Rapid filling auxiliary device of hand-held oil gun

A technology of auxiliary equipment and oiling gun, which is applied in mechanical equipment, manual supply of lubricant, and input of lubricating oil, etc. It can solve the problems of grease layering in oil storage tanks, scratches by operators, and affecting oiling efficiency, etc., and achieve oiling efficiency Improvement, construction efficiency improvement, and the effect of improving oil injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

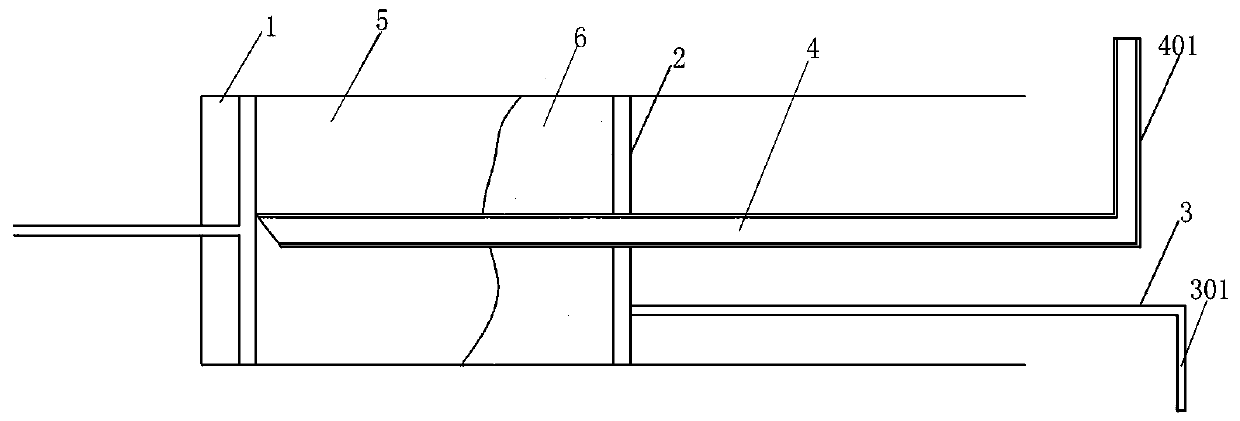

[0020] Example: see figure 1 , in the figure, 1-hand-held grease gun, 2-filler plate, 3-auxiliary push rod, 4-exhaust pipe, 5-inner cavity, 6-grease, 301-arc handle, 401-arc structure.

[0021] Hand-held grease gun rapid filling auxiliary equipment, including filling plate 2, auxiliary push rod 3 and exhaust pipe 4, filling plate 2 is a circular plate structure, and its diameter matches the diameter of the inner cavity 5 of the hand-held grease gun 1 to achieve filling The plate 2 can be placed in the inner cavity 5 and can move therein. The movement of the filling plate 2 is realized by the auxiliary push rod 3 connected thereto. The exhaust pipe 4 penetrates the filling plate 2 through the through hole on the filling plate 2 .

[0022] Further, the filler plate 2 is integrated with the auxiliary push rod 3 , and an arc-shaped handle 301 with an integral structure is provided away from the end of the filler plate 2 .

[0023] Further, the air intake end of the exhaust pipe 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com