Modified polysiloxane and application thereof

A polysiloxane and modification technology, applied in the field of modified polysiloxane, can solve the problems of complicated preparation methods, achieve unique application prospects, and improve the effect of temperature-sensitive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

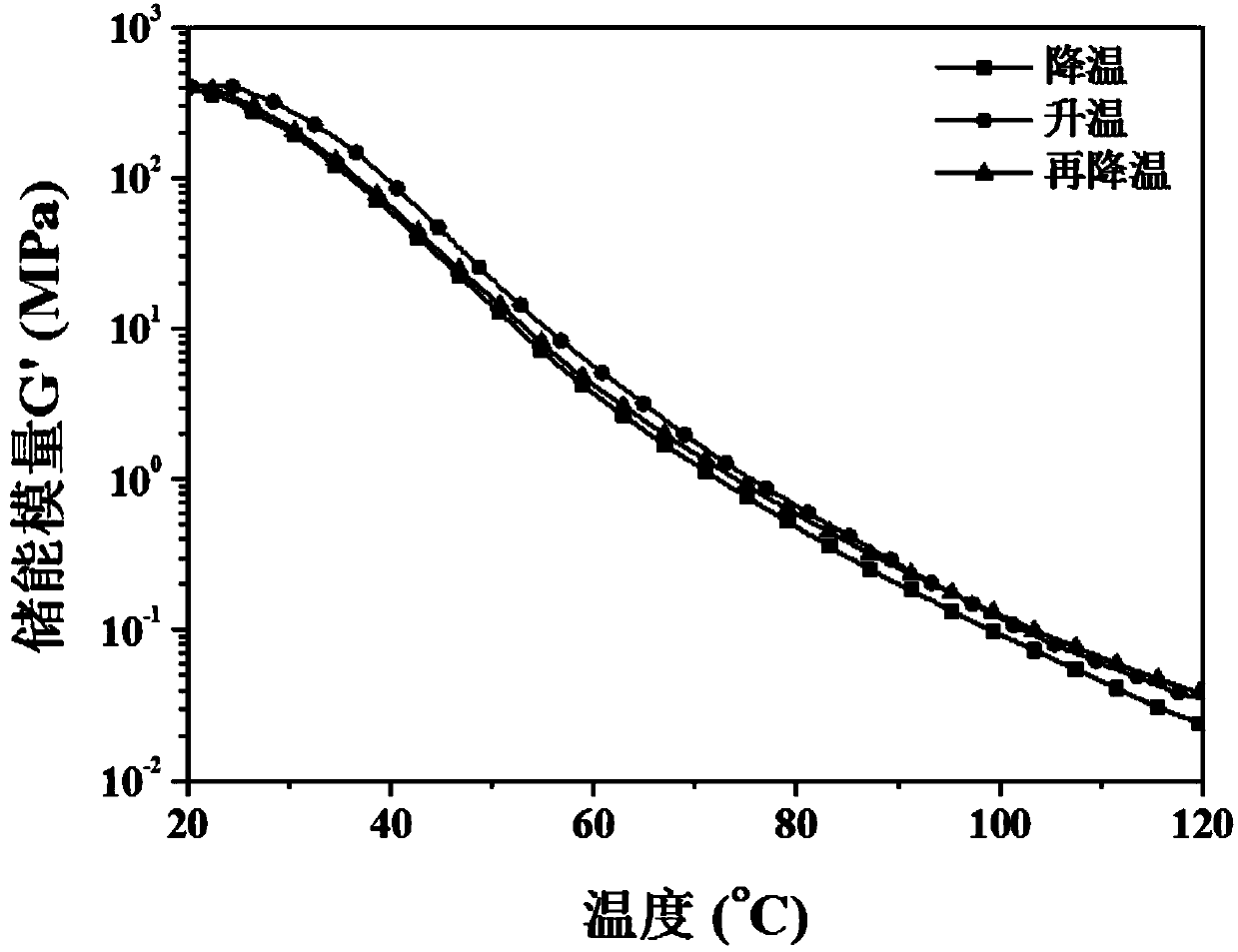

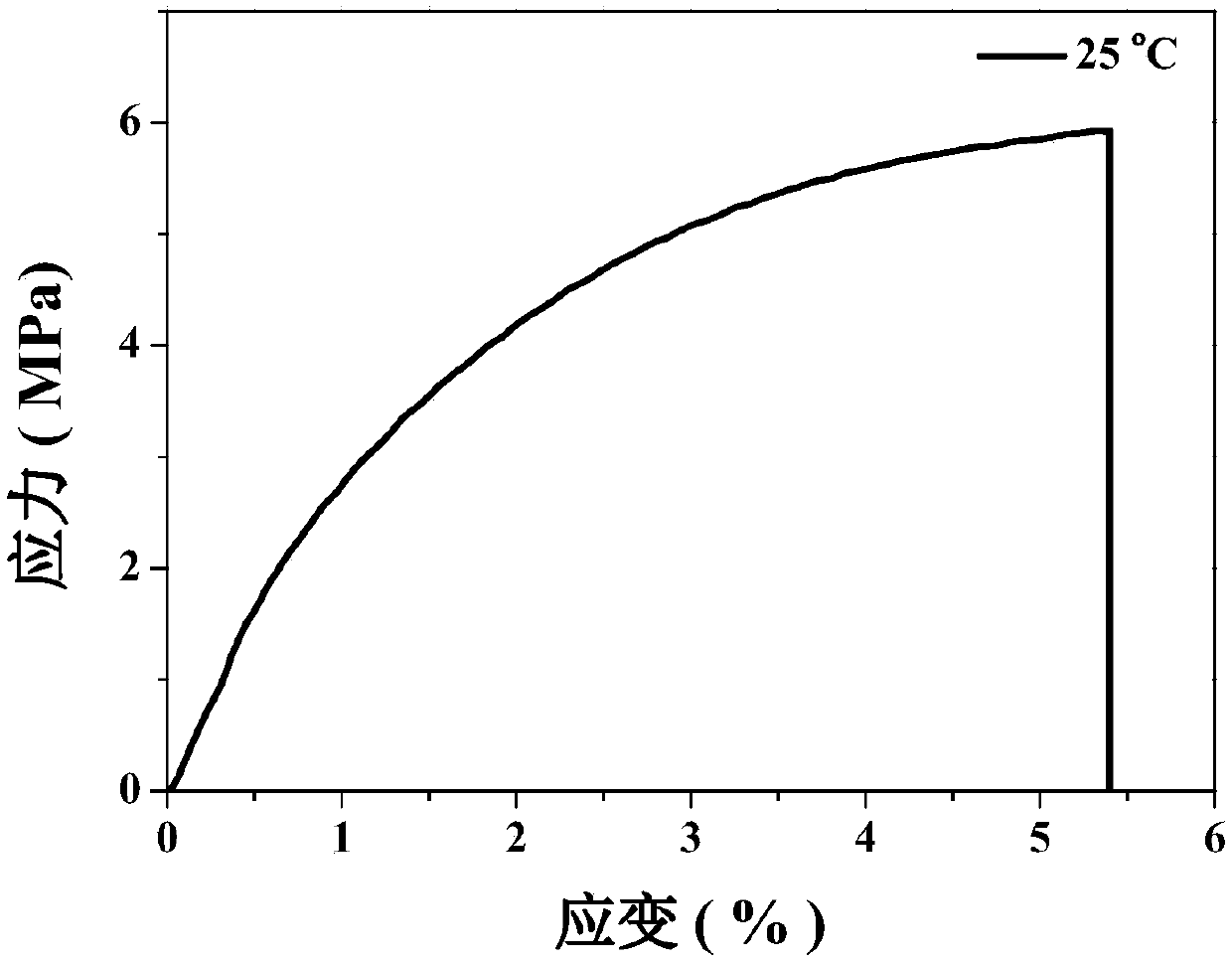

[0118] Embodiment 1 temperature-sensitive polymer material based on hydrogen bond

[0119] Step 1: In a dry four-neck flask equipped with a thermometer, a condenser, a dropping funnel, and an Ar inlet, add 150 g of anhydrous toluene, start stirring, and add 72 g of allyl glycidyl ether (0.63 mol) to the toluene , and then 37.5g hydrogen content is 1.6wt% (Mn~3000, wherein, R 1 -R6 is a methyl group, m is 0, n is a value in the range of 40 to 55, and 0.6 mol per mole of Si-H) polyalkylhydrosiloxane is added to the mixed reaction system of toluene and allyl glycidyl ether middle. Then 20mg of Karstedt platinum catalyst (20wt%Pt) was added dropwise into the mixed reaction system. After the dropwise addition, the temperature was controlled at 50° C., and the reaction was continued for 12 hours. After the reaction was finished, 105.5 g of polysiloxane functionalized with allyl glycidyl ether was obtained by distillation under reduced pressure, with a yield of 97.2%. through 1 ...

Embodiment 2

[0132] Embodiment 2 temperature-sensitive polymer material based on hydrogen bond

[0133] Step 1: In a dry four-necked flask equipped with a thermometer, a condenser, a dropping funnel, and an Ar inlet, add 150 g of anhydrous toluene, start stirring, and add 72 g of methyl methacrylate (0.72 mol) to the toluene, Then 75g hydrogen content is 0.8wt% (Mn~4000, wherein, R 1 -R6 is a methyl group, m / n is 1 / 1, m is a value in the range of 30 to 40, n is a value in the range of 30 to 40, 0.6 mol per mole of Si-H) polyalkylhydrosiloxane is added To the mixed reaction system of toluene and methyl methacrylate. Then 20mg of Karstedt platinum catalyst (20wt%Pt) was added dropwise into the mixed reaction system. After the dropwise addition, the temperature was controlled at 50° C., and the reaction was continued for 12 hours. After the reaction was finished, 131.5 g of polysiloxane functionalized with methyl methacrylate was obtained by distillation under reduced pressure, with a yiel...

Embodiment 3

[0142] Embodiment 3 temperature-sensitive polymer material based on hydrogen bond

[0143] Step 1: In a dry four-neck flask equipped with a thermometer, a condenser, a dropping funnel, and an Ar inlet, the 131.5 g of methyl methacrylate functionalized polysiloxane obtained in step 1 in Example 2 were respectively Alkanes were dissolved in 150mL tetrahydrofuran, and 36g lithium aluminum hydride was added to the system. Turn on the magnetic stirring, and control the reaction temperature at 25° C., and continue the reaction for 12 hours. After the reaction, the organic phase was collected by filtration, and then the solvent was removed by distillation under reduced pressure to obtain 112.3 g of the final product hydroxyl-functionalized polysiloxane with a yield of 93.8%. The reaction formula is as follows:

[0144]

[0145] The mechanism of hydrogen bonding in the above hydroxyl-functionalized polysiloxane structure under temperature change is as follows:

[0146]

[014...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com