Fan coil anti-freezing control method and system and air conditioner

A control method and technology for fan coil units, which are applied to heating and ventilation control systems, heating and ventilation safety systems, and control inputs involving air characteristics, etc. The problem of high pipe pressure, etc., achieves the effect of control method and effective, prolonging service life, and precise antifreeze operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

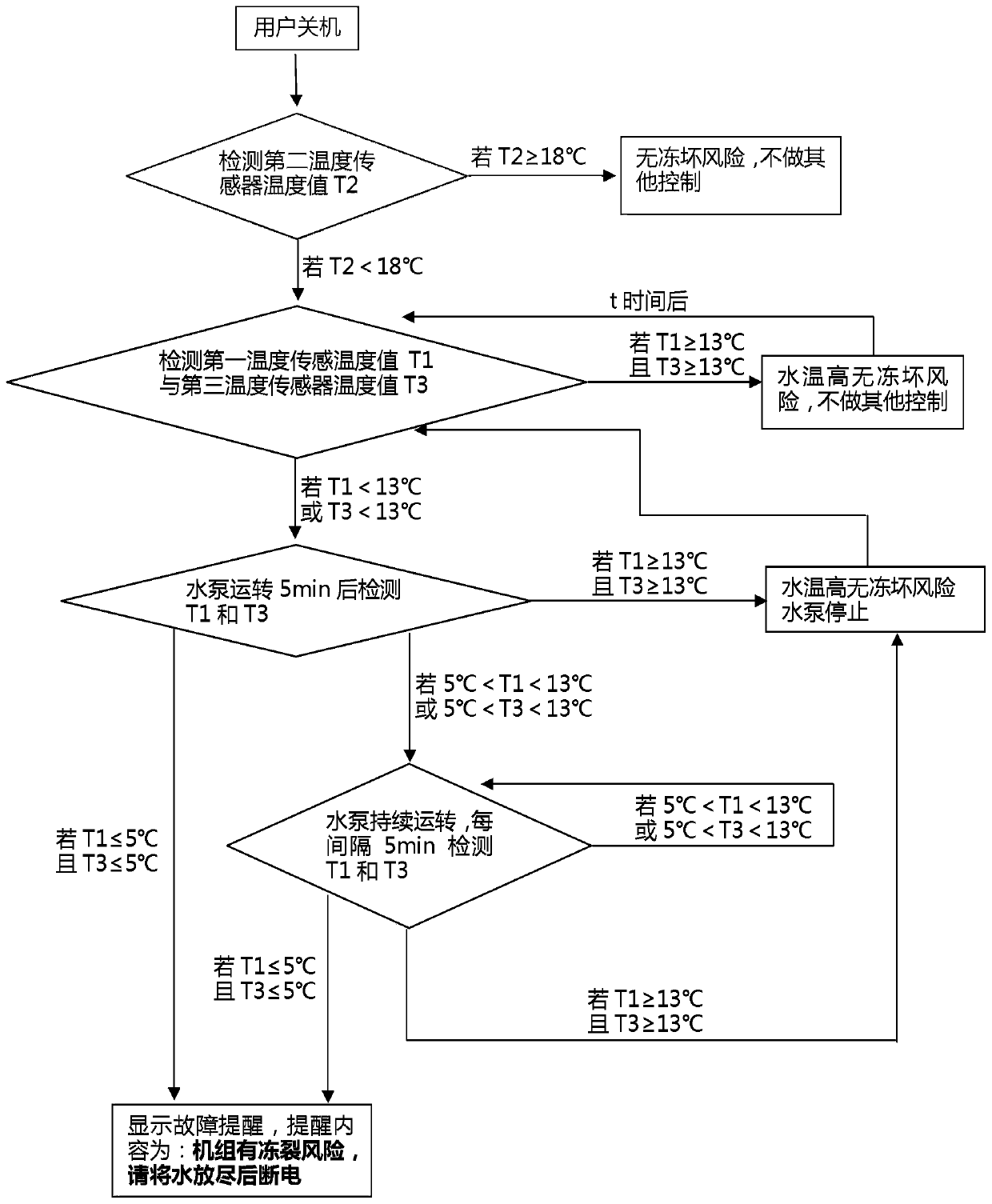

[0036] In a first exemplary embodiment of the present invention, an antifreeze control method for a fan coil unit is provided.

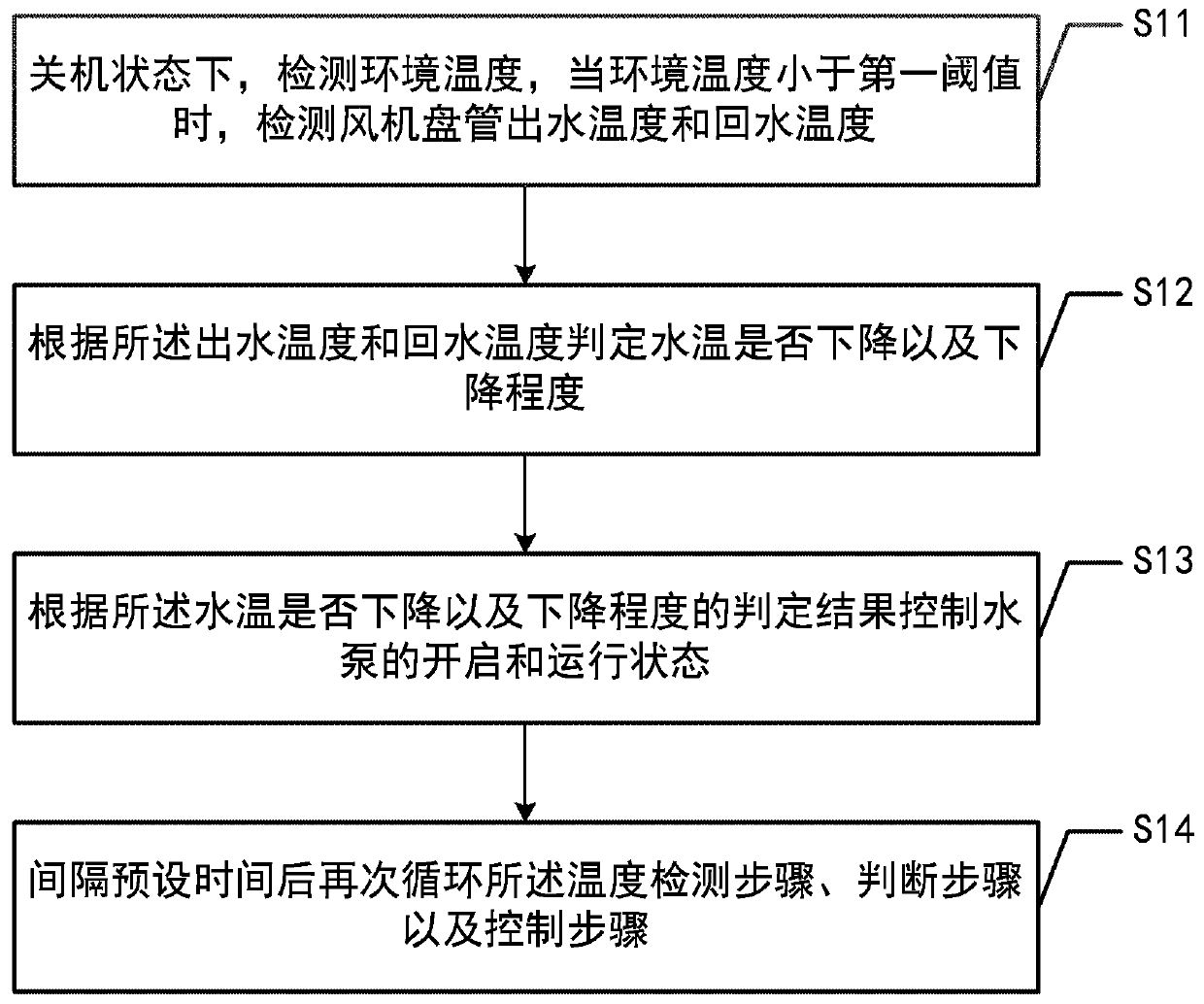

[0037] figure 1 It is a flowchart of an antifreeze control method for a fan coil unit according to an embodiment of the present invention.

[0038] refer to figure 1 As shown, the antifreeze control method of fan coil unit of the present invention comprises:

[0039] Temperature detection step S11: in the shutdown state, detect the ambient temperature, and when the ambient temperature is lower than the first threshold, detect the outlet water temperature and return water temperature of the fan coil unit;

[0040] In this embodiment, the first threshold value is 18°C. According to the "Code for Design of Heating, Ventilation and Air Conditioning in Civil Buildings", the design temperature of the interior environment of the building is ≥ 18°C. There is a risk of freezing, so the first threshold is set at 18°C.

[0041] Judging step S12: judging whe...

no. 2 example

[0056] In a second exemplary embodiment of the present invention, an air conditioner is provided, using the antifreeze control method of the present invention.

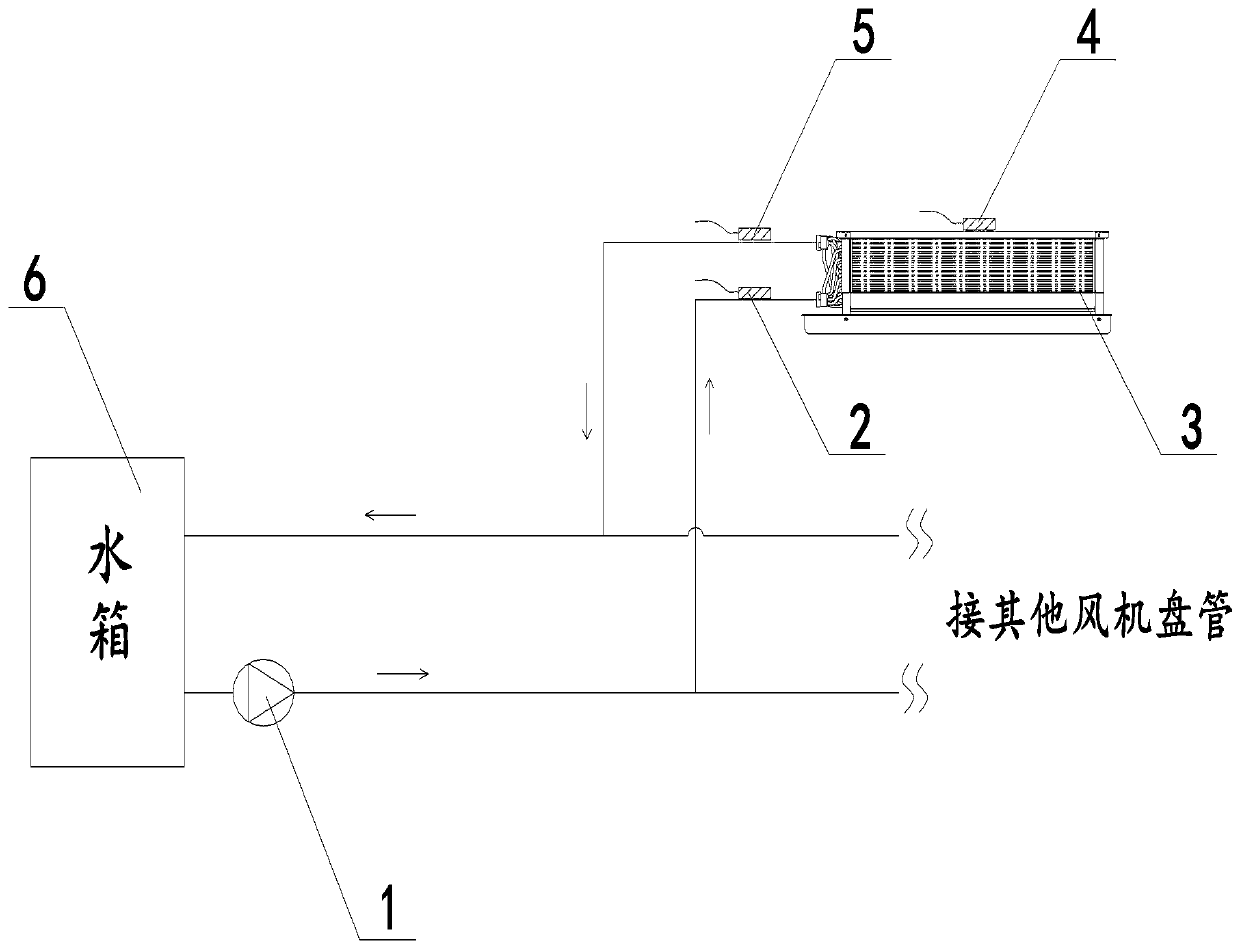

[0057] The air conditioner of the present invention includes a fan coil unit and three temperature sensors, two of which are installed on the water inlet and outlet pipes of the fan coil respectively, and the other is installed on the top of the fan coil for detecting environmental conditions. Temperature, the air conditioner also includes the water pump and water tank that are usually used in the fan coil waterway. Through the detection and judgment of the temperature sensor, the operation and opening of the water pump can be accurately controlled. When the water in the fan coil heat exchange tube can flow When getting up, the water will not freeze into ice, which solves the problem of freezing and cracking of the fan coil unit, thereby prolonging the service life of the fan coil unit.

[0058] figure 2 It is a sch...

no. 3 example

[0073] In a third exemplary embodiment of the present invention, an antifreeze control system for a fan coil unit is provided.

[0074] Figure 4 It is a block diagram of an antifreeze control system for fan coil units according to an embodiment of the present invention.

[0075] refer to Figure 4 As shown, the antifreeze control system of this embodiment includes: a temperature detection module, which is used to detect the ambient temperature in the shutdown state, and detects the outlet water temperature and return water temperature of the fan coil unit when the ambient temperature is lower than the first threshold; the judgment module, It is used to determine whether the water temperature has dropped and the degree of drop according to the outlet water temperature and the return water temperature; and a control module is used to control the start and operation status of the water pump according to the determination result of whether the water temperature has dropped and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com