Method for anhydrous tanning of leather

A tanning and leather technology, which is applied in the field of anhydrous tanning leather based on ionic liquid/organic solvent system, can solve the problems of high solution viscosity, large internal mass transfer resistance of leather core, and restriction of tanning effect, etc., so as to reduce mass transfer resistance , Enhance the effect of tanning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

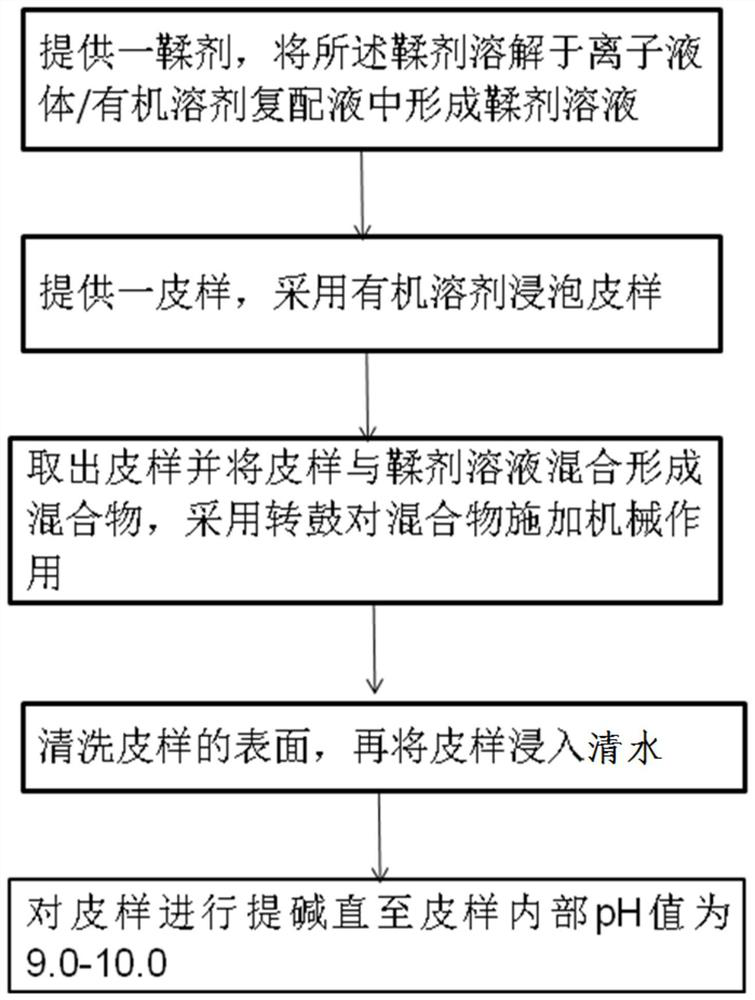

Method used

Image

Examples

preparation example Construction

[0018] In step S1, the concentration of the tanning agent in the ionic liquid / organic solvent compound solution is 3%-6%. The tanning agent is a modified natural macromolecule tanning agent. Specifically, the preparation method of the tanning agent comprises the following steps:

[0019] In step 1, a natural macromolecular raw material is provided, the raw material is stirred, and sodium periodate is added to the raw material to perform a light-proof reaction.

[0020] The natural macromolecular raw materials can be microcrystalline cellulose, sodium alginate, guar gum, chitosan and carrageenan. After adding sodium periodate, the mass ratio of sodium periodate to natural macromolecular raw material is 1 / 3-2 / 1. The reaction time in the dark is 4-12 hours. During the reaction in the dark, the pH value of the solution was kept at 3-4.5, and the temperature was kept at 30-50°C.

[0021] Step 2, adding ethylene glycol to terminate the reaction, stirring the reaction at room tem...

Embodiment 1

[0031] (1) Weigh chitosan and disperse in water. Add sodium periodate (m (sodium periodate) / m (macromolecular raw material)=1 / 1) under stirring, and react in the dark for 4 hours. During the reaction, the pH value of the solution was maintained at 4.5 and the temperature was 50°C. After the end, ethylene glycol was added to terminate the reaction. Centrifuged, washed with absolute ethanol and deionized water for 5 times successively, freeze-dried, and ground to obtain powdery oxidized chitosan, which was used as a leather tanning agent.

[0032] (2) get an appropriate amount of tanning agent, dissolve in 1-ethyl-3-methylimidazolium bromide / acetone compound solvent (1-ethyl-3-methylimidazolium bromide volume percentage is 30%), make tanning The concentration of the agent is 3%. Take an appropriate amount of skin samples, soak them in acetone for dehydration, and change the liquid 3 times. The tanning agent solution was mixed with the leather sample to make the mass ratio of...

Embodiment 2

[0034] (1) Weigh microcrystalline cellulose and disperse in water. Add sodium periodate (m (sodium periodate) / m (macromolecular raw material)=1 / 3) under stirring, and react in the dark for 12h. During the reaction, the pH value of the solution was kept at 3.5 and the temperature was 40°C. After the end, ethylene glycol was added to terminate the reaction. Centrifuged, washed with absolute ethanol and deionized water for 4 times successively, freeze-dried, and ground to obtain powdery oxidized cellulose, which was used as a leather tanning agent.

[0035](2) Take an appropriate amount of tanning agent, dissolve it in 1-ethyl-3-methylimidazole acetate / dimethyl sulfoxide compound solvent (1-ethyl-3-methylimidazole acetate volume percentage is 70%) ), the tanning agent concentration was 4.5%. Take an appropriate amount of skin samples, soak them in dimethyl sulfoxide for dehydration, and change the liquid once. The tanning agent solution was mixed with the leather sample to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com