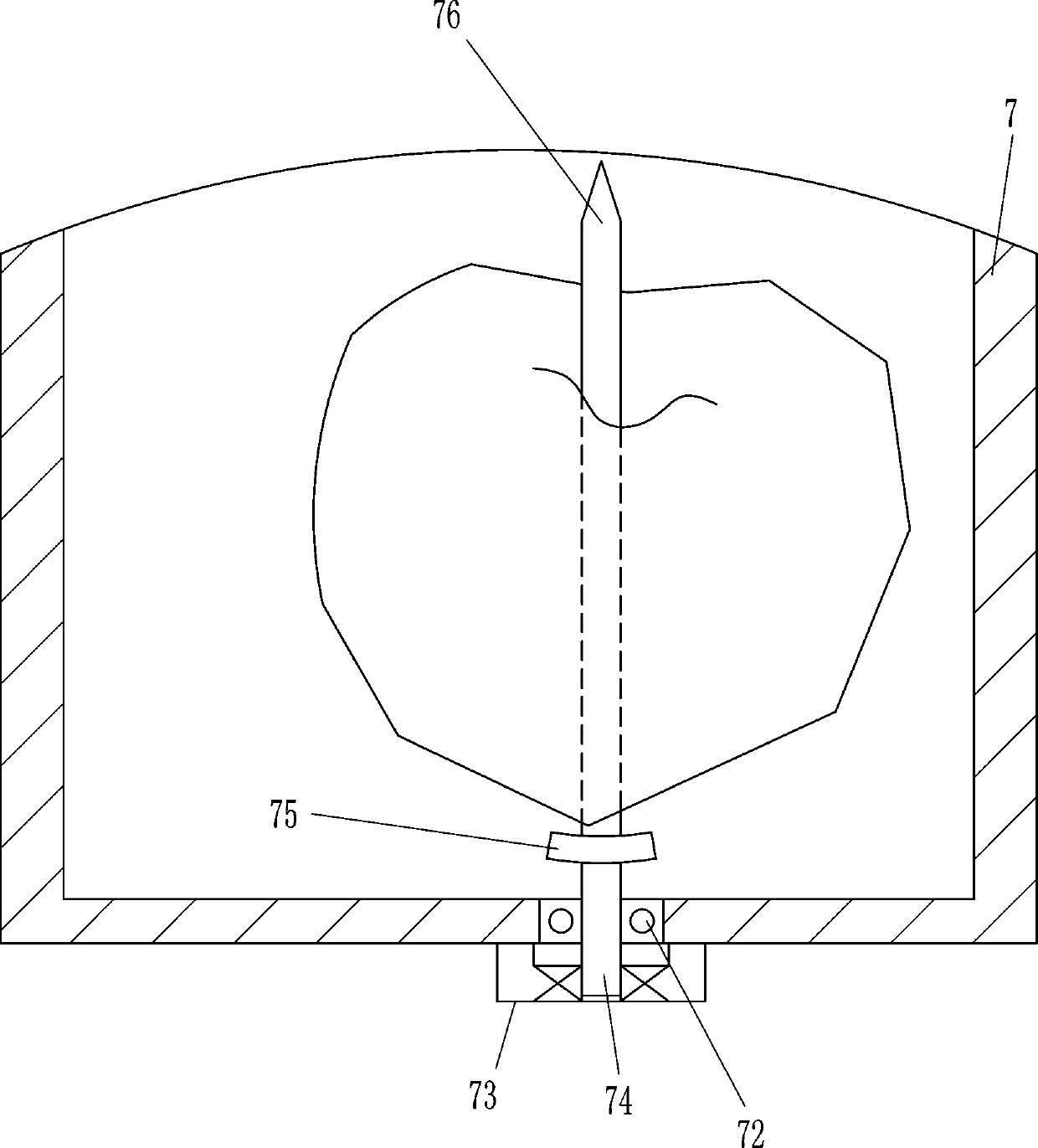

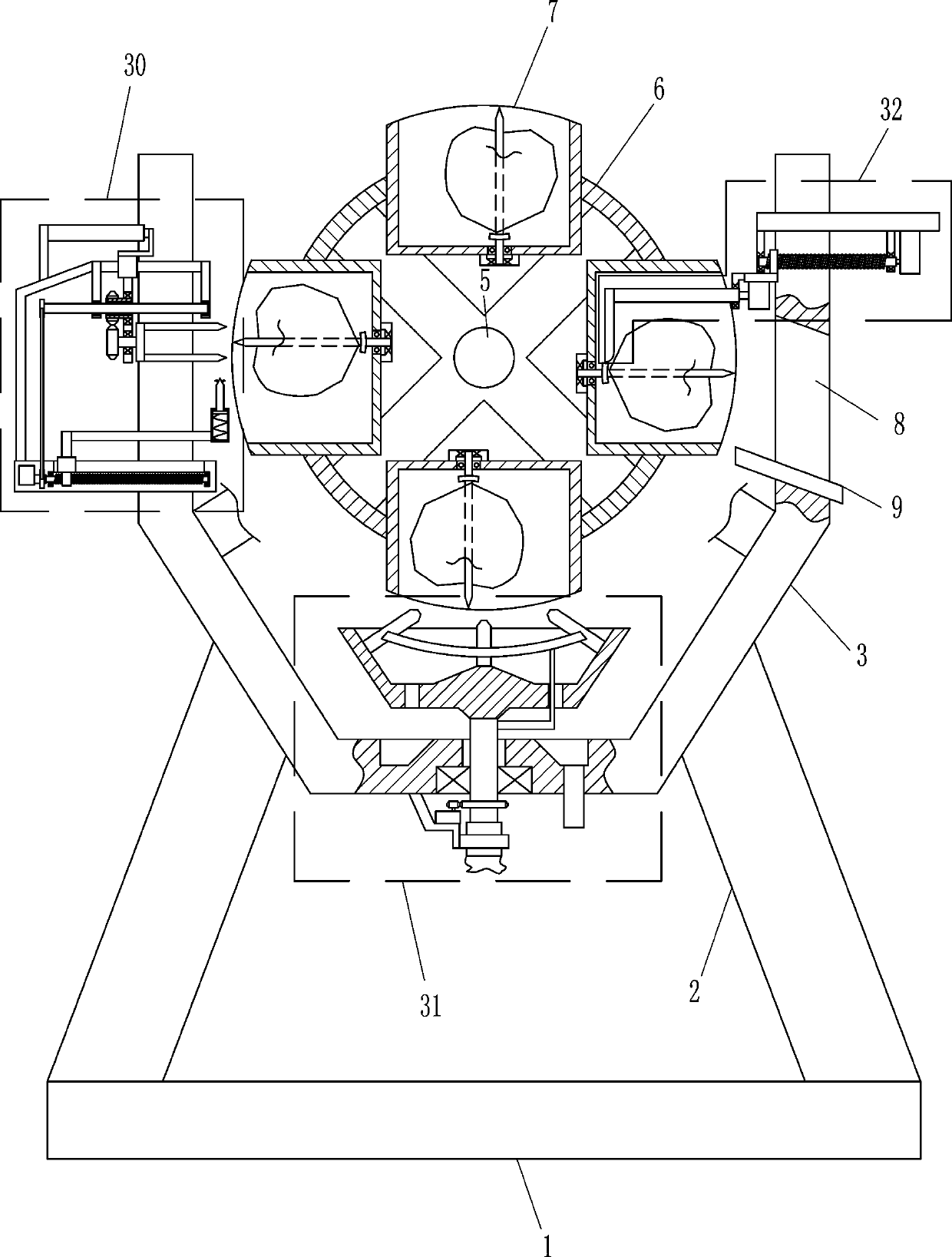

[0027] A mass-produced apple intelligent processing equipment, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 and Figure 10 As shown, it includes a base plate 1, a control box 101, a main power switch 102, a bracket 2, a mounting frame 3, a first connecting frame 4, a first rotating rod 5, a first bearing seat 51, a first gear 52, and a first motor Seat 53, first drive motor 54, second gear 55, fixed plate 56, contact switch 57, N-shaped bar 58, first mounting plate 6, processing box 7, first seal ring 72, second bearing seat 73, the first Two rotating rods 74, stopper 75, puncture rod 76, sliding plate 9, peeling device 30, cleaning device 31 and fruit return device 32, are provided with control box 101 in the middle of bottom plate 1 top, include power supply module and in control box 101 Control module, the switching power supply is connected with the power module through the circuit, the power module is connected with the control module through the c...

Embodiment 2

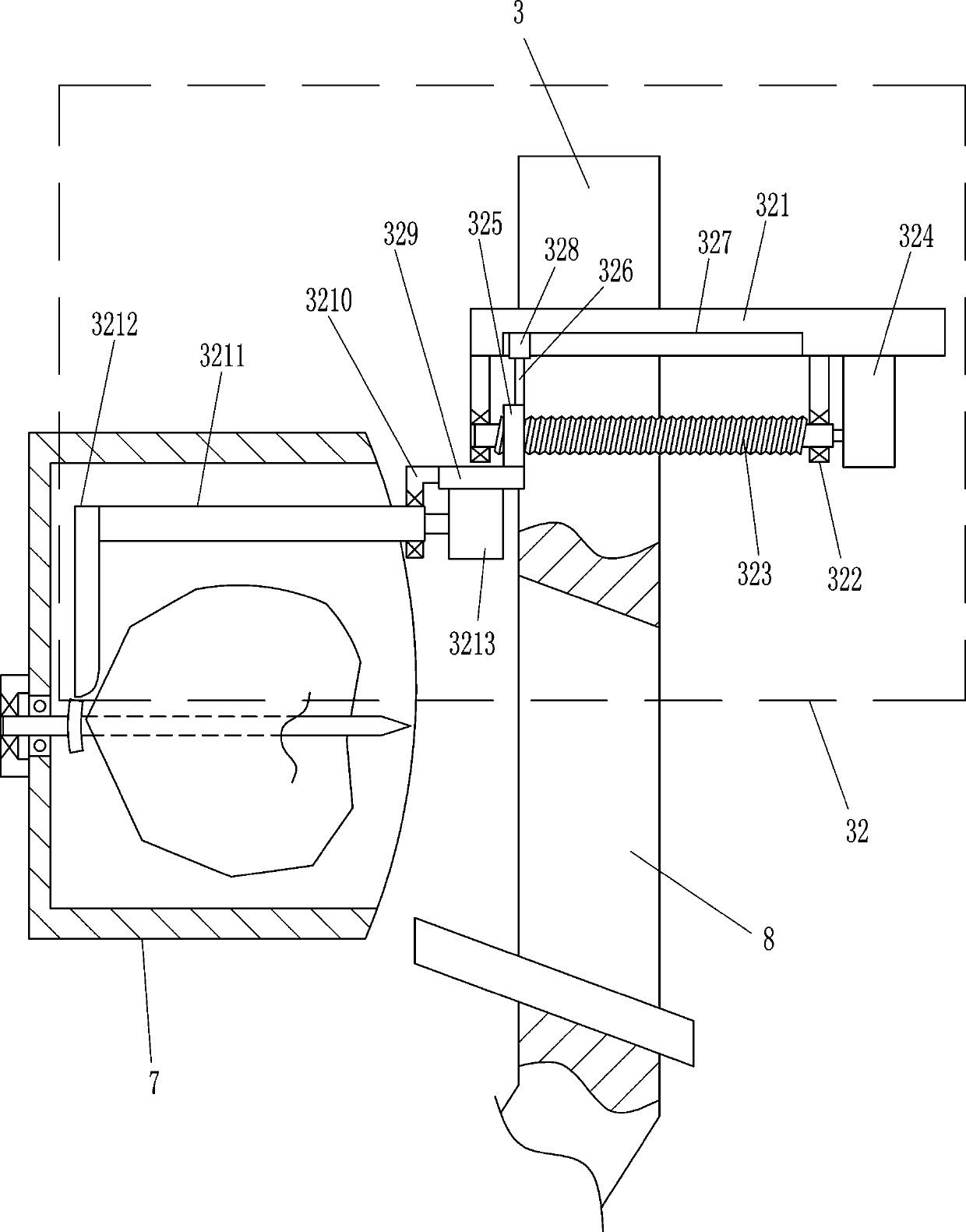

[0030] On the basis of Example 1, such as Figure 5 , Figure 9 and Figure 10As shown, the peeling device 30 includes a mounting plate 301, a first slide rail 302, a first slider 303, a first L-shaped bar 304, a mounting sleeve 305, a spring 306, a first moving block 307, a scraper 308, a third Bearing seat 309, first screw rod 3010, gear motor 3011, first nut 3012, second connecting frame 3013, fixed rod 3014, guide rail 3015, guide sleeve 3016, second L-shaped rod 3017, mounting base 3018, electric push rod 3019, mounting rod 3020, fourth bearing seat 3021, third rotating rod 3022, second mounting disc 3023, inserting rod 3024, third gear 3025, fifth bearing seat 3026, keyway rotating ring 3027, fourth gear 3028, The sixth bearing seat 3029, the keyed rotating rod 3030, the pulley 3031 and the flat belt 3032, the mounting plate 301 is provided on the front side of the left part of the mounting frame 3, and the first slide rail 302 is provided on the top of the mounting pl...

Embodiment 3

[0033] On the basis of Example 2, such as Image 6 , Figure 9 and Figure 10 As shown, the cleaning device 31 includes a seventh bearing seat 312, a hard water pipe 313, a water collecting bucket 314, a spray pipe 316, an arc-shaped water pipe 317, a water supply pipe 318, an external drain pipe 319, a fifth gear 3110, and a third connecting frame 3111, the second driving motor 3112, the sixth gear 3113, the rotary joint 3114 and the external water supply pipe 3115, the lower part of the installation frame 3 has a sink 311, the bottom of the installation frame 3 is embedded with the seventh bearing seat 312, the seventh bearing seat 312 is equipped with a hard water pipe 313, the top of the hard water pipe 313 is provided with a water collecting bucket 314, the water collecting bucket 314 is located below the processing box 7 below, and the inner bottom of the water collecting bucket 314 is evenly provided with a plurality of water holes 315, and the water hole 315 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com