Double-knife hinge support suitable for compression test

A hinge support, a pair of technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the difficulty of increasing precision control, large contact area between grooves and protrusions, and point hinges Rod out of the pit and other problems, to achieve the effect of strong adjustability, wide application range, high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

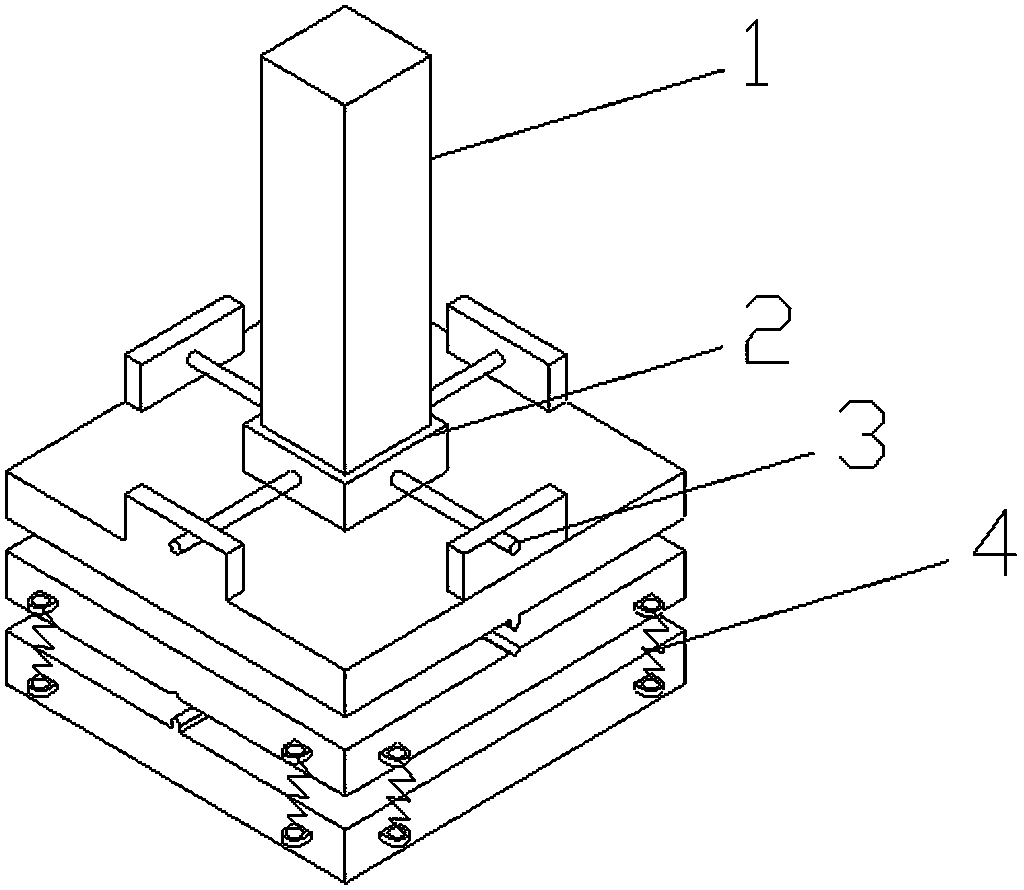

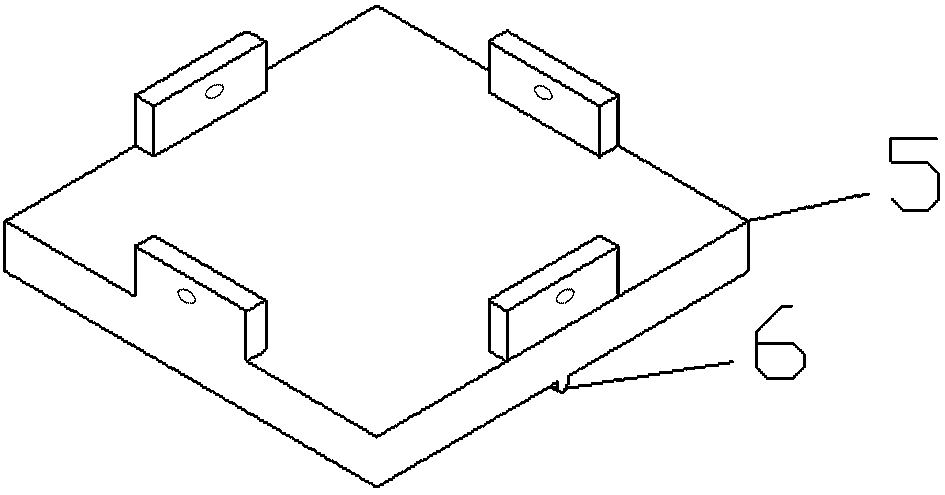

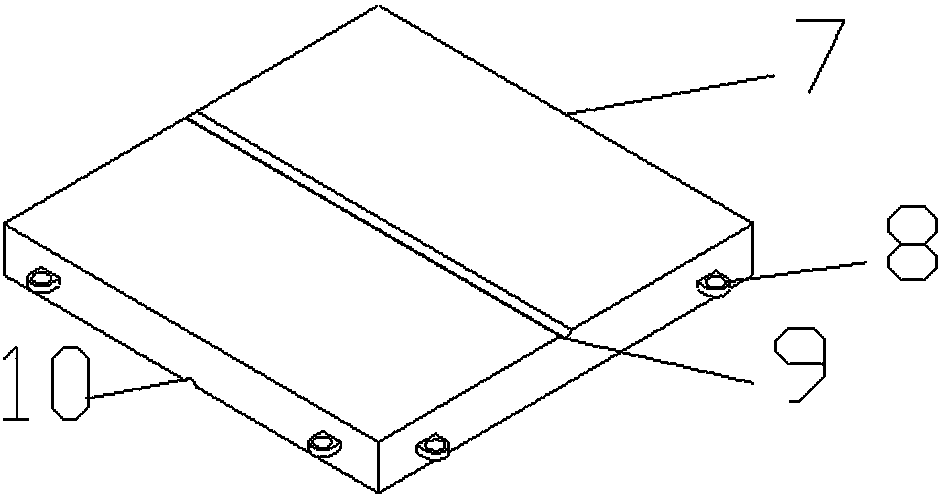

[0021] like Figure 1~6 As shown, a double-knife-hinge support suitable for compression tests includes a lower bottom plate 12, a middle bottom plate 7, and an upper bottom plate 5 stacked together, and a clamp for positioning the lower end of the component is installed on the upper side of the upper bottom plate 5. 2. The lower side of the upper bottom plate 5 and the upper side of the lower bottom plate 12 are provided with an orthogonal knife hinge 6, and the upper and lower sides of the middle bottom plate 7 are respectively provided with grooves that cooperate with the knife hinges on the upper and lower bottom plates 9. The four side edges of the upper surface of the upper bottom plate 5 are provided with a connecting plate 10 perpendicular to the upper bottom plate. The connecting plate 10 is provided with a threaded hole, and the bolt hole of the connecting plate 10 is pierced with an inward top end. Fixing bolts 3 on the side of the fixture, the clamping, the upper ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com