Device and method for cutting boulder in front of tunnel by using high-pressure water

A high-pressure water and tunnel technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems that are difficult to deal with quickly, affect the efficiency and safety of tunnel construction, and achieve the effect of improving efficiency, safety, and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

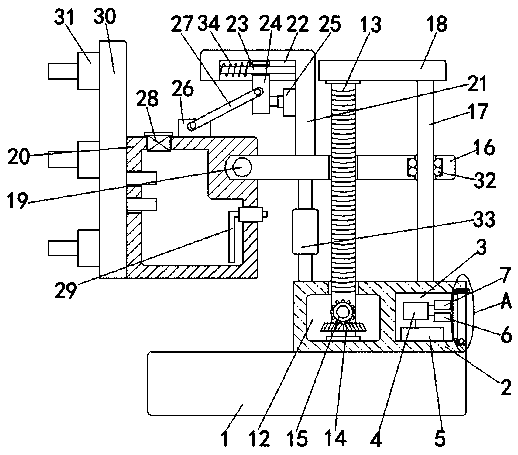

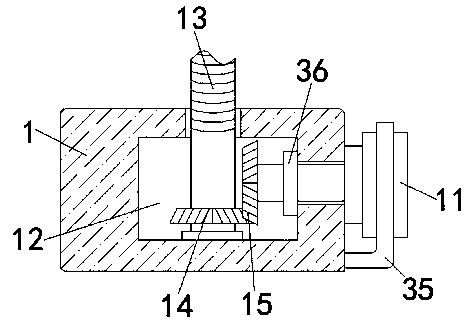

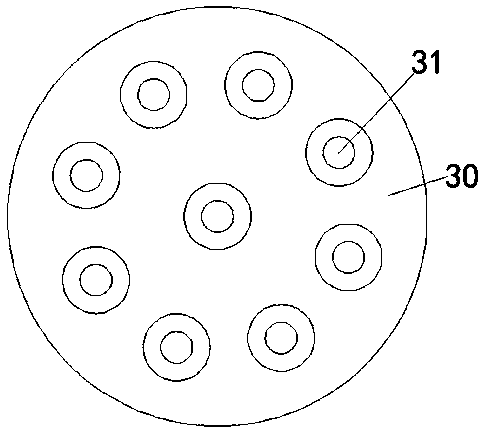

[0034] Reference Figure 1-4 , A device that uses high-pressure water to cut the boulder in front of the tunnel. It includes a base 1 and a mounting block 2. The mounting block 2 and the top of the base 1 are fixedly connected. One end of the mounting block 2 is provided with a device cavity 3 for setting various electronics The device cavity 3 is provided with a controller 4, a power supply 5, a signal receiver 6 and a signal transmitter 7 in sequence. The output terminal of the controller 4 is connected with the output terminal of the signal transmitter 7 for sending signals to the signal transmitter The output ends of the device 7, the power supply 5 and the signal receiver 6 are all connected to the input end of the controller 4 for receiving signals and supplying power to the controller 4. The inner wall of the device cavity 3 is provided with a port through which The first rotating shaft 8 is rotatably connected with a baffle 9 to protect the electrical components in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com